Full Text Searchable PDF User Manual

CAUTION:

Read a

nd Save These Instructions

.

owner’s manual

Make-up Air Blower and/or

Evaporative Cooler

(Models SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2)

Installation • Operation • Maintenance

Form #MABEV0312

(800)-288-0892

3328 Interurban Road

Denison, TX 75020

Fax (903) 463-1235 • www.aresmakeupair.com • info@aresmakeupair.com

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

2

T

el: (800)-288-0892 • www.aresmakeupair.com

Contents

General Info rmation

TO INSURE PROPER OPERATION AND MAINTENANCE OF ARES SC1/SC2/SC3, SE1/SE2,

DC1/DC2 and DE1/DE2 MODELS, PLEASE READ AND UNDERSTAND THIS MANUAL THOROUGHLY.

Where necessary, the following information will be indented and paraphrased.

NOTE:

Information pertaining to special instructions regarding the care and use of the ARES models.

SC = Blower horizontal discharge with filtered inlet louvers

DC = Blower pointed down through the pan with filtered inlet louvers

SE = Blower horizontal discharge with evaporative cooling media and louvered intake

DE = Blower pointed down through the pan with evaporative cooling media

CAUTION:

Information intended to

indicate situations which may cause immediate or future

WARNING:

Advice against improper use or procedures which may result in bodily injury

All information illustrations

and specifications contained in this manual are based on the latest product

information available at the time of printing. ARES reserves the right to make changes at the time,

without notice, in specifications and models and also to discontinue models. ARES also reserves the

right to change any specifications or parts at any time without incurring any obligation to equip the

same on models manufactured prior to date of such change.

The continuing accuracy of this manual cannot be guaranteed.

All illustrations used in this manual may not depict actual models or equipment and are intended as

representative views for reference only.

Future supplement sheets will be added or deleted as necessary.

Prints or system details located in this manual are for instructional purposes only and do not represent

damage to the ARES SC/SE/DC/DE models.

for which ARES will accept no responsibility.

WARNING:

To Reduce the Risk of Electric Shock, Do Not Use This Fan With Any Solid State Speed Control Device.

The nomenclature is as follows:SC/SE/DC/DE

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

a. Use this unit in the manner intended by the manuafacturer. If you have questions, contact

the manufacturer.

b. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting

means to prevent power from being switched on accidentally. When service disconnecting means

cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

c. Installation work and electrical wiring must be done by qualified person(s) in accordance with all

applicable codes and standards, including fire-rated construction.

Pre-Installation. .................................................................................................................................................. .3

Installation.......................................................................................................................................................... 4

Ductwork. ............................................................................................................................................................ 4

Ceiling Register ................................................................................................................................................. .4

Evaporative Cooling ........................................................................................................................................... 5

Electric ............................................................................................................................................................... 5

Optional Accessories ......................................................................................................................................... 6

Start-Up Report ................................................................................................................................................. 6

Trouble-Shooting Guide .................................................................................................................................... 7

Maintenance and Cleaning ................................................................................................................................ 7

Preventative Maintenance Chart ........................................................................................................................ 9

