Full Text Searchable PDF User Manual

AromaMist

AromaMist

AromaMist

AromaMist

Pump

Model

AI-5

Installation and

Operation Manual

rev. 3z.9505

Page

2

AromaMist

AromaMist

AromaMist

AromaMist

Pump Model AI-5

Installation and Operation Manual

Table of Contents

I.

Introduction………………………………………………….…….

3

II.

Safety and Operating Information………………………………

3

III.

Pump Package Contents………………………………………..

4

IV.

Installation

A. Location……………………………………………………….

4

B. Mounting The Pump…………………………………………

4

C. Electrical………………………………………………………

5

D. Plumbing………………………………………………………

5

E. Control (Aroma Switch)……………………………………...

6

F. Typical Installation……………………………………………

7

G. Step By Step Installation………………………..……………

7

V.

Start-up

Priming the Pump……………………………………..…………

11

VI.

Operation Warnings………………………………………………

12

VII.

Operation………………………………………………………… 13

VIII.

Troubleshooting…………………………………………………. 14

Page

3

I. Introduction

Congratulations, you have just purchased the world’s most advanced aroma oil

metering pump, the

AromaMist

AromaMist

AromaMist

AromaMist

pump.

This instruction manual covers all facets of the installation and operation of the

AromaMist

AromaMist

AromaMist

AromaMist

pump including unpacking, mounting, electrical, plumbing, control, pump

connections, and start-up.

All information in these instructions is based on the latest product information available

at the time of publication. Accurate Industries Et Al., Inc. reserves the right to make

changes at any time without notice. Please read this manual completely before

proceeding.

Observe safety protocols and heed all warnings and precautions for safe and efficient

installation and operation of the

AromaMist

AromaMist

AromaMist

AromaMist

pump.

WARNING: It is recommended to have a certified licensed electrician

and plumber install the

AromaMist

AromaMist

AromaMist

AromaMist

pump system.

II. Safety and Operating Information

CAUTION: Please read this manual in its entirety prior to installing or

operating the

AromaMist

AromaMist

AromaMist

AromaMist

pump system.

A. Chemical Compatibility

AromaMist

AromaMist

AromaMist

AromaMist

metering pumps are designed to work with

AromaMist

AromaMist

AromaMist

AromaMist

oils only.

Failure to do so may void the warranty or pose serious health hazards.

B. Safety Equipment and Preparation

Always wear the proper protective clothing and gear when working around

chemicals and chemical metering pumps. Safety glasses, gloves, and aprons can

prevent accidental exposure to chemicals.

C. In Case of Accident

If a chemical spillage occurs, consult the Material Safety Data Sheet (MSDS) for

specific instructions regarding the chemical being used.

D. Liquids Under Pressure

Liquids under pressure can present a special hazard when a line or seal is

punctured resulting in the spraying of chemical many yards away.

E. Safe Installation

Do not install the

AromaMist

AromaMist

AromaMist

AromaMist

pump system without reading and understanding the

Operation Warning section (V) and Operation section (VII) of this manual.

