Full Text Searchable PDF User Manual

www.Gatemotors.com

Support@Gatemotors.com

Tel:305-809-6301

Lockmaster DKC400UY

Lockmaster DKC400U

Aleko AR-1450

ALEKO AR1450 SLIDING GATE OPERATOR USER’S MANUAL

1

OUTLINE

1. Important safety information

…………………………

3

2. Main features

………………………………………

3

3. Main technical parameters

…………………………

3

4. Working principle and main structure

………………

4

5. Installation and adjustment

…………………………

4

6. Connecting

…………………………………………

7

7. Control

……………………………………………

10

8. Check

……………………………………………

14

9. Maintenance

………………………………………

14

10. Troubleshooting

…………………………………

15

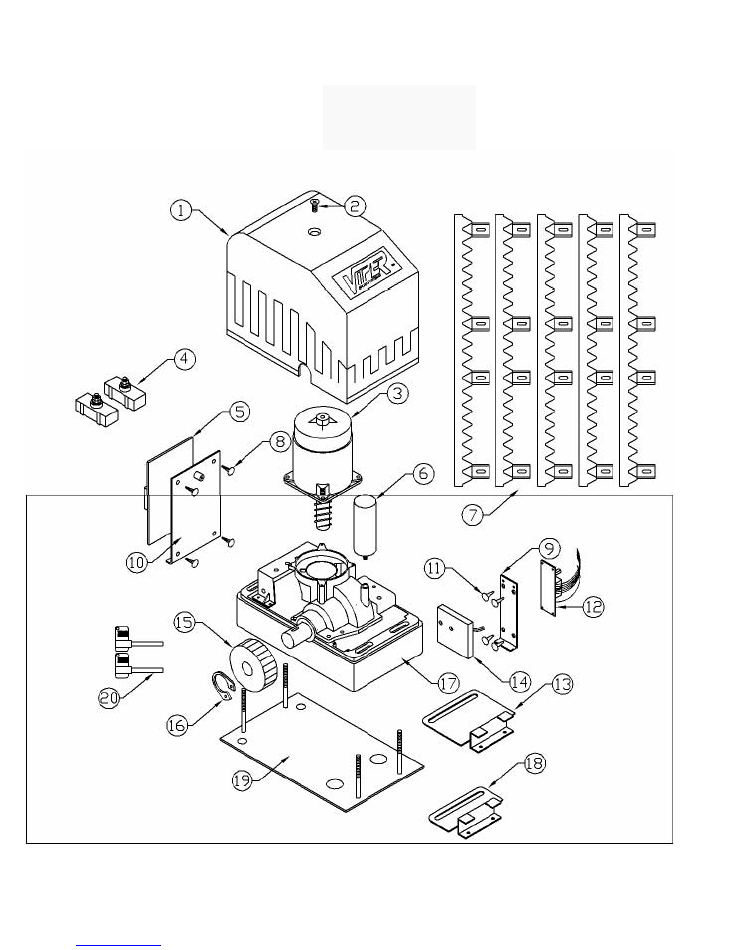

AR-1450

2

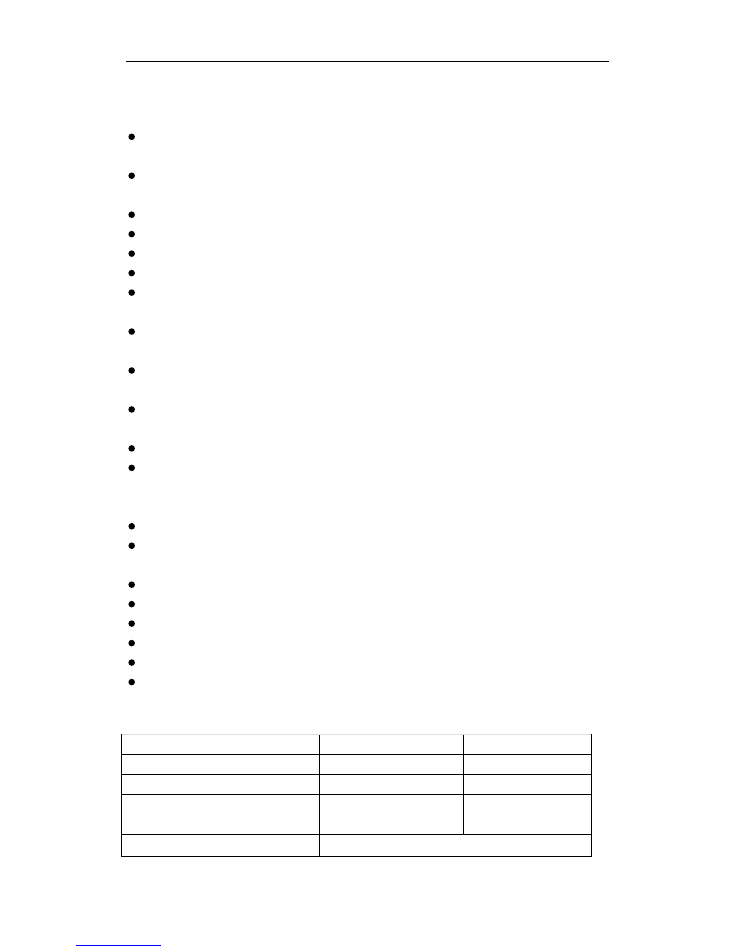

MODEL

:

AR-1450

COMPONENT

DESCRIPTION

COMPONENT

MANUFACTURER

MFR’S PART NO.