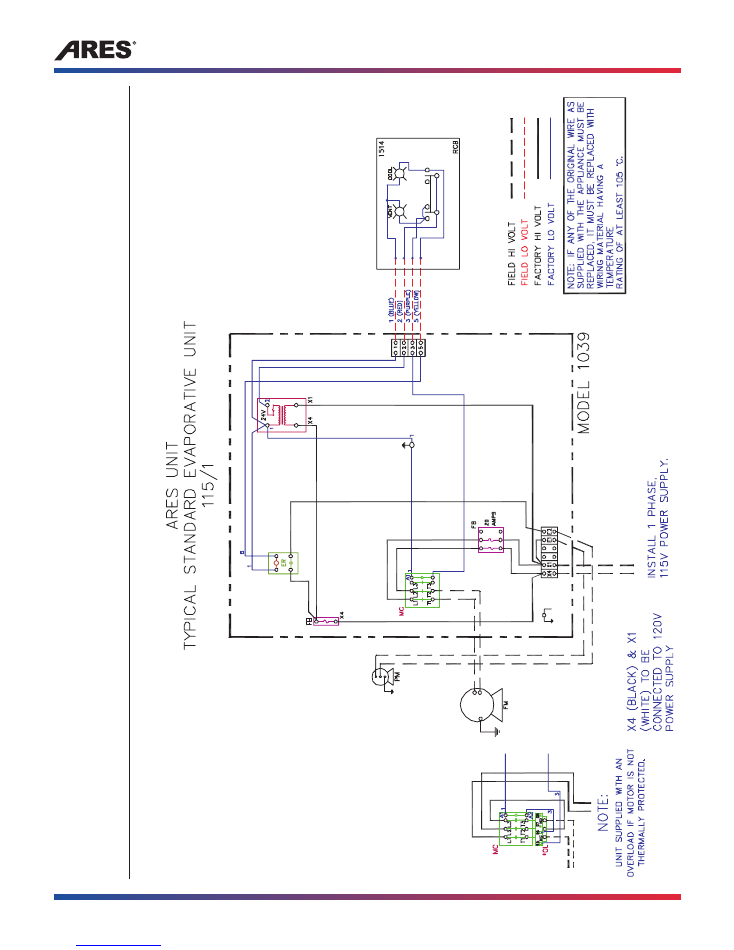

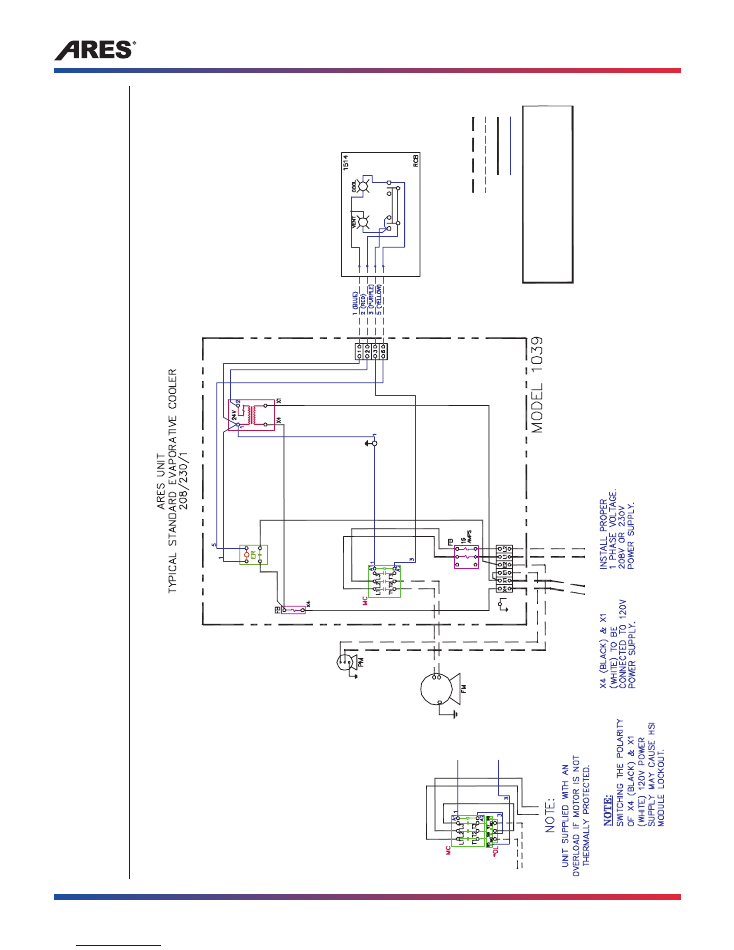

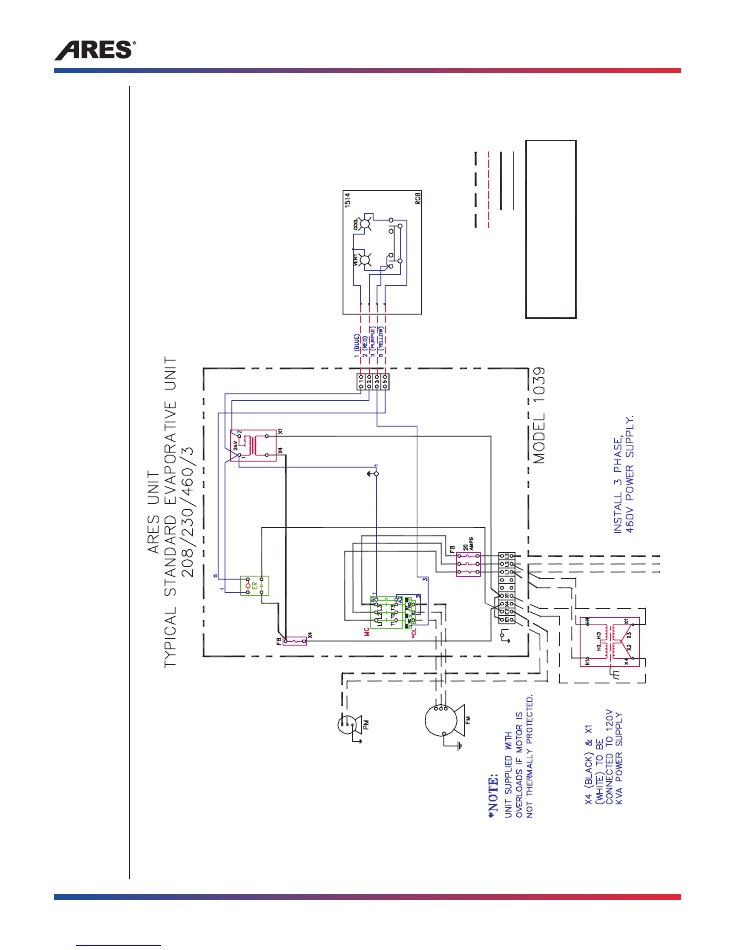

Wiring Diagrams ............................................................................................................................................... 10

Parts List .......................................................................................................................................................... 13

Service and Ordering Information .................................................................................................................... 14

Limited Warranty .............................................................................................................................................. 15

Owner Registration .......................................................................................................................................... 16

Warranty Registration ....................................................................................................................................... 17

AVERTISSEMENT:

Ne Convient Pas à Des Régulateurs de Vitesse à Semi-Conducteurs.

actual or scale drawings.

PRE-INSTALLATION

CODES

Check all applicable codes regulations and permits for installation requirements. Installation must

comply with utility regulations and local codes as well as those of the National Fire Protection

Associations 90A or 90B as applicable.

NOTE: Building of safety codes may require that exhaust fans be interlocked with the make-up air

unit. This requirement is satisfied with an optional ARES exhaust fan control relay assembly or

interface panel.

UNIT INSPECTION

Check unit for shipping damage. If damage is found, report it immediately to the carrier and file a

damage claim.

ROOF LOAD

Roof load-bearing capacity must be adequate to handle the operating weight of the make-up air unit. To

spread this load over additional roof joints and to support the unit above accumulated rainwater, 8"

mounted rails are frequently used.

Check roof loading and structure for support. Approximate operating weights are shown below.

BLOWER

HOISTING

OPERATION

AVG. ROOF

WEIGHT

WEIGHT

LOADING

(Approx. lbs.)

(lbs.)

(PSF)

SE1/DE1

470

612

44.8

SC1/DC1

470

470

34.4

SE2/DE2

490

632

46.2

SC2/DC2

490

490

35.8

SC3

525

525

30.5

Hoisting weight includes crate. Operating weight includes water. Hoisting eyes are included to lift the

make-up air unit to the roof.

LOCATION

1. In a roof installation, units should be installed level on a roof curb, rails or roof stand (minimum 4"

high) to allow ventilation beneath the unit. Adequate space for a water drain connection is required

beneath the sump pan of the cooling section, which is also a 4" minimum.

2. If adequate air supply volume is provided, the unit may also be installed on a sidewall. Exact

location will depend upon building construction and the placement of ceiling registers and ducts.

These should be placed carefully to provide maximum distribution of make-up before it is drawn

into the exhaust systems.

3. Install the unit as close as possible to the supply register to minimize duct system resistance (total

external static pressure loss through the duct.)