Page

4

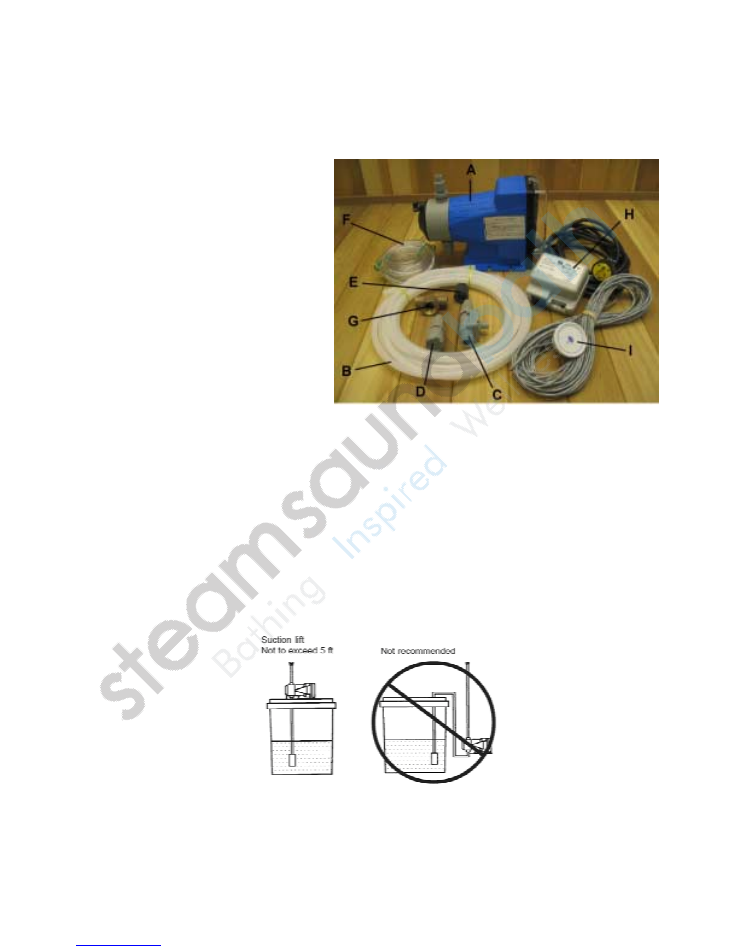

III. Pump Package Contents

AromaMist

AromaMist

AromaMist

AromaMist

Pump Package Contents

A.

AromaMist

AromaMist

AromaMist

AromaMist

Pump

B.

⅜

” Discharge/suction tubing, 20’

C.

3-function valve

D.

F

oot valve

E.

Ceramic weight

F.

⅜

” Vinyl priming tubing, 10’

G.

½” Brass T

H.

Power supply module

I.

Aroma switch

IV. Installation

A. Location

Select a pump mounting location convenient to the aroma oil supply and a source of

power for the pump. Do not install the pump in a location where the ambient

temperature exceeds 100 degrees Fahrenheit or where water can freeze. A location

that is locked or secure from children is highly recommended.

The

AromaMist

AromaMist

AromaMist

AromaMist

pump should be installed no more than five vertical feet above

aroma oil source. See Typical installation on page 7 of this manual.

B. Mounting The Pump

Secure pump with appropriate hardware (not provided) to shelf or stand using the

four (4) slots in pump base.

Page

5

C. Electrical

AromaMist

AromaMist

AromaMist

AromaMist

pump model AI-5 is a 120V AC pump and has a voltage regulated

internal power supply capable of operating in the range of approximately 95 to

135 VAC. Use a supply voltage of 100 to 120 VAC for best results. The 3-wire

grounded plug must be used with provided power supply module in a 3-wire

grounded wall outlet.

CAUTION: Never remove ground wire from plug.

CAUTION: Do not position power supply cord in direct contact

with steam line.

D. Plumbing

1. Tubing Connections

The

AromaMist

AromaMist

AromaMist

AromaMist

pump uses carefully matched components to achieve a

predictable metering output. This predictability can only be maintained if all fitting

sizes remain unaltered.

Do not

attempt to reduce tubing size. All tubing

connection should be double checked to insure against leakage.

CAUTION: Do not position tubing in direct contact with steam

line.

NOTE: When cutting lengths of tubing for your installation, ensure a

clean, square cut. Use short lengths of tubing whenever possible.

