Full Text Searchable PDF User Manual

ART 22

DZR Balancing Valve

Flow Data

and

Installation Instructions

This datasheet is designed as a guide and should not be regarded as wholly accurate in every detail.We reserve the right to amend the

specification of any product without notice.

V1

ART 22

Technical Data

The Albion ART 22 is a fixed orifice double regulating valve used to regulate and

measure the flow passing through it.

Flow Coefficient

The flow rate can be calculated using the Kv value and a measured signal.

Kv = Q*36

Kvs = Q*36

√ ∆P

√ ∆Ps

where Kv &Kvs = flow coefficient (m3/hr at 1 bar differential)

Q = flow rate (l/s)

∆P = headloss attributable to valve (kPa)

∆Ps = differential pressure across tappings (signal) (kPa)

Kvs Values

Size ½”L ½”ML

½” ¾” 1” 1¼”

1½” 2”

Kvs 0.62 1.1

2.3

5.3 9.2 19.0 22.1 42.3

Pressure Loss

The pressure loss across the fixed orifice double regulating valve is the combined

loss attributable to the orifice plated and double regulating valve in the fully open

position.

Kv Values

Size ½”L ½”ML

½” ¾” 1” 1¼”

1½” 2”

Kv

0.533 0.738

2.00 3.88 7.28 13.39 18.69 30.10

Installation

Fixed orifice double regulating valves must always be installed with a minimum of

5 pipe diameters of straight pipe, without intrusion, upstream of the orifice plate.

Downstream of the valve a minimum of 2 pipe diameters of straight pipe are

required.

Sizing

Once the required flow rate has been calculated, the size of the fixed orifice

double regulating valve can be determined based on the following:

The minimum signal at the design flow rate of 1 kPa.

For minimum pressure loss, a maximum signal of 4.7 kPa, which corresponds

to the maximum differential pressure range of a fluorocarbon manometer.