4. Be sure the unit’s capacity is equivalent to the demands of the systems.

5. Duct velocity should not exceed 1500 FPM.

6. Do not install unit near plumbing vent pipes and exhaust stacks.

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

3

Tel: (800)-288-0892 • www.aresmakeupair.com

7. Natural air circulation must be permitted around the unit at all times.

NOTE: Provide a minimum of 36" clearance at all times around the unit for service access to

Filters, Blower, and Motor and for air circulation.

8. A suitable electrical disconnect switch needs to be installed somewhere in plain view of the

equipment for servicing purposes (this is not a code requirement in all localities, it is a safety

recommendation).

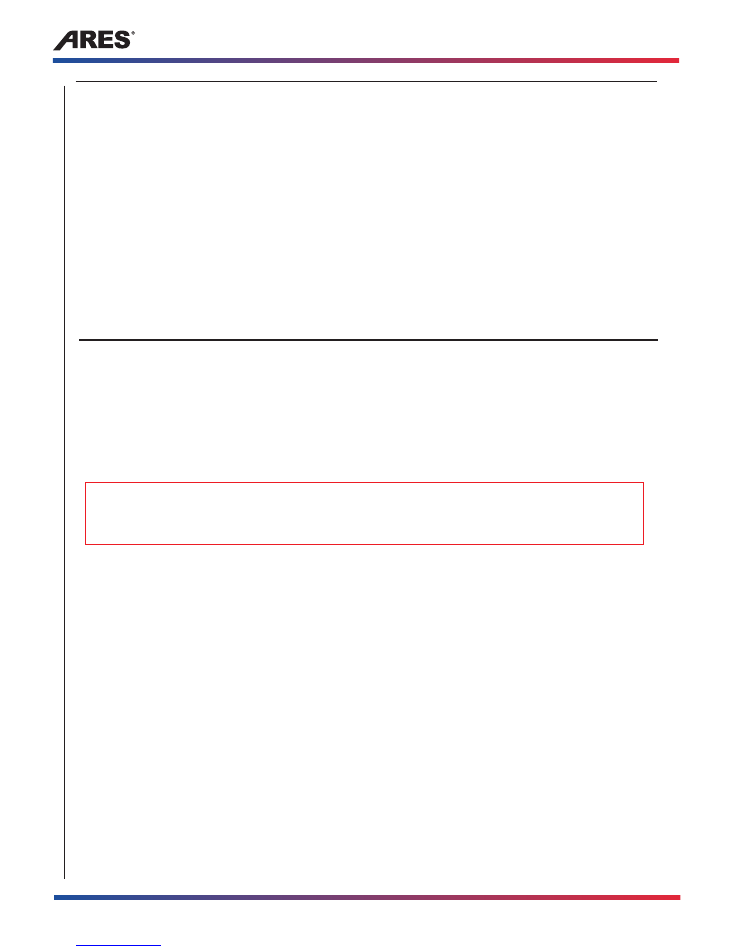

HOISTING EYE INSTALLATION

Remove the blower pad frames.

Position the hoisting eyes on corners of the unit with the angle towards the

center of the unit. (See illustration at right)

Run the bolt through the unit housing and hoisting eye, then attach the nut.

(See illustration at right).

INSTALLATION

DUCTWORK

1. Sizing and layout of ductwork and outlets should provide maximum uniform airflow throughout the

area. Make-up air should be introduced at a location inside the area, but as far away from existing

exhaust hoods as possible to permit conditioned air to flow throughout the entire area before

reaching the exhaust zone, or unless connected to an engineered make-up air system.

2. Ductwork must be adequately sized and designed for minimum resistance (static pressure) to

provide required airflow. Check rating plate for minimum allowable CFM.

3. To avoid pressure losses, all short radius rectangular elbows should have turning vanes, offsets

should not be avoided, and small ducts and takeoffs should be undersized.

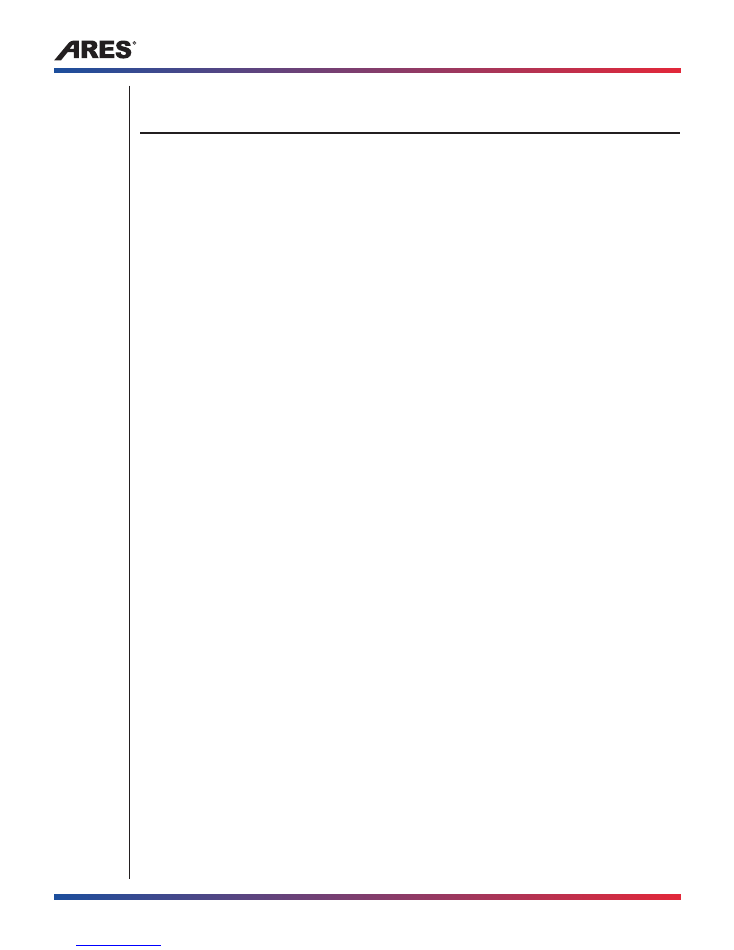

4. Main supply duct normally consists of a rectangular vane elbow at the unit and vertical duct

extension, both pieces having the same dimensions as the unit discharge opening. The ductwork

gauge size must be according to local codes. Ceiling registers should be the fixed type (if

adjustable, modify so full closing is not possible). (See illustration below)

CEILING REGISTER

With the make-up air unit in place on the floor, and

the framed roof opening installed:

1. Position roof jack over the opening.

2. Caulk and attach the transition elbow to the

unit with a flexible connection.