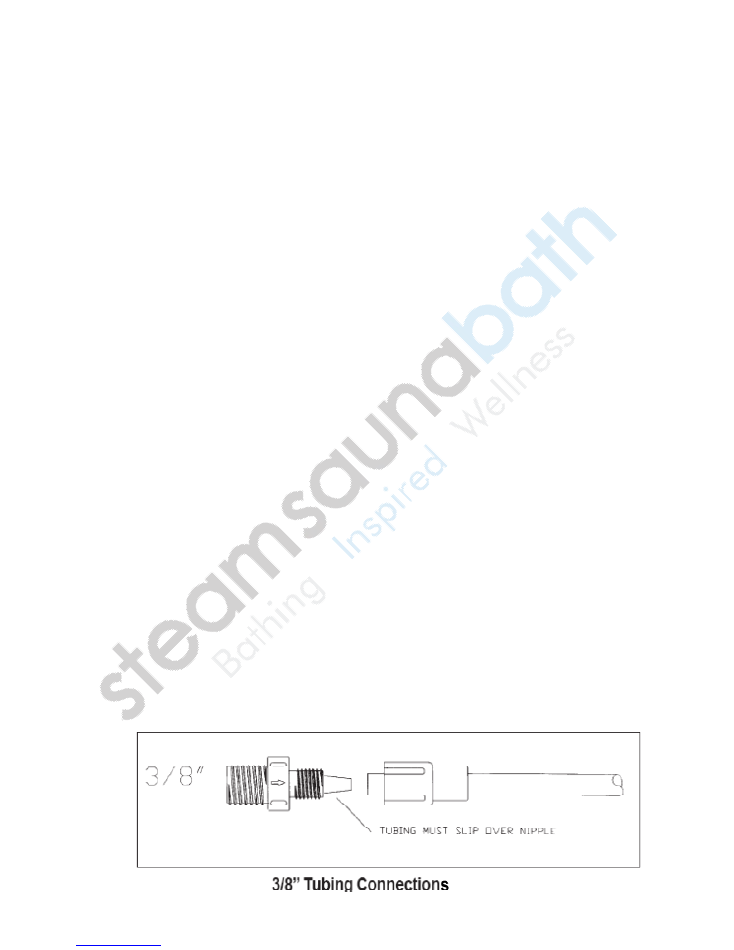

2. Tubing nuts

Do not over tighten tubing nut connectors. Tighten no more than ¼” turn after

the fitting contacts the seal. Hand tighten only.

Do not use a wrench or pliers

as they may damage the fittings. (See diagram below.) Do not use Teflon tape

except on 3-function valve NPT fitting.

Be sure to observe applicable local

plumbing codes.

WARNING: Clear flexible vinyl priming tubing is not intended for

pressurized or pump discharge use.

3. Tubing Connections

Page

6

E. Control (Aroma Switch)

1. Location

Determine the desired installation location for the aroma switch control. The

aroma switch has a 60’ integral low voltage cable and is designed to be installed

inside or outside the steam room as a matter of personal preference.

If aroma switch is installed inside the steam room, it must be located 4-5 feet

above the floor, on a vertical wall, convenient for user on/off operation and away

from steam head or steam emissions.

NOTE: For convenient use during steambathing, an aroma switch mounted

inside the steam room is most preferred.

2. Mounting Aroma Switch

Make a 1

⅝

” diameter hole in desired control location. Route the aroma switch

integral control cable from the wall cut out to the

AromaMist

AromaMist

AromaMist

AromaMist

pump power

supply module. With a clean and dry mounting surface, remove the peel-off

paper from the back of the aroma switch, run a thin bead of 100% clear silicon

completely around the aroma switch mounting flange and press the control

against the wall until the adhesive sticks. Connect the aroma switch cable to the

3-pin terminal on the power supply module to complete the aroma switch

installation.

Aroma Switch (Front View)

Aroma Switch (Back View)