V1

ART 22

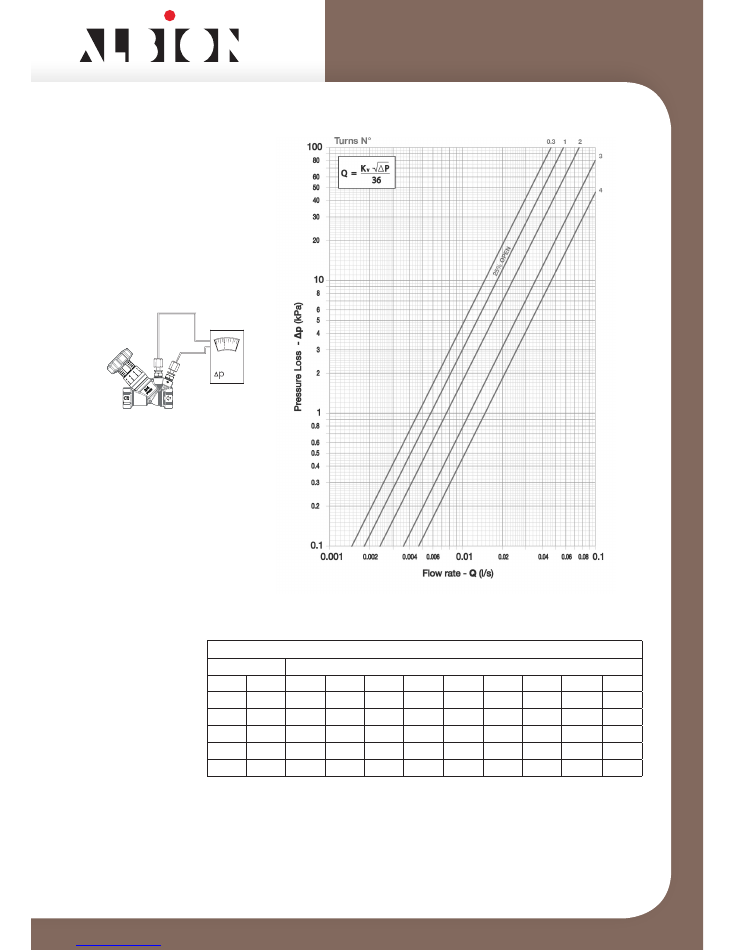

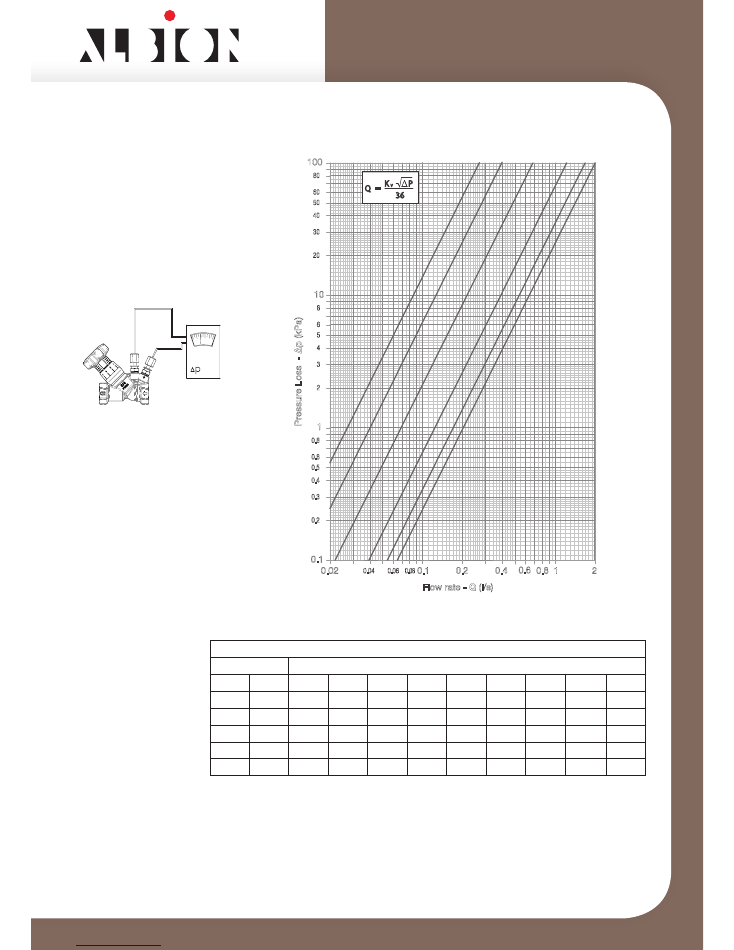

Kvs=0.62

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

0.165

0.173

0.180

0.186

0.191

0.196

0.200

1

0.204

0.209

0.213

0.218

0.223

0.229

0.236

0.243

0.251

0.260

2

0.270

0.281

0.293

0.305

0.318

0.332

0.347

0.362

0.378

0.394

3

0.410

0.426

0.442

0.457

0.472

0.486

0.499

0.510

0.520

0.528

4

0.533

V1

Kv Values - DN 15L

ART 22

ART 22

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

0.154

0.166

0.175

0.183

0.189

0.193

0.198

1

0.201