3. Push the extension duct up until it slides

through the roof jack into the transition elbow

(the bottom flange of the extension duct

should fit flush with ceiling). Seal, caulk and

secure into place.

4. In the building, center the box over the

opening and secure it.

5. Protect outdoor ductwork with weatherproof

insulation material.

6. This is ARES recommendation but you should

always check local codes in your area.

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

4

Tel: (800)-288-0892 • www.aresmakeupair.com

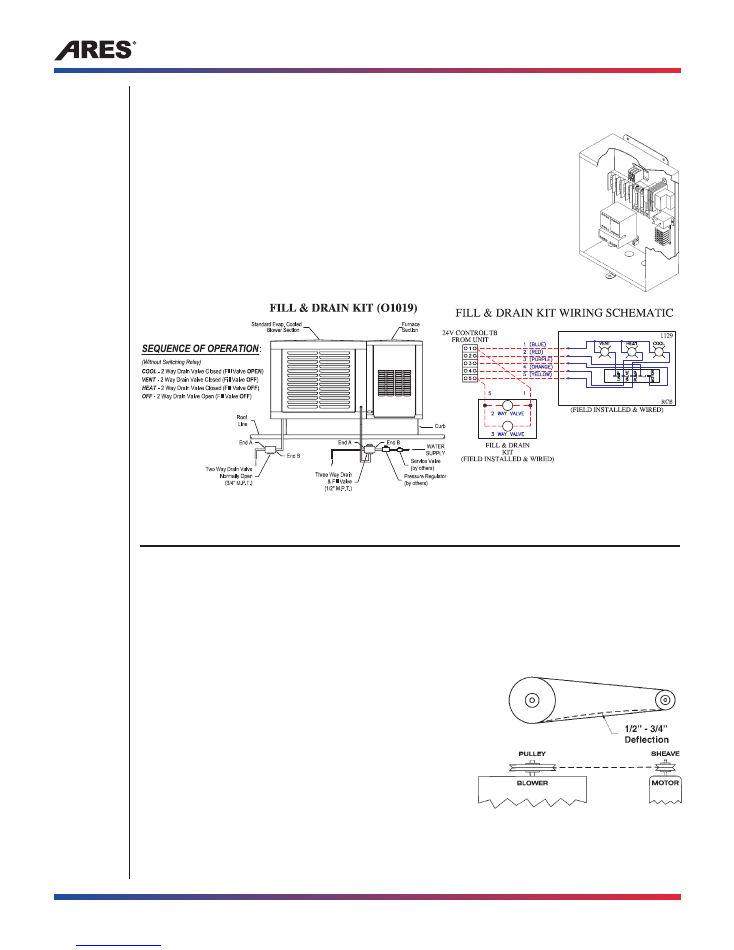

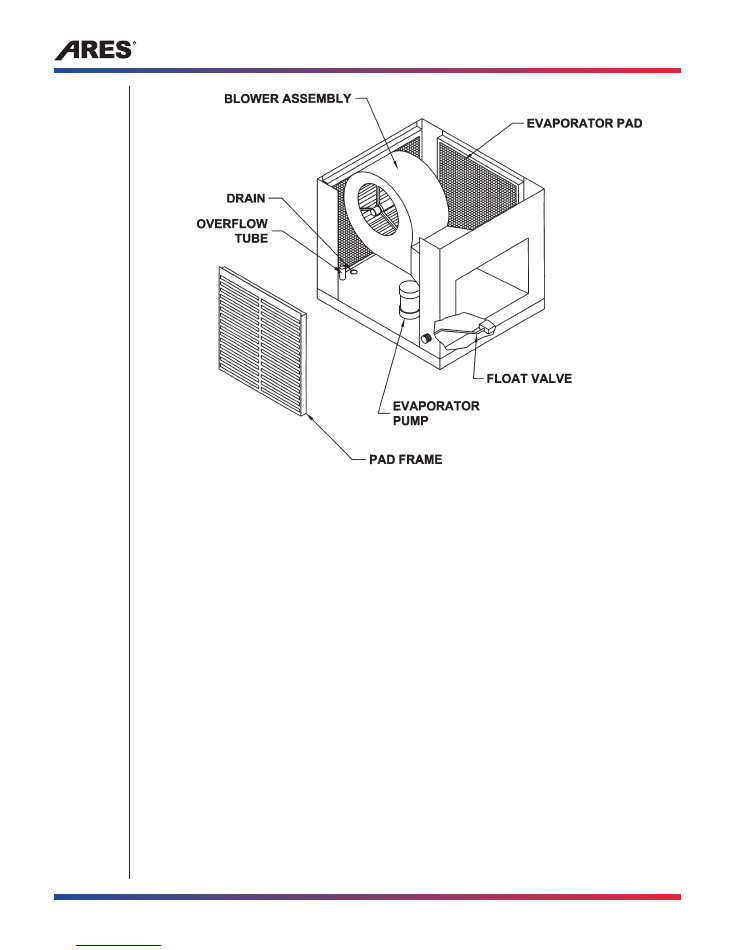

SE AND DE EVAPORATIVE COOLING

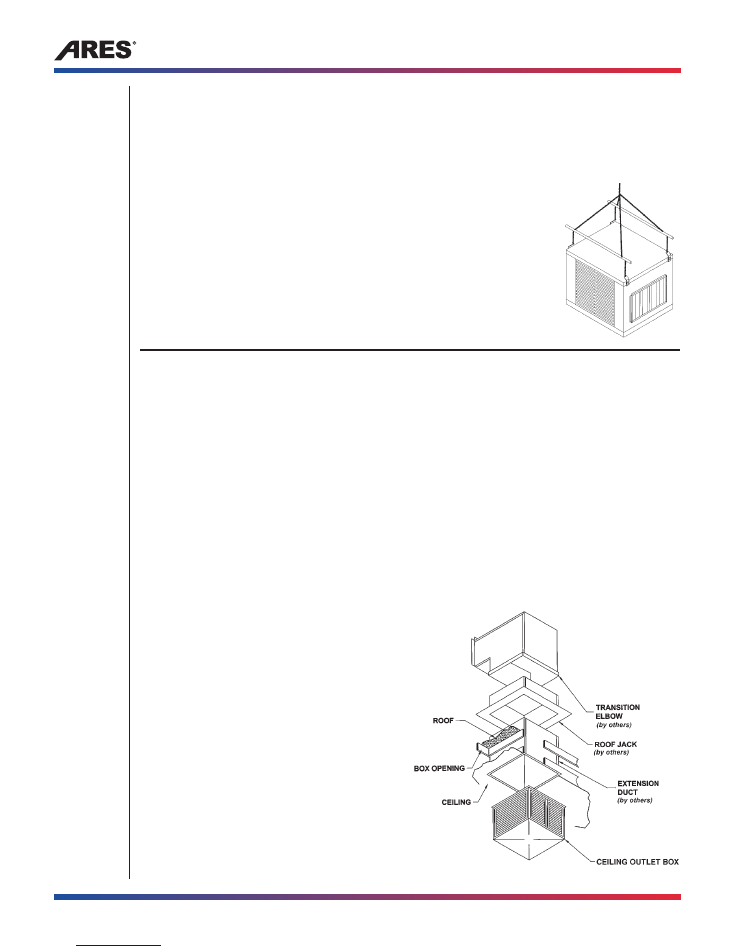

WATER SUPPLY: Water is circulated by a sump pump to troughs above the cooling media. It then flows

by gravity through “V” shaped slots and saturates the cooling filters. A float valve assembly replaces

water lost by evaporation. To avoid build up of organic minerals and salts in the sump, an adjustable

bleed-off valve directs a small stream of water through the overflow drain. An optional fill and drain kit,

which consists of a 3-way valve, 2-way valve and relay itemized for freeze protection of the Make-up Air

Unit water line, is available for field installation.

CAUTION:

Damage caused by not correctly installing and servicing the bleed-

off pipe is not covered by the ARES warranty.

Use an inside cold water line that has not passed through a water softening system because salts will

create additional maintenance and upkeep.

1. Install a 1/2" water piping to the right front support leg of the unit. Include a convenient shut-off

valve and provisions for draining to prevent freezing in the piping layout.

2. Install the overflow standpipe in the sump drain (supplied with the unit).

3. Install a drain line between the overflow standpipe (in the sump drain) to a suitable drain (check

local codes).

4. Install float valve assembly through the hole provided in the blower-cooler unit and adjust it so the

water level is approximately 2" deep in the sump pan. (See illustration below).

CAUTION:

Damage caused by incorrect water level in sump pan is not covered

by the ARES warranty.

5. Adjust the bleed valve to bypass the main water

line to rid the system of organic and mineral

deposits. (See illustration above)

ELECTRICAL INSTALLATION

1. Check the electrical ratings stamped on the serial

plate to be sure they are correct for use with

available electricity.

CAUTION:

Damage caused by incorrect power

supply is not covered by the ARES warranty.

2. The installed unit must conform to all codes and

regulations applying to the job site including

requirements of State and local agencies. All

wiring, grounding and connections must comply with

the

most current version of the

National

Electric Code. Permits

should be obtained prior to installation.