Page

7

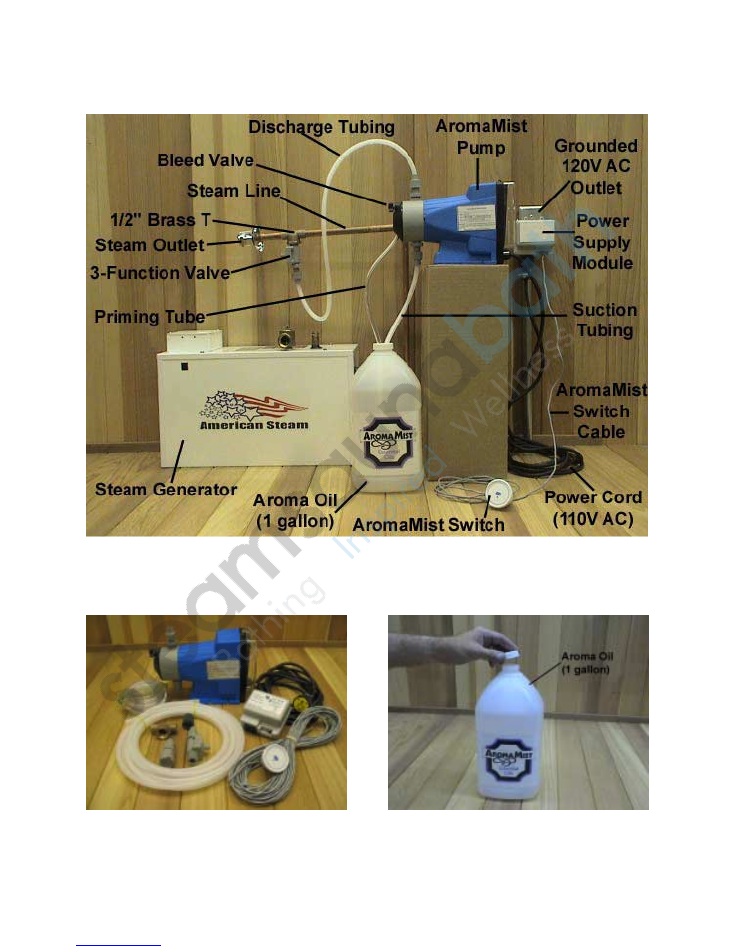

F. Typical Installation

G. Step By Step

AromaMist

AromaMist

AromaMist

AromaMist

Pump Installation

1. Verify carton components and mount

pump on a level surface. See details on

locating the pump on page 4 of this

manual.

2. Locate

AromaMist

AromaMist

AromaMist

AromaMist

brand aroma oil and

remove cap.

G. Step By Step

AromaMist

AromaMist

AromaMist

AromaMist

Pump Installation (continued)