0.205

0.209

0.213

0.219

0.225

0.232

0.240

0.250

0.261

2

0.274

0.288

0.304

0.322

0.341

0.362

0.384

0.407

0.432

0.458

3

0.484

0.512

0.539

0.567

0.595

0.622

0.648

0.673

0.697

0.718

4

0.738

V1

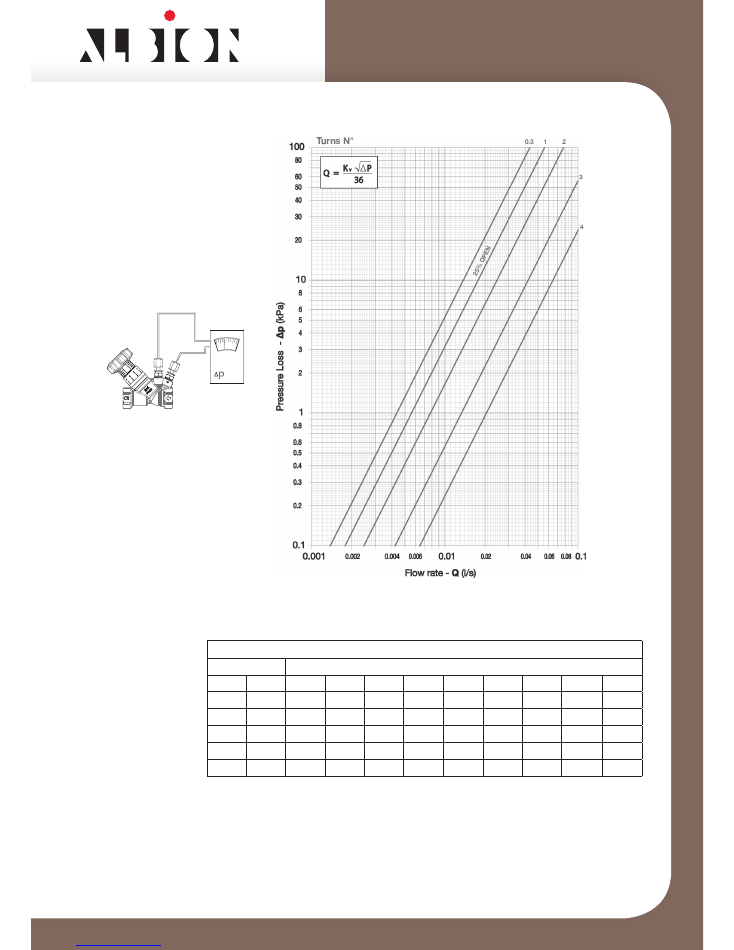

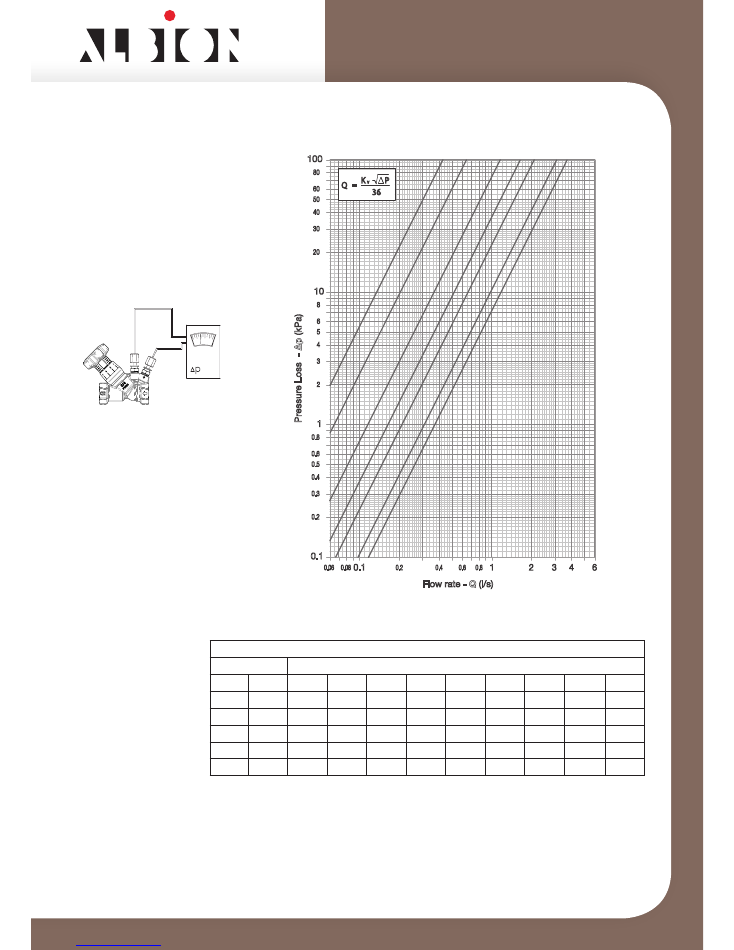

Kvs=1.1

Kv Values - DN 15ML

ART 22

ART 22

V1

Kv Values - DN 15

ART 22

Kvs=2.3

36

P

V

K

=

Q

0.08

0.8

0.6

0.4

0.2

0.04

0.02

0.06

20

30

40

50

60

80

0.2

0.3

0.4

0.5

0.6

0.8

8

6

5

4

3

2

0.01

0.1

1

0.1

Pr

essur

e Loss -

∆p

(kPa)

1

10

100

Flow rate -

Q

(l/s)

Turns N°

4

2

1

0.3

0.5

1.5

25% OPEN

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

0.47

0.68

0.83

0.98

1.10

1.20

1.29

1

1.37

1.44

1.50

1.55

1.61

1.64

1.67

1.69

1.71

1.72

2

1.73

1.74

1.74

1.76

1.78

1.81

1.84

1.86

1.88

1.89

3

1.90

1.92

1.93

1.95

1.97

1.98

1.98

1.99

2.00

2.00

4

2.00

ART 22

V1

Kv Values - DN 20

ART 22

Kvs=5.3

36

P

V

K

=

Q

0.08

0.06

0.04

20

30

40

50

60

80

0.2

0.3

0.4

0.5

0.6

0.8

8

6

5

4

3

2

0.02

0.1

1

0.1

Pr

essur

e Loss -

∆p

(kPa)

2

10

100

Flow rate -

Q

(l/s)