3. External controls must be provided to start and stop the fan motor and pump (E models only). An

external mounted starter should be used for motors.

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

5

Tel: (800)-288-0892 • www.aresmakeupair.com

4. Connect power to the motor leads provided. See nameplate for proper voltage and frequency.

5. Check the blower for proper rotation. Interchanging any 2 leads on 3-phase model only may

reverse rotation. Check motor nameplate for single phase.

6. On cooling models, connect the pump leads to the appropriate power

supply. See nameplate for the proper motor voltage.

OPTIONAL ACCESSORIES

The interface panel provides pilot duty switching circuits for interlock operation

of exhaust fans with make-up air units for one or two speeds. (See illustration

at right).

The fill and drain kit provides filling and draining of the sump pan. (See

illustration below)

OPERATION

INITIAL START-UP

1. Check electrical power against the unit’s nameplate.

2. Check airflow through the unit.

3. Re-check that the stand pipe and bleed-off kit have been correctly installed. The adjustable motor

sheave should be adjusted to provide the correct blower wheel RPM to attain the airflow at the

inherent system resistance. Adjust the sheave so the airflow is at or above the minimum shown on

the nameplate. See illustration at right.

4. Check belt tension and alignment. When installing the

belt or adjusting tension, loosen the four motor mounting

bolts and reposition the motor until the belt can be

deflected 1/2" to 3/4" for each foot of belt between the

pulley and sheave. (See illustration at right)

NOTE: Never adjust the belt tension by changing the

setting of the motor sheave. This setting was determined

to provide the correct blower speed for the given CFM

and system static pressure.

5. If ductwork has been installed and unusual static pressure is encountered, the pulley settings may

be changed, providing the blower ampere ratings are not exceeded as indicated on the unit

nameplate.

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

6

Tel: (800)-288-0892 • www.aresmakeupair.com

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

7

Tel: (800)-288-0892 • www.aresmakeupair.com

TROUBLE SHOOTING GUIDE

1. If unit is inoperative, check:

a. Circuit breakers

b. Line fuses

c. Voltage at starter

2. If

insufficient

cooling

occurs,

check:

a. Visually check pump operation.

b. Water system obstructions.

3. If

low

airflow

occurs,

check:

a. Blower belts slipping

b. Improper motor sheave setting

c. Evaporator or filter pads plugged up

d. Excessive ductwork resistance

e. Blower motor horsepower too low for requirements.

4. If there is mineral buildup on evaporative pads, check: (Evaporative only SE and DE)

a. Insufficient bleed off water

b. Bleed line plugged

c. Insufficient water over pads (hardness of water may necessitate more frequent cleaning

and/or pad replacement).