QUANTITY

1

Cover

ALEKO

tr3cov1

1

2

Set Phillips screw

ALEKO

tr3sps2

1

3

½ h.p. Motor

ALEKO

tr3mot3

1

4

Limit magnets

ALEKO

tr3lm4

2

5

Control board

ALEKO

tr3c/b5

1

6

Capacitor

ALEKO

tr3cap6

1

7

Gear racks 2.3 ft.

ALEKO

tr3gr7

5

8

Plastic clip

ALEKO

tr3pc8

4

9

Base plate for receiver/

limit switch sensor

ALEKO

tr3bp9

1

10

Base plate for control board

ALEKO

tr3bp10

1

11

Plastic clip

ALEKO

tr3pc11

4

12

Receiver

ALEKO

tr3rec12

1

13

Large bracket for magnet (open limit)

ALEKO

tr3lbol13

1

14

Limit switch sensor

ALEKO

tr3ls14

1

15

19 tooth Sprocket

ALEKO

tr319spr15

1

16

C-Clamp

ALEKO

tr3ccl16

1

17

Motor housing

ALEKO

tr3mh17

1

18

Small bracket for magnet (close limit)

ALEKO

tr3sbcl18

1

19

Mounting base

ALEKO

tr3mb19

1

20

Manual release keys

ALEKO

tr3keys20

2

3

Residential Sliding Gate

Operator

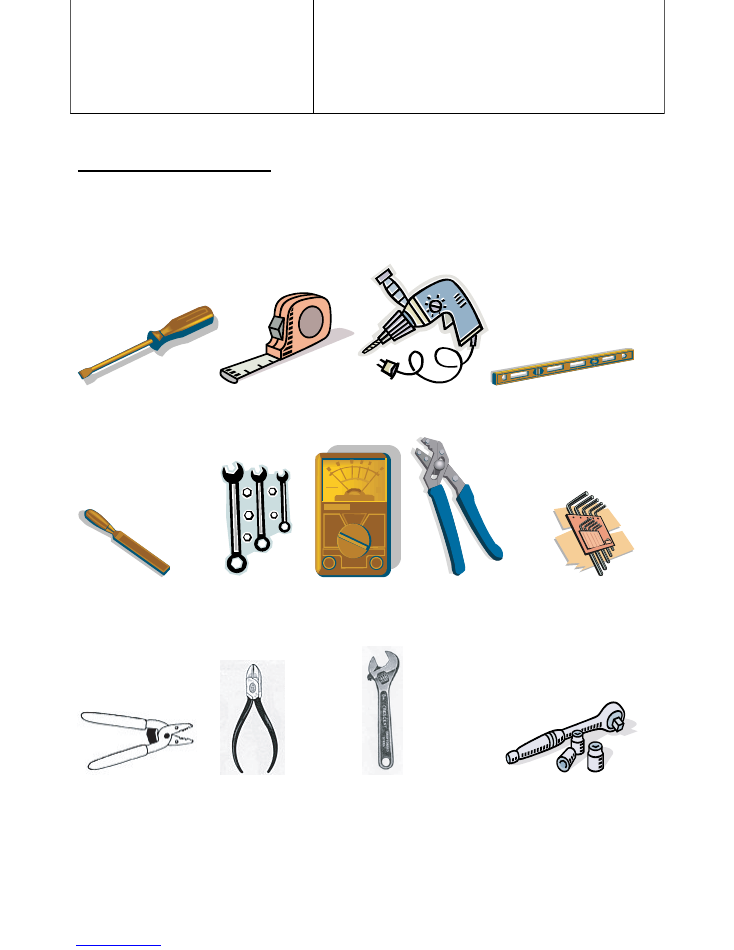

Tools you will need

During assembly and installation of your opener, the instructions will call for the use of

various tools shown below. Other tools may be required as needed for the installation of

the concrete pad and electrical connection.

Table 3 Required Tools for Installation

Screwdriver

Tape Measure

Electric Drill

Level

File

Wrenches

Multimeter

Pliers

Allen Wrenches

Wire Strippers

Wire Cutter

Adjustable Wrench

Socket Wrench

4

AR-1450

ALEKO AR-1450 SLIDING GATE OPERATOR USER’S MANUAL

5

1. Important safety information

Carefully read and follow all safety precaution and warnings before attempting to install and use

this operator, incorrect installation can lead to severe injury.

The gate operator should be installed by a qualified technician; otherwise, serious personal

injury or property damage may occur.

The auto-reverse function must be checked during installation to ensure that the gate can

auto-reverse in the event of obstruction.