Page 8

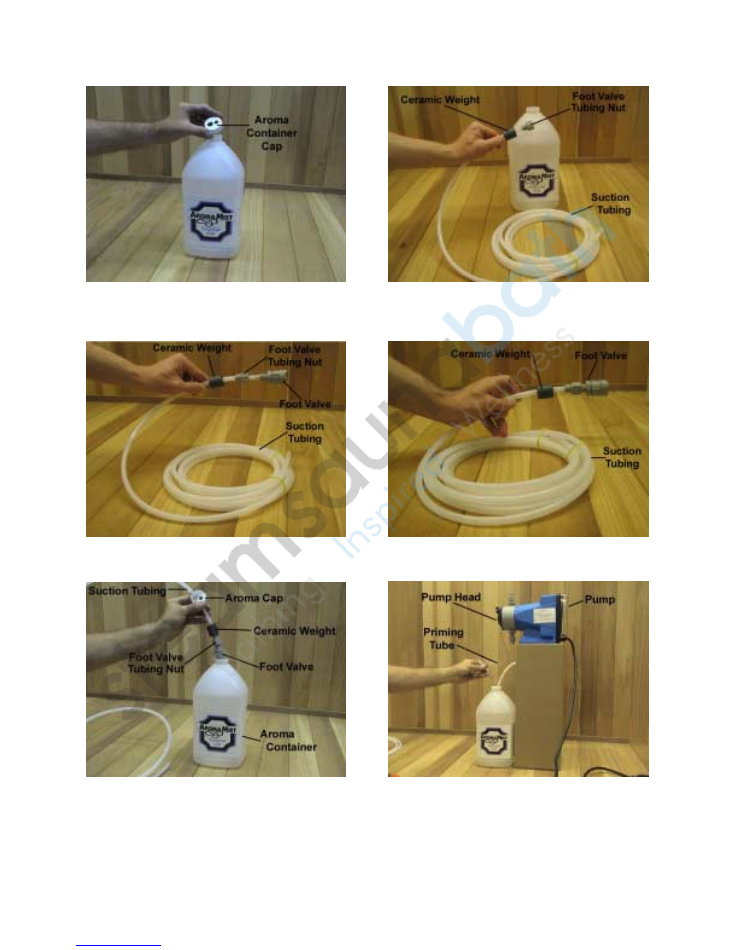

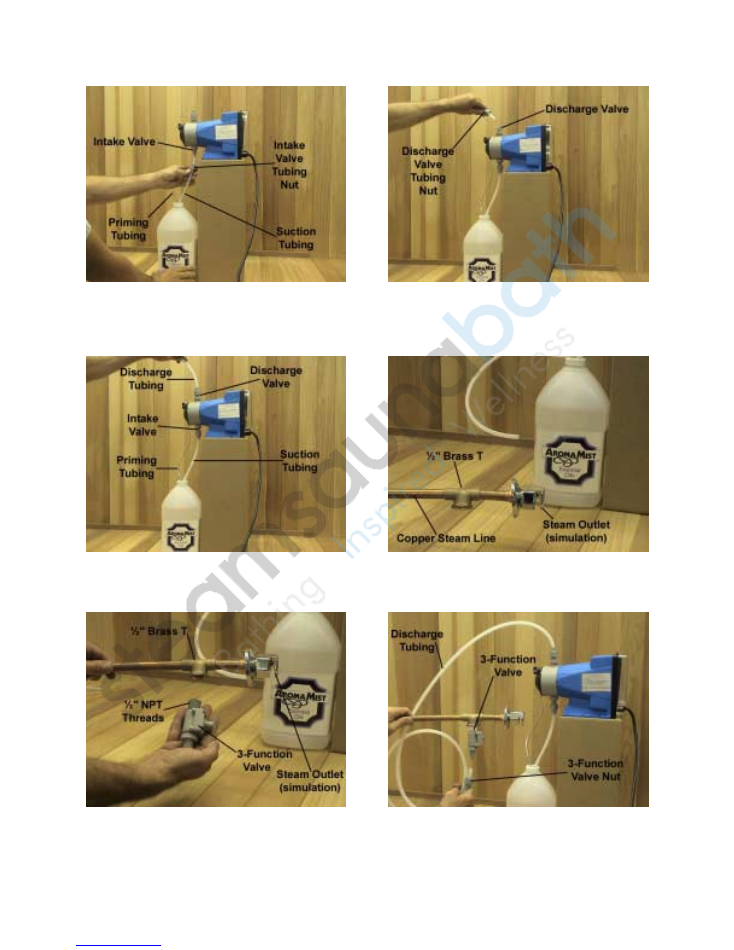

3. Drill 2 holes in aroma container cap:

one

⅜

" hole for clear vinyl priming tube

and one

7

/

16

" hole for the more rigid

suction tubing.

5. Install foot valve next, pushing firmly

until suction tubing is flush against foot

valve threads.

7. Thread suction tubing through aroma

container

7

/

16

" hole and insert

components into aroma oil container.

Foot valve should remain vertical and

resting on aroma container bottom.

4. Beginning with the more rigid 20'

suction tubing, cut the required length

necessary and string the ceramic weight

followed by the foot valve nut.

6. Secure foot valve nut. Hand tighten

only.

8. With aroma container located beneath

pump head and cap secure, insert clear

vinyl priming tube through

⅜

” hole in

cap to bottom of aroma container.

G. Step By Step

AromaMist

AromaMist

AromaMist

AromaMist

Pump Installation (continued)

Page 9

9. Remove intake valve tubing nut and

red protective cap, slip nut on the

suction tubing, secure suction tubing on

intake valve and hand tighten intake

valve nut.

11. All pump priming, discharge and

suction tubing connections should

appear as detailed above.

13. Locate 3-function valve, apply Teflon

tape or joint compound to ½” NPT

threads and secure 3-function valve in

bottom of ½” T.

10. Cut required length of discharge

tubing, remove discharge valve tubing

nut and red protective cap, slip nut on

discharge tubing, secure discharge

tubing and hand tighten nut.

12. Cut existing steam generator steam

line and solder in provided ½” brass T.

Steam outlet head shown for illustration

purposes only.

14. Remove 3-function valve tubing nut,

slip nut on discharge tubing and hand

tighten nut to 3-function valve.

G. Step By Step

AromaMist

AromaMist

AromaMist

AromaMist

Pump Installation (continued)

Page 10

15. All pump connections should appear

as detailed above. Steam head shown

for illustration purposes only.