MAINTENANCE AND CLEANING FOR EVAPORATIVE

COOLING UNITS

WARNING:

Use care when working around live voltage, failure to do so may result in

severe injury or death for which ARES will not be responsible.

1. The reservoir pan should be drained and cleaned at least once every cooling season and before

every winter operation; clean pans more often if water conditions require it.

a. Remove the overflow standpipe and allow water to drain.

b. Clean out all sediment and if necessary, paint bare metal or scratches with protective paint

or undercoating.

c. Water distribution troughs must be unobstructed.

2. Inspect cooling filter media monthly for mineral deposits (in hard water areas, mineral salts will

build up quickly).

Be sure filter media is clean and does not obstruct airflow during winter operations.

3. The need for changing filter pads more frequently varies with locality, particularly areas where dust,

alkali and other foreign matter accumulate in the pads.

a. To change filter pads, use ARES filter pads #987360 Coolpad or O5915 Glacier-Cor

®

for

evaporative cooling.

b. Lay louvered panels on a flat surface with wire filter retainers face up.

c. Remove the center frame support and the filter retainers by pressing down on each end of

the retainers to disengage hooks from the holes in the pad frame.

d. Remove and discard used filter pads. Clean and paint all bare surfaces as needed. Check

slots in the water distribution trough to be sure that they are open and free of obstructions.

Evaporative units only (See illustration on next page top right).

e.

Install a new

fi

lter pad in the frame. Check that the pad is of uniform thickness

and completely

fi

lls the frame to avoid air bypass.

CAUTION:

Automatically Operated Device - To Reduce the Risk of Injury, Disconnect From Power

Supply Before Servicing.

f. Reinstall the wire filter retainer in the holes provided on the pad frame.

g. For evaporative cooling units, presoak the pads (already reassembled in the frame) with

water thoroughly for several minutes before reinstalling. This soaking conditions the surface

and the fibers of the pads, increasing water absorbability and filter performance in the

evaporative cooling process.

h. Correct belt adjustment is important as it cuts power consumption and prolongs the life of

the belt and motor.

i. When adjusting the belt tension, loosen the four motor mounting bolts and adjust the motor

until the belt can be deflected 1/2" to 3/4" for each foot of belt between the pulley and sheave.

WARNING:

Never tighten the belt by adjusting the motor sheave.

j. The blower motor, blower shaft bearings and recirculating pump on evaporative cooling units,

should be oiled twice a year with SAE 20 weight oil.

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

8

Tel: (800)-288-0892 • www.aresmakeupair.com

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

9

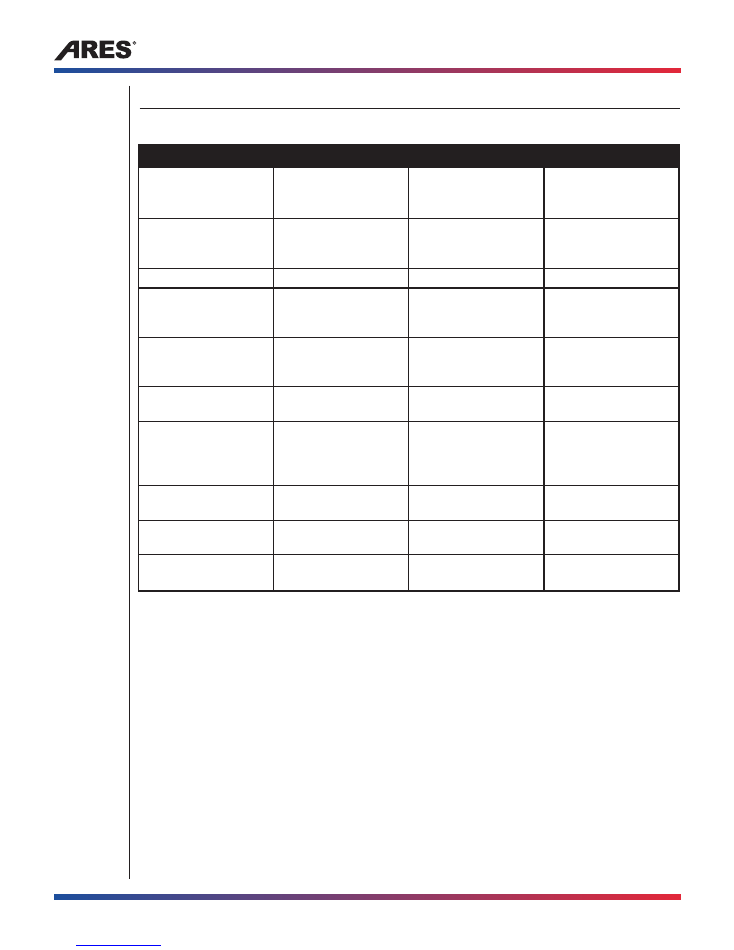

Preventative Maintenance Chart

MAINTENANCE ITEMS

QUARTERLY

HEATING SEASON

COOLING SEASON

STANDARD EVAPORATIVE COOLERS

Evap/filter media

Check and clean.

Check and clean.

Check and clean.

Replace if necessary.

Replace every 5 yrs.

Evap pump/basket

Clean before start

of season.

Check for operation.

Evaporator pan

Check and clean.

Drain and clean.

Clean and fill.

Float valve assembly

Check operation.

Turn off water supply.

Turn on water and

check for proper

adjustment, 2" in pan.

Bleed off valve

Check for clogging.

Assure proper

placement in drain

overflow pipe.

Belt adjustment

Check tension, wear

and adjustment.

Adjust as needed.

Adjust as needed.

Water distribution

manifold

Clean and flush.

Be sure to turn off

water supply & drain

water from system.

Clean & flush. Make

sure all distribution

points are free of any

obstructions.

Blower motor

Check amp draw, belt

tension & wear.

Check amp draw and

oil bearings.

Check amp draw &

oil bearings.

Drives, bearings

& pulleys

Check alignment &

bearing wear.

Check alignment &

bearing wear.

Check alignment &

bearing wear.

Fill & drain kits

Check corrosion

& leaks.

Ensure drain valve

opens, draining pan.

Ensure fill valve opens,

filling pan.