This auto-reverse function should be regularly inspected and adjusted, if necessary.

When opening or closing the gate, do not attempt to walk or drive through the gate.

Children should not be allowed to play near or operate automatic gates.

The automatic gate operator must be grounded.

Install the gate operator on the inside of the property, DO NOT install it on the outside of

the property where the public has access to it.

Be careful when in close proximity to moving parts where hands or fingers could be

pinched.

Do not allow control devices to be placed so that a person can access them by reaching

through the gate.

In the event of power failure, an emergency release key allows you to operate the gate

manually.

The operator should be switched off before repairing it or opening its cover.

Please erase and reprogram the code after installing the operator.

2. Main features

The device is used to drive sliding gate.

For your safety, the AR-1450 will stop and

reverse if it was obstructed on closing and

stop when it was obstructed on opening.

Supports up to 100 remote controls.

User programmable and user erasable remote codes.

Infrared terminal (N.C) is supplied to use.

Auto-close feature is available for this operator.

Pedestrian mode.

Manual key release design for emergency purposes.

3. Main technical parameters

e

p

y

T

Power supply:

AC 220V, 50Hz

AC110V, 60Hz

Motor speed

1400 r/min

1680 r/min

Gate moving speed

14m/min (24 teeth)

11m/min (19 teeth)

17 m/min (24 teeth)

13m/min (19 teeth)

Output torque

14N

·

m

AR-1450

AR-1450

ALEKO AR-1450 SLIDING GATE OPERATOR USER’S MANUAL

6

4. Working principle and main structure

The device is composed of a single-phase motor, worm and worm gear. The main shaft of the

motor rotates the worm with the clutch engaged, the worm rotates the worm gear and output

gear, which pushes the rack attached to the sliding gate, thus moving the gate.

The device is installed with a thermal protector, the thermal protector will switch off the motor

automatically in case of the temperature is higher than 120°C and switch on the motor

automatically when the temperature is lower than 85°C

±

5°C.

5. Installation and adjustment

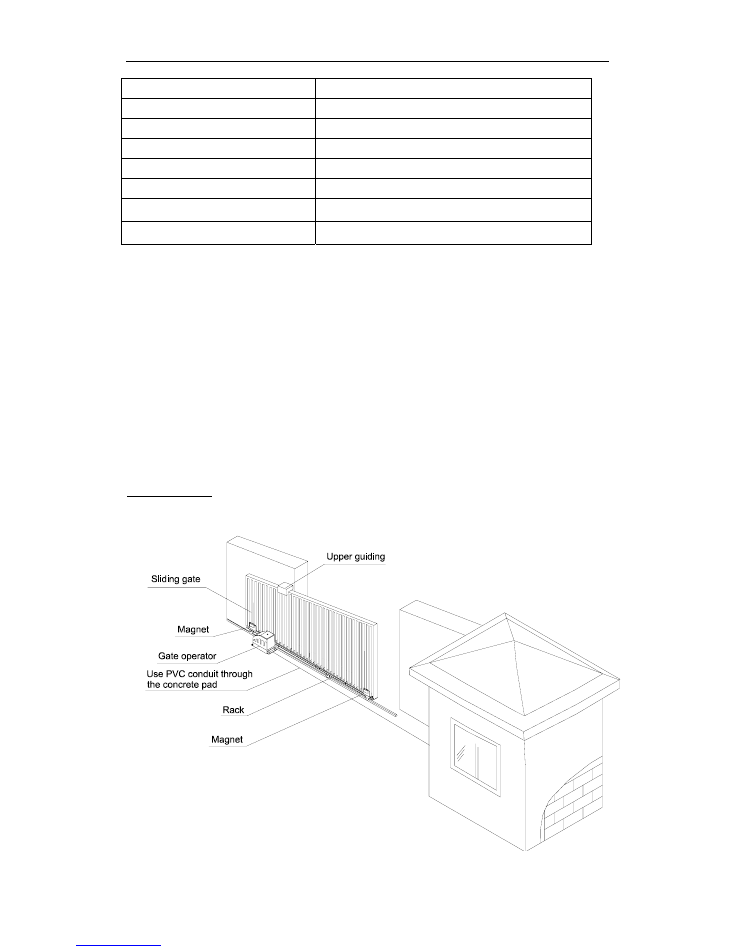

The AR-1450 rack-driven gate operator operates

by forcing a drive rack past a drive gear.

The entire configuration is shown in Fig.1. The gate operator must be installed on the inside of

the gate.

Gate preparation

Be sure the gate is properly installed and slides smoothly before installing the AR-1450

sliding gate operator. The gate must be plumb, level, and move freely.

Fig.1

Limit switch

Magnetic limit switch

Remote control operating range

30m

z

H

m

2

9

.

3

3

4

y

c

n

e

u

q

e

r

F

Remote control mode

Single-button

Auto-close time

0-44 sec.

Working time

90 sec.