0.2

0.4

0.6 0.8 1

Turns N°

4.0

25% OPEN

3.0

2.0

1.0

0.3

1.5

0.5

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

0.54

0.73

0.89

1.04

1.16

1.30

1.42

1

1.54

1.64

1.74

1.84

1.93

2.03

2.10

2.17

2.26

2.31

2

2.37

2.42

2.48

2.53

2.58

2.63

2.71

2.82

2.96

3.04

3

3.17

3.31

3.44

3.54

3.64

3.70

3.76

3.80

3.82

3.83

4

3.88

ART 22

V1

Kv Values - DN 25

ART 22

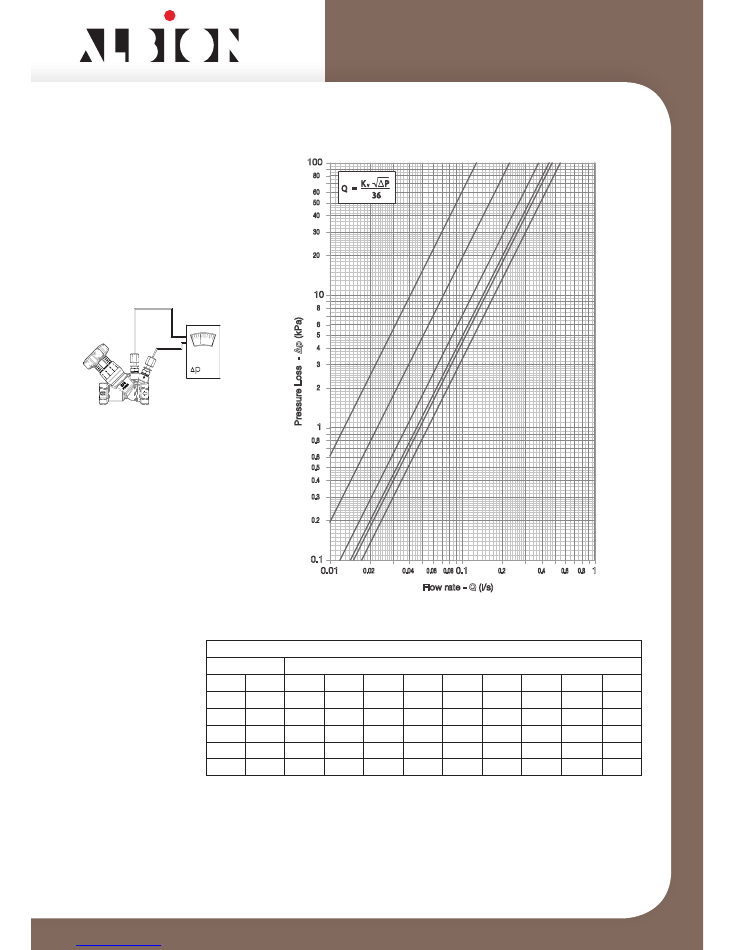

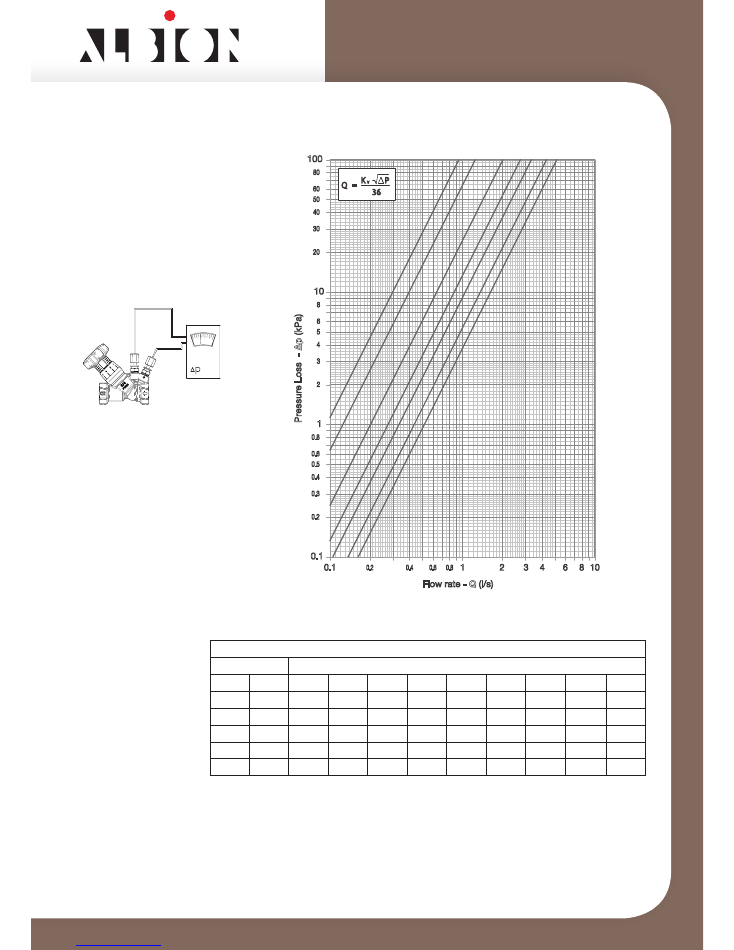

Kvs=9.2

36

P

V

K

=

Q

0.08

0.06

0.04

20

30

40

50

60

80

0.2

0.3

0.4

0.5

0.6

0.8

8

6

5

4

3

2

0.02

0.1

1

0.1

Pr

essur

e Loss -

∆p

(kPa)

2

10

100

Flow rate -

Q

(l/s)

0.2

0.4

0.6 0.8 1

Turns N°

4.0

25% OPEN

2.0

3.0

1.0

0.3

0.5

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

0.96

1.21

1.45

1.65

1.84

2.04

2.25

1

2.46

2.66

2.87

3.09

3.32

3.54

3.74

3.91

4.10

4.24

2

4.43

4.59

4.78

4.98

5.17

5.34

5.51

5.67

5.82

5.98

3

6.09

6.24

6.38

6.51

6.65

6.79

6.89

6.99

7.08

7.19

4

7.28

ART 22

V1

Kv Values - DN 32

ART 22

Kvs=19.0

36

P

V

K

=

Q

0.08

0.8

0.6

0.4

0.2

0.06

20

30

40

50

60

80

0.2

0.3

0.4

0.5

0.6

0.8

8

6

5

4

3

2

0.1

1

0.1

Pr

essur

e Loss -

∆p

(kPa)