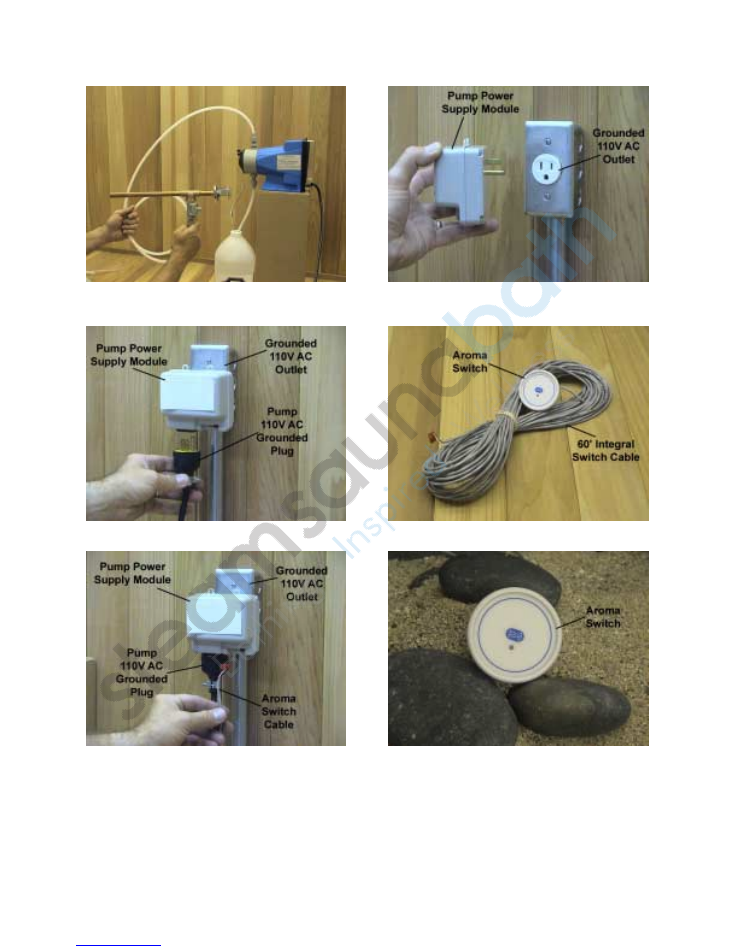

17. Plug in pump 110V AC power supply

cord to power supply module.

16. Run a 110V AC grounded outlet

within 6’ of pump installation location

and insert pump power supply module.

18. Locate pump switch with integral 3-

pin 60’ low voltage cable

19. Cut a 1

⅝

” hole in desired switch

installation location and run control

cable from switch mounting hole to

power supply module 3-pin connection

terminal pressing firmly to affix cable.

See page 6 for control installation

details.

20. After testing pump switch for

operation, secure in newly created 1

⅝

”

diameter hole using 100% clear silicon

and let dry for 24 hours prior to use.

Page 11

V.

Start-Up -

Primimg the

AromaMist

AromaMist

AromaMist

AromaMist

pump

CAUTION: Please read all 7 steps prior to priming the

AromaMist

AromaMist

AromaMist

AromaMist

pump

1.

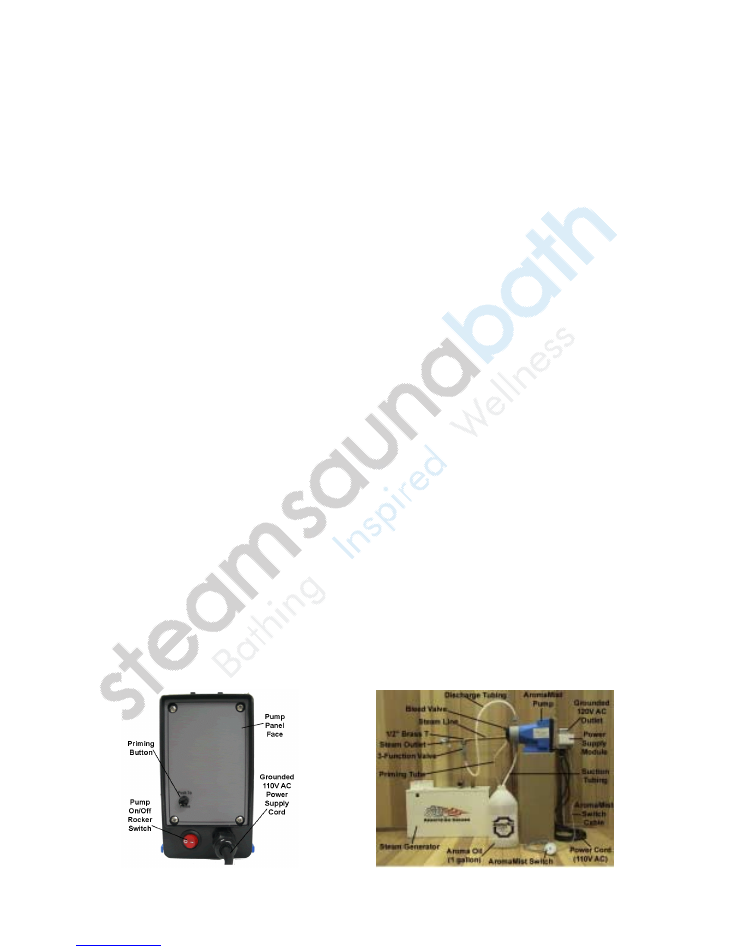

Insert

AromaMist

AromaMist

AromaMist

AromaMist

pump power supply cord into pump power supply module.