Noise

≤

62dB

Environmental temperature

-10

º

C~+55

º

C

ALEKO AR-1450 SLIDING GATE OPERATOR USER’S MANUAL

7

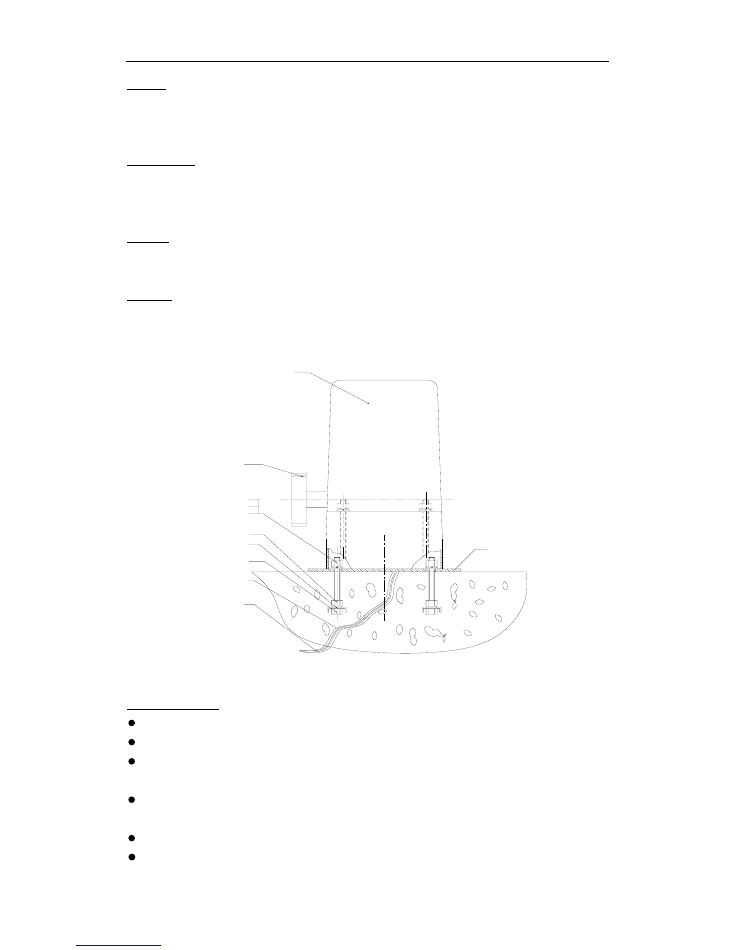

Conduit

In order to protect the wires, use PVC conduit for control wires, conduit must be set into the

concrete when it is poured. Wires within the conduit shall be located or protected so that no

damage can result from contact with any rough or sharp part.

Concrete pad

The base unit of the gate operator requires a concrete pad in order to maintain proper stability.

The concrete pad should be approximately 300mm x 200mm x 200mm deep in order to provide

for adequate operation.

Anchors

You can use the anchors, bolts, washers and nuts that are provided with the operator. These

anchors must be set into the concrete when it is poured, or you can use wedge anchors.

Operator

In locations where ground freeze is possible, mount the gate operator on installation pad as

shown in Fig.2. Check the operator and make sure it is lined up with the gate.

Nut

Bolt

Anchor

Nut

Spring washer

Plain washer

Gear

Gate operator

Installation pad

Conduit

Wires

Fig.2

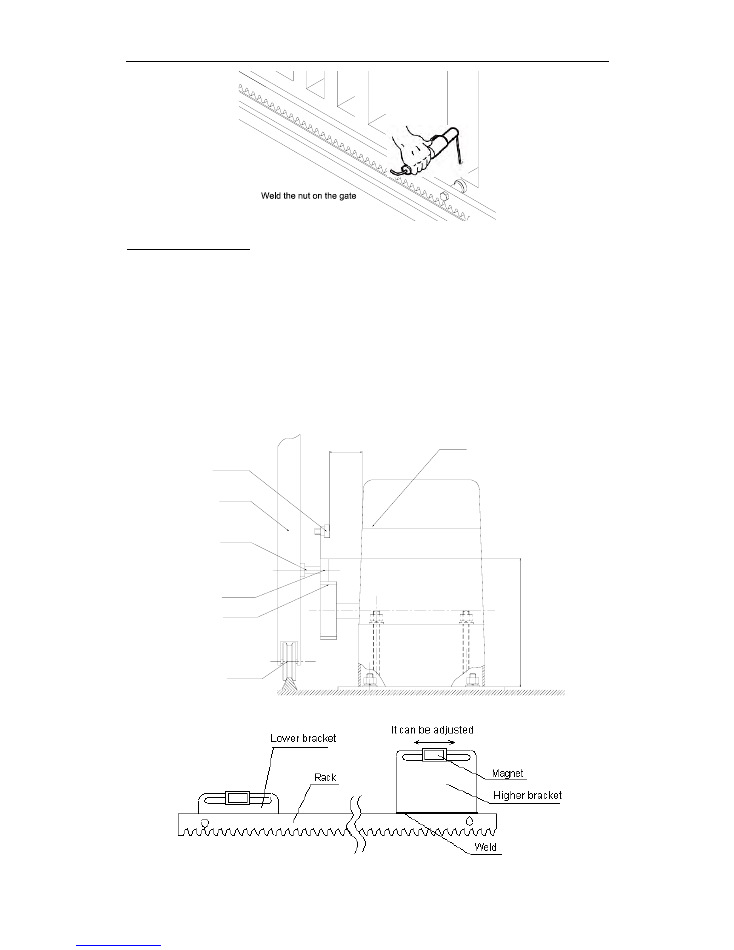

Installation of rack (see Fig.3)

Fix the three nuts (in the same package with rack) on the rack element.