1

10

100

Flow rate -

Q

(l/s)

2

3

4

6

Turns N°

4.0

3.0

2.0

1.0

25% OPEN

0.3

1.5

0.5

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

1.56

1.96

2.34

2.68

3.04

3.40

3.80

1

4.15

4.51

4.85

5.18

5.55

5.89

6.21

6.52

6.91

7.21

2

7.56

7.86

8.17

8.50

8.92

9.30

9.68

10.06

10.42

10.89

3

11.27

11.62

11.98

12.37

12.70

12.93

13.06

13.19

13.27

13.33

4

13.39

ART 22

V1

Kv Values - DN 40

ART 22

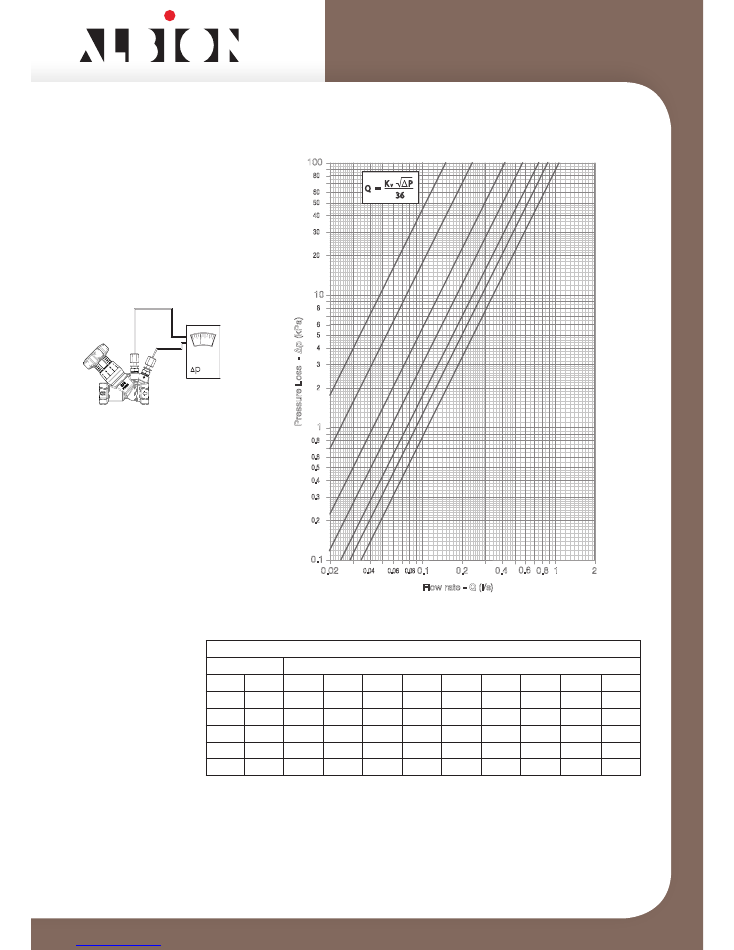

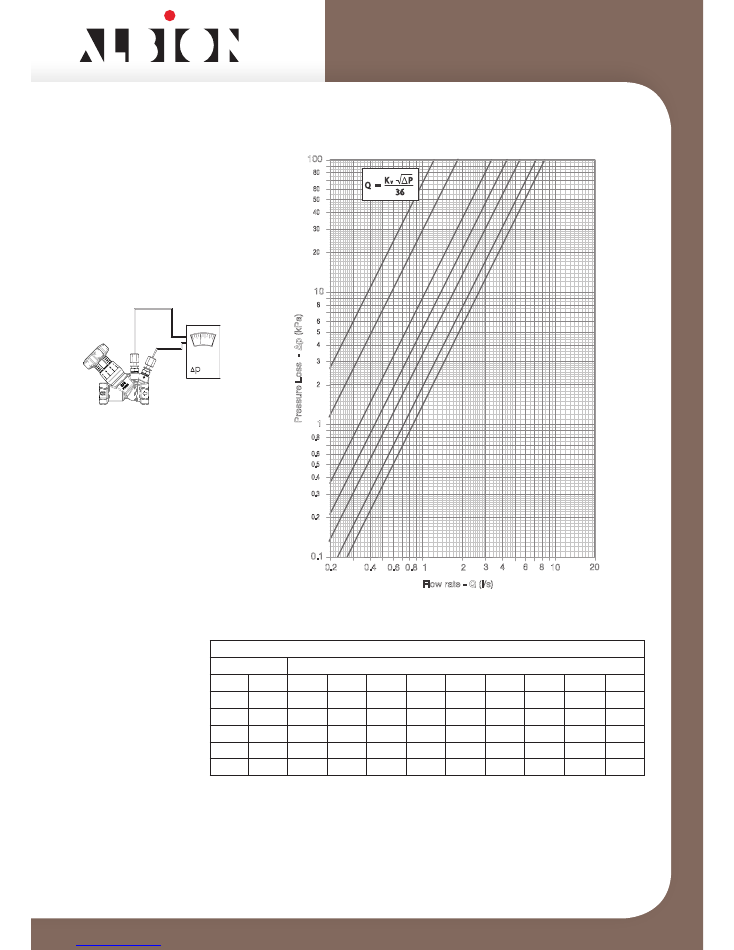

Kvs=22.1

36

P

V

K

=

Q

0.8

0.6

0.4

0.2

20

30

40

50

60

80

0.2

0.3

0.4

0.5

0.6

0.8

8

6

5

4

3

2

0.1

1

0.1

Pr

essur

e Loss -

∆p

(kPa)

1

10

100

Flow rate -

Q

(l/s)

2

3

4

6

8 10

Turns N°

4.0

25% OPEN

3.0

2.0

1.0

0.3

0.5

1.5

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

3.37

4.08

4.51

5.12

5.60

6.16

6.78

1

7.32

7.90

8.43

9.00

9.53

9.88

10.30

10.73

11.16

11.63

2

11.97

12.36

12.78

13.19

13.53

13.92

14.28

14.57

15.01

15.35

3

15.69

16.01

16.43

16.71