2.

Insert

AromaMist

AromaMist

AromaMist

AromaMist

pump power supply module into grounded 110V AC outlet.

3.

Power up integral

AromaMist

AromaMist

AromaMist

AromaMist

pump rocker switch located on the pump panel

face. Switch LED will light when on.

4.

Initiate the remote-mounted aroma switch by pressing gently on jet icon.

Aroma LED will light when on and pump will start moving aroma oil.

5.

With

AromaMist

AromaMist

AromaMist

AromaMist

pump on, push and hold the priming button located on the

pump panel face. This will initiate the priming process where aroma oil will be

drawn at a faster rate to fill the suction and discharge tubing. Releasing prime

button will stop priming process.

6.

With pump in priming mode, if fluid begins moving up suction tubing without

hesitation, bleed valve adjustment is not required. If fluid is not moving up suction

line, open bleed valve (counter-clockwise) approximately one (1) turn or until fluid

begins to move. When fluid level reaches the pump head assembly, close bleed

valve allowing fluid to flow through pump head and up to the steam line.

NOTE:

Do not over tighten bleed valve as damage may occur.

7.

Once aroma oil has reached the 3-function valve, release the priming tubing

and turn off the remote-mounted aroma switch.

AromaMist

AromaMist

AromaMist

AromaMist

pump is now ready

for use.

NOTE: Pump integral On/Off rocker switch must stay in the on position to

operate pump from remote-mounted aroma switch.

Page 12

VI. Operation Warnings

1. Do not use a sharp object or fingernail to press on the

AromaMist

AromaMist

AromaMist

AromaMist

pump switch.

Sharp objects will penetrate the face plate and damage the aroma switch.

2. Do not pump unapproved aroma oils with the

AromaMist

AromaMist

AromaMist

AromaMist

pump system. Use of

foreign oils may pose serious health hazards or damage to equipment.

3. Check with a physician prior to using the

AromaMist

AromaMist

AromaMist

AromaMist

pump system if you are

pregnant, have a coronary condition, are in poor health, are using medications or

drugs, have allergies or are being treated for any other medical conditions.

4. Children under the age of 17 should not use a steambath.

5. Exit the steam shower immediately if you feel uncomfortable, faint, dizzy or tired.

6. Aroma oil residue, steam shower condensation and moisture will cause the

steam room floor and other surfaces to become slippery. Installation of non-skid

floor materials and caution while walking is always recommended.

7. Do not walk near or by steam outlet head during steam shower operation.

8. Do not activate the

AromaMist

AromaMist

AromaMist

AromaMist

pump while the steam generator is off or not

producing steam. If pump is accidentally activated with steam generator off,

operate steam generator for 10 minutes with aroma switch in the off position to

flush the steam line. Follow with water spray to wash the steam shower floor of

excess aroma oil residue.

9. Aroma oil is an oil-based product which will make the steam shower floor

slippery. It is important to wash down floor with water immediately after each use

and use caution while walking.

10. Should you have any questions about the safe installation or operation of the

AromaMist

AromaMist

AromaMist

AromaMist

pump system, we encourage you to call us at (847) 465-8990.

Page 13

VII. Operation

During the steambath session, initiate the

AromaMist

AromaMist

AromaMist

AromaMist

pump by pressing the mist icon

below the on/off LED indicator light on the aroma switch. Once activated, the red LED

will light and the aroma oil will begin to flow into the steam line.

Once satisfied with the steam shower aroma, depress the aroma switch once again to

stop the flow of aroma oil. The red on/off LED will indicate the pumps status at all

times. Start and stop the aroma oil flow as required to maintain the desired steam

bathing fragrance.

NOTE: Frequent starting and stopping of aroma oil will not adversely affect the

AromaMist

AromaMist

AromaMist

AromaMist

pump.

The

AromaMist

AromaMist

AromaMist

AromaMist

pump has no adjustment for aroma oil flow rate. For increased

fragrance intensity, initiate the aroma switch earlier in the steambathing session.

NOTE: The

AromaMist

AromaMist

AromaMist

AromaMist

pump system has a built-in timer and, if not manually

turned off, will automatically operate for a 10-minute session.