Lay the first piece of rack on the gear and weld the first nut on the gate.

Move the gate manually, checking if the rack is resting on the gear, and weld the second

and third nut.

Bring another rack element near to the previous one. Move the gate manually and weld the

three nuts as the first rack, thus proceeding until the gate is fully covered.

When the rack has been installed, to ensure it meshes correctly with the gear.

The space between rack and gear is about 1mm.

﹡

If you have installed an external

button switch, you must use two

conduits: one for main power wire,

another one for low voltage wire

(button switch).

ALEKO AR-1450 SLIDING GATE OPERATOR USER’S MANUAL

8

Fig.3

Magnets for limit switch

To ensure safety, it is recommended to install limit devices at both ends of the gate to prevent

the gate from sliding out of the rails. The rails must be installed horizontally.

Install the magnet as shown in Fig.4 and Fig.5. The magnet and limit switch are used to control

the position of the gate.

Release the gear clutch and push the sliding gate manually to pre-determine the position.

Solder the magnet bracket to the rack and then tighten the gear clutch. The lower bracket is for

open position and higher bracket is for close position. Fix the magnet to the bracket. Adjust the

position of gate operator, the magnet should be 10~15mm away from the magnetic limit switch,

if too far away, the switch will fail to work. Moving the gate electrically, adjust the magnet to the

proper position until the position of the opening and closing meet the requirement.

10-15

mm

Magnet

Gate

Nut

Rack

Gear

Guide rail

122mm

Magnetic limit

switch inside

Fig.4

Fig.5

9

Setting of

the Control

Board

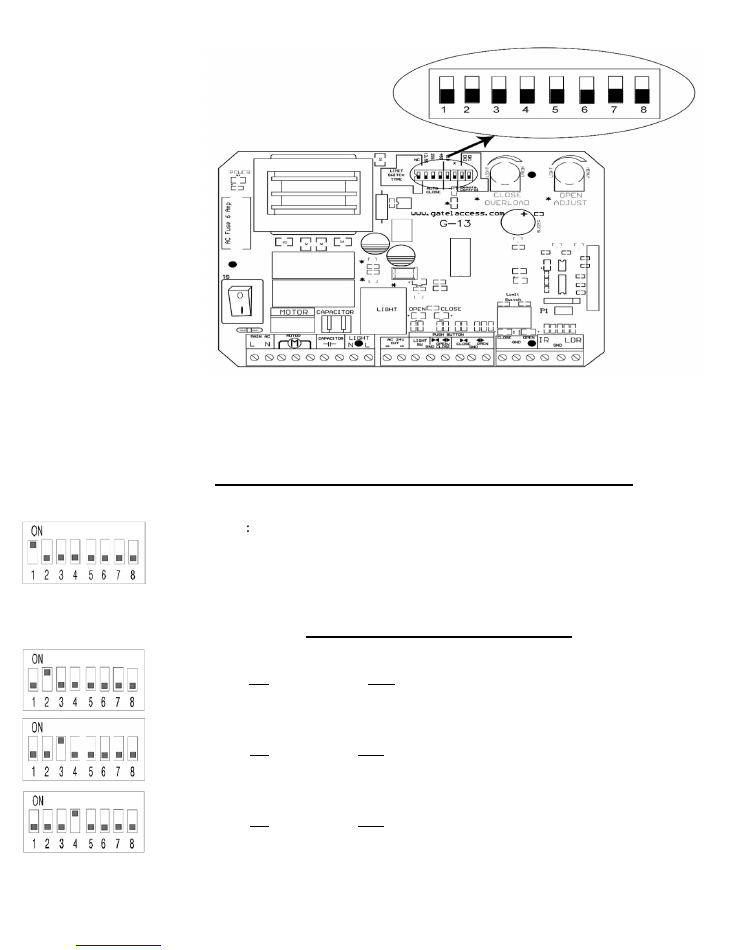

1. DIP Switches

The DIP switches are

used to set the limit

switch of the opener to

be NO or NC, auto close

time of the gate opener

and fast change the

open/close direction

which is determined by

the position of the gate

opener installed.

Setting of the Control Board

DIP Switch #1

:

Limit switch NC (

normally closed

) or NO (

normally open

)

DIP Switch #1

:

ON – NO / OFF –NC

This mode enables user to set the board to work with motor with NC or NO limit switch

NOTE: Factory default setting is NO

DIP Switch #2–#4: Auto close time of the gate opener

DIP Switch #2:

ON – 12.5 Seconds OFF – 0 Seconds

DIP Switch #3:

ON – 25 Seconds OFF – 0 Seconds

DIP Switch #4:

ON – 45 Seconds OFF – 0 Seconds

NOTE: The auto-close function would be disabled if all 3 dip switches are turned to off (factory default

setting).