Tel: (800)-288-0892 • www.aresmakeupair.com

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

0

1

Tel: (800)-288-0892 • www.aresmakeupair.com

N

OTE:

IF

A

N

Y

OF

T

H

E

O

R

IGI

N

A

L

WI

R

E

AS

S

U

PP

LIE

D

WIT

H

T

H

E

APP

LIA

NC

E

M

U

ST

BE

R

EP

LA

C

E

D

, IT

M

U

ST

BE

R

EP

LA

C

E

D

WIT

H

WI

R

IN

G

MATE

R

IA

L

H

AVI

N

G

A

TEMPE

R

AT

URE

R

ATI

N

G

OF

AT

L

EAST

105

∞

C

.

FIELD

HI

VOL

T

FIELD

LO

VOL

T

FACTORY

LO

VOL

T

N

OTE:

IF

A

N

Y

OF

T

H

E

O

R

IGI

N

A

L

WI

R

E

AS

S

U

PP

LIE

D

WIT

H

T

H

E

APP

LIA

NC

E

M

U

ST

BE

R

EP

LA

C

E

D

, IT

M

U

ST

BE

R

EP

LA

C

E

D

WIT

H

WI

R

IN

G

MATE

R

IA

L

H

AVI

N

G

A

TEMPE

R

AT

URE

R

ATI

N

G

OF

AT

L

EAST

105

∞

C

.

FIELD

HI

VOL

T

FIELD

LO

VOL

T

FACTOR

Y

HI

VOL

T

FACTOR

Y

HI

VOL

T

FACTORY

LO

VOL

T

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

1

1

T

el: (800)-288-0892 • www.aresmakeupair.com

N

OTE:

IF

A

N

Y

OF

T

H

E

O

R

IGI

N

A

L

WI

R

E

AS

SUPPL

IED

WIT

H

T

HE

APPL

IANCE

MUS

T

BE

R

EP

LA

C

E

D

, IT

MU

ST

BE

R

EP

LA

C

E

D

WIT

H

WI

R

IN

G

MA

TER

IAL

HAV

IN

G

A

T

EMPERA

TURE

RA

TI

N

G

OF

A

T

LEAS

T

105

∞

C

.

FIELD

HI

VOL

T

FIELD

LO

VOL

T

FACTORY

LO

VOL

T

N

OTE:

IF

A

N

Y

OF

T

H

E

O

R

IGI

N

A

L

WI

R

E

AS

SUPPL

IED

WIT

H

T

HE

APPL

IANCE

MUS

T

BE

R

EP

LA

C

E

D

, IT

MU

ST

BE

R

EP

LA

C

E

D

WIT

H

WI

R

IN

G

MA

TER

IAL

HAV

IN

G

A

T

EMPERA

TURE

RA

TI

N

G

OF

A

T

LEAS

T

105

∞

C

.

FIELD

HI

VOL

T

FIELD

LO

VOL

T

FACTORY

LO

VOL

T

460V

to

120V

KVA

TR

A

N

SFO

R

ME

R

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

2

1

FACTOR

Y

HI

VOL

T

FACTOR

Y

HI

VOL

T

T

el: (800)-288-0892 • www.aresmakeupair.com

Parts List

PART NO. DESCRIPTION

O5195

2" Glacier-Cor Media Replacement Assembly

O7400

Pad Frame Assembly (includes Coolpad)

987060

Motor Base

990075

Pump CP6500

980390

Pump Basket

981665

Float Valve

987360

Coolpad Filter 36" X 34"

989635

Blower 15 X 15 Assembly

990715

Blower 18 X 18 Assembly

986400

1/2 HP 115/230V, 1 Phase, 1 Speed

986405

1/2 HP 208/230-460V, 3 Phase, 1 Speed

986420

1/2 HP 115/230V, 1 Phase, 1 Speed

986425

1/2 HP 208/230-460V, 3 Phase, 1 Speed

986450

1 HP 115/230V, 1 Phase, 1 Speed

986455

1 HP 208/230-460V, 3 Phase, 1 Speed

986490

1-1/2 HP 115/230V, 1 Phase, 1 Speed

986500

1-1/2 HP 208/230-460V, 3 Phase, 1 Speed

984520

2 HP 208/230-460V, 3 Phase, 1 Speed

986515

2 HP 115/230V, 1 Phase, 1 Speed

986540

3 HP 208/230-460V, 3 Phase, 1 Speed

986565

5 HP 208/230-460V, 3 Phase, 1 Speed

986570

7-1/2 HP 208/230-460V, 3 Phase, 1 Speed

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

3

1

Tel: (800)-288-0892 • www.aresmakeupair.com

Service and Ordering Information

1. ORDERING

For prompt and accurate handling of your order, always include: (See Owner’s Registration Reference

Sheet Page 16)

a. Serial number on unit part

b. Model number of unit

c. Part number

d. Part name

e. Voltage

f. Owner and property location

g. Date installed (See Owner Registration in the back of this manual)

Shipment may be delayed without proper information.

If unit is in warranty, replacement part will be billed and shipped. Credit will be issued when the part in

question is returned, inspected and found defective under normal usage (call the Service Department

at ARES

®

for instructions).

2.TERMS AND CONDITIONS

Price changes: All prices will be shipped C.O.D. for customers without an open account.

Returns: Written authority must be obtained before returning any merchandise. All returned

merchandise must be shipped prepaid and is subject to a handling charge.

Damaged merchandise: Notify the carrier in the event of damaged shipments, whether apparent at the

time of delivery or concealed damage is discovered after unpacking. File your complaint with the

carrier, not the factory. ARES’ responsibility ceases when shipment is accepted by a reliable carrier for

delivery.

Taxes: Any taxes or other government charge upon production, sale and/or shipment of merchandise

sold hereunder, not imposed by Federal, State, or Municipal authorities, or hereafter becoming

effective, shall be added to the price herein provided, and shall be paid by the buyer.