For care of your aroma switch, only use mild soap and water on a soft cloth. Do not use

any abrasive or chemical cleansers.

CAUTION: Aroma oil is an oil-based product which will make the steam shower

floor slippery. It is important to wash down floor with water immediately after

each use and use caution while walking.

Page 14

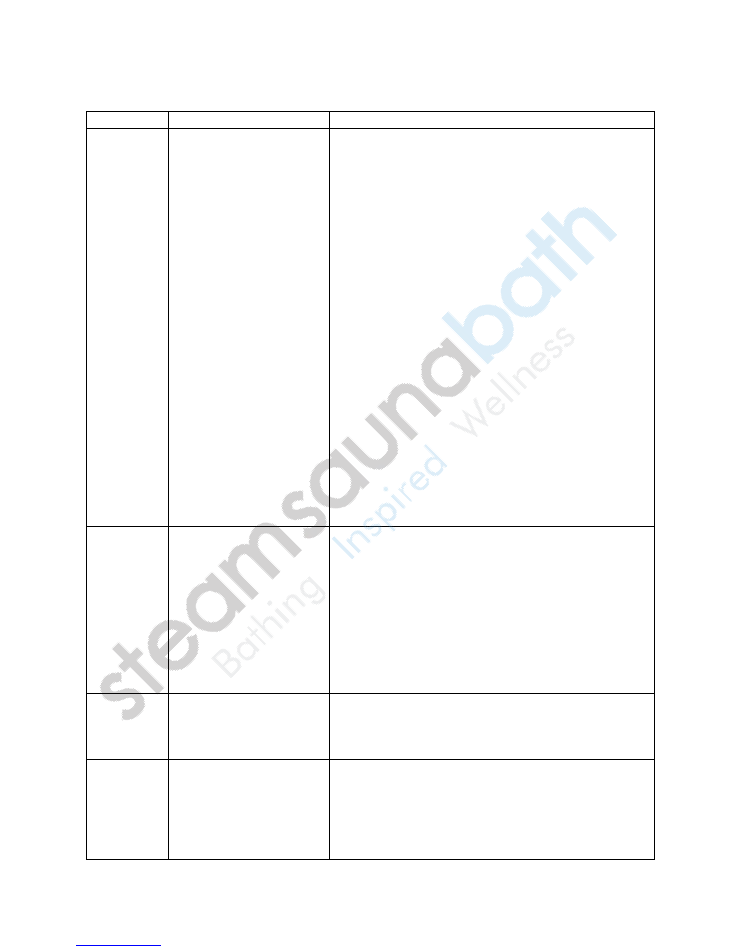

VIII. Troubleshooting

Problem Cause

Remedy

Pump

does not

achieve or

maintain

prime

Air Trapped in suction

line

Foot Valve

contaminated or

improperly installed

Excessive lift

Suction fittings not

properly tightened

Worn or contaminated

check valves

Kink or pinch in

suction tube

Low chemical level

Straighten suction line so as to eliminate high

spots

Inspect foot valve screen and assure that foot

valve is in a vertical position below fluid level

Maximum suction lift is 5 feet with water or fluids

of similar specific gravity; less with heavier

liquids such as acids. Mount pump in a lower

position relative to the chemical container.

Check fittings. Over tightening may cause

restriction. Conversely, if

any

leakage occurs,

pump will suck air and fail to prime.

Inspect check valves in fluid end for cleanliness.

Clean or replace as necessary.

Inspect suction tube through its full length to

assure that there are no kinks or other

restrictions

Check fluid level in chemical supply tank

Insufficient

fluid

Obstruction in suction

line

Clogged foot valve

screen

Diaphragm worn or

torn

Electronic failure

Check suction line for obstructions, clogging,

kinks or pinch points

Clean or replace foot valve screen

Replace diaphragm, making sure that it is

screwed on fully to shoulder of shaft

Consult factory

Excessive

fluid

Failure of anti-siphon

valve

Improper stroke length

Inspect or add anti-siphon valve. This is caused

when system is in a vacuum condition.

Consult factory

Pump will

not run

Pump not turned on or

not plugged in

Electronic failure

Check outlet with meter to assure that 95-135

VAC is present on 120V systems and that the

power supply cord is in good condition and

plugged in

Consult dealer or factory

Page 15