10

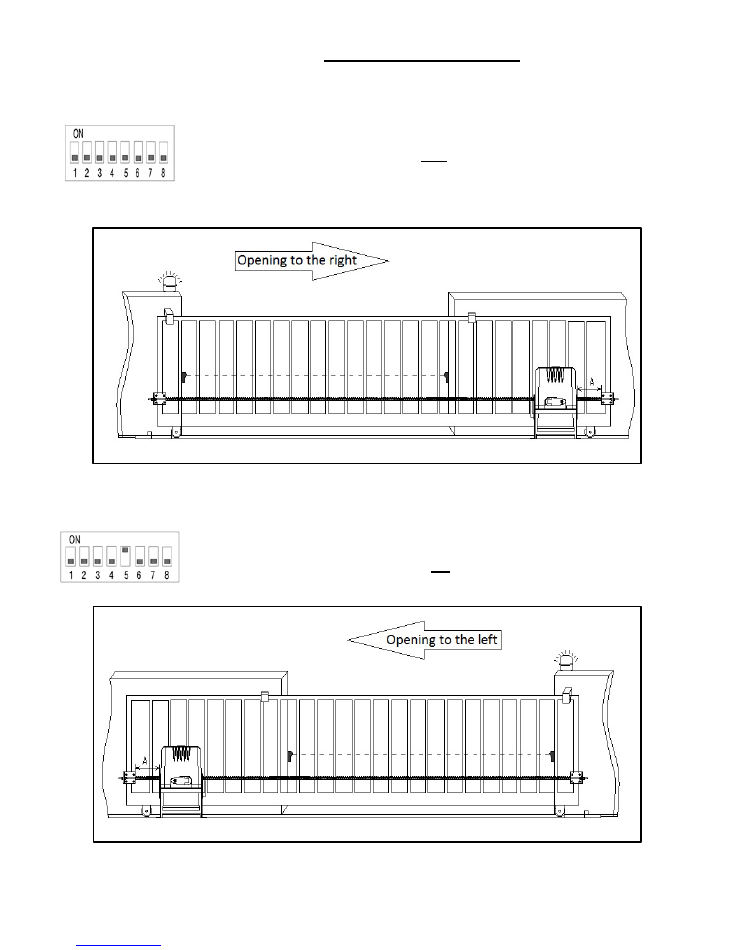

DIP Switch #5: Direction of gate opening.*

(*

Direc

ti

on from the inside of the property where the opener is installed.)

DIP Switch #5: OFF

– Opens to the right.

DIP Switch #5: ON –

Opens to the left.

Note: If opening is to the left, the Limit Switch wires on the control board (yellow & red) need to

be reversed. The black wire stays the same.

11

DIP Switch #6: (NOT USED)

DIP Switch #7–#8: Remote Control Button (yellow & blue) Setting

DIP Switch #7: ON

– Yellow Button is Working

OFF

– Yellow Button is Not Working

DIP Switch #8: ON

– Blue Button is Working

OFF

–Blue Button is Not Working

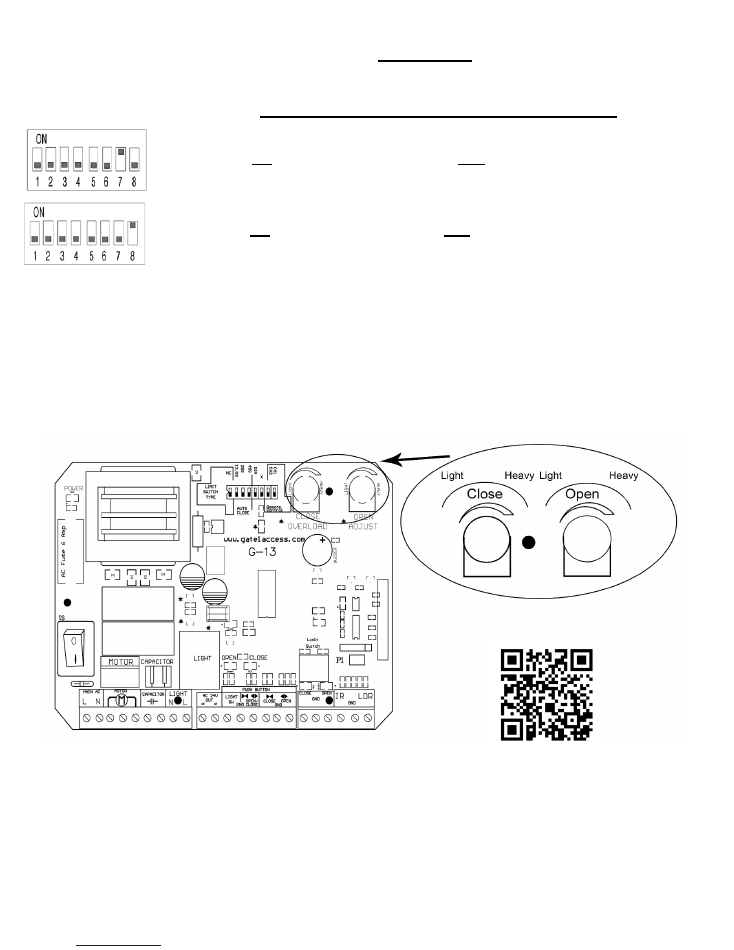

2. Potentiometers

The left potentiometer is to adjust the

CLOSE

stall force of the gate opener. The right Potentiometer is used to

adjust the

OPEN

stall force of the gate opener.