ALL SHIPMENTS F.O.B., Denison, TX

TO ORDER PARTS OR OBTAIN SERVICE INFORMATION,

OR A PRINTED COPY OF THIS

MANUAL,

CONTACT:

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

4

1

Tel: (800)-288-0892 • www.aresmakeupair.com

(800)-288-0892

3328 Interurban Road

Denison, TX 75020

Fax (903) 463-1235

Limited Warranty

Packaged Make-up Air and Blower Units

Model No. ___________________________ Serial No. ________________________________

Voltage _____________________________

Date Installation completed _________________

ARES extends this warranty to the original owner of this make-up air unit, providing it is installed

according to factory instructions, the warranty card is completely filled out and returned to the factory,

and the unit is used under normal conditions.

Length and Coverage of Warranty

The manufacturer will provide free replacement for any part which fails as a result of a defect in material or

workmanship during the first year after the date of installation (or 18 months from date of shipment; whichever

comes first). The cost of labor and transportation is not included in this offer.

Standard evaporative cooling stainless steel pans and optional unit casings have a 15 year no rust

through warranty.

Exemptions of Warranty Coverage

A. The manufacturer is not responsible for any damage caused by a defect in material or workmanship. This

includes, but is not limited to misuse, abuse, improper installation and transportation or handling damage.

B. Where applicable, the manufacturer is not responsible for any consequential damage resulting from any

malfunction.

C. The manufacturer is not responsible for the cost of labor and transportation that may be required to replace

the parts covered in Section 1 on this warranty.

D. This packaged make-up air unit must be installed outdoors only. Indoor installation, alterations, disassembly

of unit, or any rewiring other than factory recommended wiring voids this warranty.

E. “Rust Warranty” does NOT cover “White Rust” resulting from dried calcium deposit build up on cabinet parts,

or damage resulting from lack of regular, routine maintenance.

Obtaining Warranty Service

Please contact installing contractor, servicing contractor and/or the selling agency from whom you purchased the

unit. If you cannot locate them, contact ARES

®

, 3328 Interurban Road, Denison, TX 75020. Phone: (800)-288-0892;

fax: (903)-463-1235 or by email at info@aresmakeupair.com.

Any warranty that may be implied from this purchase is hereby limited to the one-year duration of this warranty.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply

to you.

What to do in case of unsatisfactory warranty service.

Please write the ARES

®

Service Department. Include your name, address and zip code, name of agency from

whom unit was purchased, the model and serial number of the unit, date of purchase and a description of the

problem.

Any warranty that may be implied from this purchase is hereby limited to the one year duration of this warranty.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may be apply

for you.

This warranty gives you specific legal rights, and you may also have rights which may vary from state to state.

Parts may be ordered from the ARES Service Dept. by contacting by phone at (800)-288-0892. You may also

contact us by fax at (903)-463-1235 or by email at info@aresmakeupair.com.

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

5

1

Tel: (800)-288-0892 • www.aresmakeupair.com

OWNER REGISTRATION

REFERENCE SHEET

For

Packaged Make-up Air Units

(fill out at time of installation)

DO NOT REMOVE FROM THIS MANUAL

Model No.__________________________ Serial No. _______________________

Customer’s Name____________________________________________________

Address____________________________________________________________

Installer’s Name _____________________________________________________

Address____________________________________________________________

Installed at _________________________________________________________

Installation Date _____________________________________________________

Remarks ___________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

Te

6

1

m

o

c

.r

i

a

s

r

a

m

.

w

w

w

:

t

e

n

r

e

t

n

I

•

6

6

2

1

-

1

2

4

)

0

0

8

(

:l

Tel: (800)-288-0892 • www.aresmakeupair.com

(800)-288-0892

3328 Interurban Road • Denison, TX 75020

Fax (903) 463-1235 • www.aresmakeupair.com • info@aresmakeupair.com

Make-up Air Blower Model SC1/SC2/SC3, SE1/SE2, DC1/DC2 and DE1/DE2

7

1

Warranty Registration

This sheet should be filled in and mailed to the factory within 15 days following

installation.

Owner: __________________________________________________________________________

Address:_________________________________________________________________________

Phone: __________________________________________________________________________

Installer: _________________________________________________________________________

Address:_________________________________________________________________________

Phone: __________________________________________________________________________

In Service Date: ___________________________________________________________________

SUPPLY

Model: ______________________________________________

Serial No.: ___________________________________________

Belt Size:____________________________________________

Drive Pulley Size: _____________________________________

Wheel Pulley Size: ____________________________________

Motor HP: ___________________________________________

Voltage: _____________________________________________

Phase:______________________________________________

Fuse Size: ___________________________________________

Overload Setting: _____________________________________

Motor Amps RTD: _____________________________________

Actual: ______________________________________________

_

_

_

_

_

_

_

o

N

_

_

_

_

_

_

s

e

Y

yl

r

e

p

o

r

p

d

e

n

g

il

a

s

tl

e

b

e

r

A

Are set screws and locking collars tight

Yes ______

No _______

_

_

_

_

_

_

_

o

N

_

_

_

_

_

_

s

e

Y

n

o

it

a

r

b

iv

r

o

t

n

e

m

n

g

il

a

l

e

e

h

w

l

a

u

s

u

n

U

_

_

_

_

_

_

_

o

N

_

_

_

_

_

_

s

e

Y

yl

r

e

p

o

r

p

g

n

ik

r

o

w

r

e

g

n

a

h

c

x

e

t

a

e

h

s

I

_

_

_

_

_

_

_

o

N

_

_

_

_

_

_

s

e

Y

yl

r

e

p

o

r

p

g

n

ik

r

o

w

s

d

a

p

.

p

a

v

E

e

r

A

_

_

_

_

_

_

_

o

N

_

_

_

_

_

_

s

e

Y

d

e

ll

a

t

s

n

i

yl

r

e

p

o

r

p

s

e

s

a

b

t

i

n

u

e

r

A

System operational without further adjustment

Yes ______

No _______

System requires following corrections:__________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

y

b

d

e

t

c

e

p

s

n

i

m

e

t

s

y

S

o

t

d

e

t

a

rt

s

n

o

m

e

d

m

e

t

s

y

S

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

T

el: (800)-288-0892 • www.aresmakeupair.com

Place

Postage

Here

ARES

3328 Interurban Road

Denison, TX 75020

ATTN: WARRANTY DEPT