Turn the potentiometer clockwise to increase the stall force.

Turn the potentiometer counter-clockwise to decrease the stall force.

12

Test the reversing sensitivity

For the sake of safety, it is very important to test the reversing sensitivity as soon as the control board set is

finished.

The reversing sensitivity adjustment is inverse correlation with stall force adjustment in

potentiometer 1 and

potentiometer 2

. In other word, the stall force level is higher; the reversing sensitivity level is lower.

Put an immobile object along the gate path, and then operate the gate to strike it during the open and close

cycles. The gate must reverse as soon as object is struck with it. If the gate doesn’t reverse, please increase

the reversing sensitivity by turning the potentiometer in counter-clockwise direction. (Turning the stall force

potentiometer toward to “Light” position to increase the reversing sensitivity)

Note 1: If the sensitivity setting is too higher, the gate will stop or reverses very easy by itself

while there is little obstruction or resistance such as strong wind or heavy snow sometimes.

Note 2: Always check the gate reversing function every each time of control board set or

restart after power off.

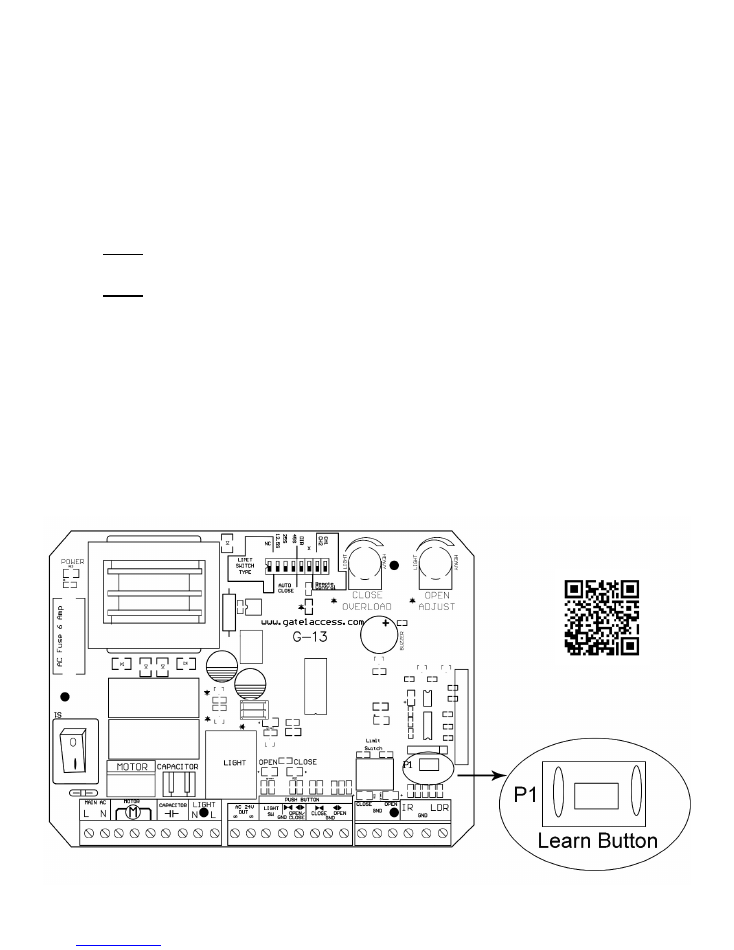

How to learn or erase the remote

Learn the remote

Press and release the learn button, the

BLUE LED

light will be on, then press any button in the remote within

5 seconds, the

BLUE LED

light will go off. Now the remote has been learnt successfully.

Erase all the remote codes

Press and hold the learn button until the

BLUE LED l

ight goes off after flashing 5 times. Now all remote codes have

been erased.

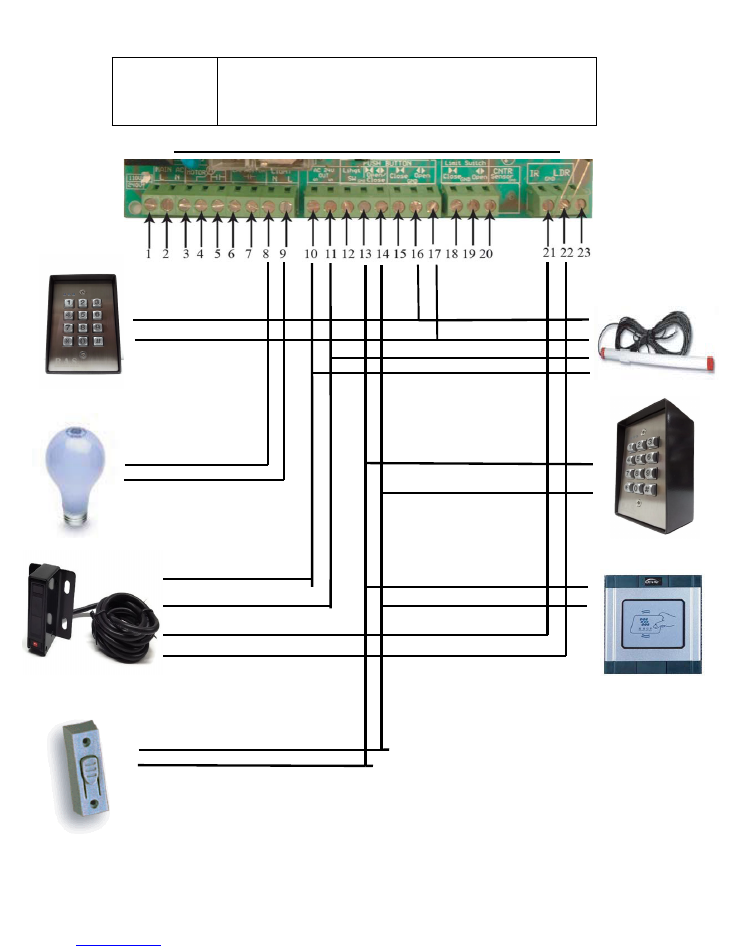

Residential Sliding Gate Operator

AR1450

Optional Equipment Installation Procedures

O

O

O

O

O

O

O

O

O

O

O

O

Blue

Brown

Black

White

Green

Brown

Red

Black

13

ALEKO AR1450 SLIDING GATE OPENER

14

11. Trouble Shooting

S

The wire connector terminal block

becomes loose.

Check wire connector terminal block make

sure it is plugged in terminal block 10 (X8).

The limit switch wire connector terminal

block becomes loose.

Check limit switch wire connector terminal

block make sure it is plugged in terminal

block 9 (X9).

Check the limit switch mode.

Motor only runs in one direction.

The electric component on the control

board such as Q2, Q91 or Q92 may be

damaged.

Replace the electric component Q2, Q91 or

Q92 (BTA16/600) or replace the board.

By pressing button 1(button 2 or button 3)

which has been programmed to open the

gate, press the same button again to stop

the gate in required position, but the gate

will auto-close immediately.

The auto-close time is too short.

Reset the auto-close time. See

Set auto-

close function

section.

When you use button 4 of remote control

to open the gate, gate travels too short.

The width of pedestrian mode is too

narrow.

Reset the width of pedestrian mode. See

Set

width of pedestrian mode

section.

When you use button 4 of remote control

to open the gate, but the gate will auto-

close immediately.

The auto-close time of pedestrian mode

is too short.

Reset the auto-close time of pedestrian. See

Set auto-close function of pedestrian

mode

section.

The limit switch wire connector terminal

block becomes loose.

Check the limit switch mode (see table 1 DIP

switch).

Connecting wires or terminal blocks are

too loose.

Check the connecting wires and terminal

blocks.

The electric component on the control

board such as Q2, Q91 or Q92 may be

damaged.

Replace the electric component Q2, Q91 or

Q92 (BTA16/600) or replace the board.

The gate will not open or close.

c t

The indicator light of remote control does

not light.

Check the batteries on your remote control.

Remote control is not suitable for

receiver.

After making sure the codes are correct,

erase remote controls and then re-program

the codes in the device. See

Adding extra

remote controls (learning)

section.

Remote control does not work

Broken receive board

Replace receive board.

The Force Adj. (VR1) is adjusted too

small.

Check the Force Adj. (VR1). Adjust VR1 to

increase force.

When you open the gate by using button

1(button 2 or button 3) which has been

programmed, gate will stop in mid-travel

or reverse before reaching the fully limit

position.

o

The remote control operating distance is

too short.

Signals are shielded by the gate.

Link a new antenna (1~1.2m BVR 0.75mm

2

see parts list) to the old antenna. Then fix the

antenna on the wall vertically, make sure the

total height from the top of antenna to the

ground is approx. 1.5m.

The gate opens, but stops and will not

return.

1. Please note the two magnet brackets

(fixed plate) are different: one is higher

and another is lower. Please try to

exchange the two brackets position.

2. Please try to exchange the limit switch

wires CL (close) and OP (open).

There are two reed switches inside the

magnetic limit switch: one is upper and

another is lower. Maybe the magnet position

was installed in the middle so it inducts both

reed switches. Solution: adjust the magnet

upper or lower.

Gate1Access LLC.

P.O. box 121776

Clermont Fl. 34712

sales@Gatemotors.com

www.Gatemotors.com

2011-2012 Aleko & Lockmaster All Rights Reserved