17.02

17.24

17.52

17.85

18.10

18.27

4

18.69

ART 22

V1

Kv Values - DN 50

ART 22

Kvs=42.3

Turns N°

4.0

3.0

2.0

1.0

25% OPEN

0.3

0.5

1.5

36

P

V

=

Q

K

20

30

40

50

60

80

0.2

0.3

0.4

0.5

0.6

0.8

8

6

5

4

3

2

1

0.1

Pr

essur

e Loss -

∆p

(kPa)

2

10

100

Flow rate -

Q

(l/s)

0.2

0.4

0.6 0.8 1

3

4

6

8 10

20

Kv (Flow rate in m

3

/h @ 1 bar pressure drop)

Full turn

Tenths of turn

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0

-

-

-

4.39

5.65

6.72

8.07

8.97

10.04

11.06

1

11.77

12.62

13.51

14.28

15.05

15.73

16.25

17.14

18.06

18.81

2

19.44

20.10

21.04

21.81

22.53

23.12

23.88

24.28

24.75

25.36

3

26.06

26.48

26.91

27.24

27.66

28.10

28.44

28.80

29.17

29.76

4

30.10

ART 22

This fixed orifice double regulating valve is a precision manufactured product and should be

handled, installed and used with care as detailed in these instructions.

ART 22 balancing valves are suitable for both heating (LPHW) and cooling

applications at working pressures up to 25 bar.

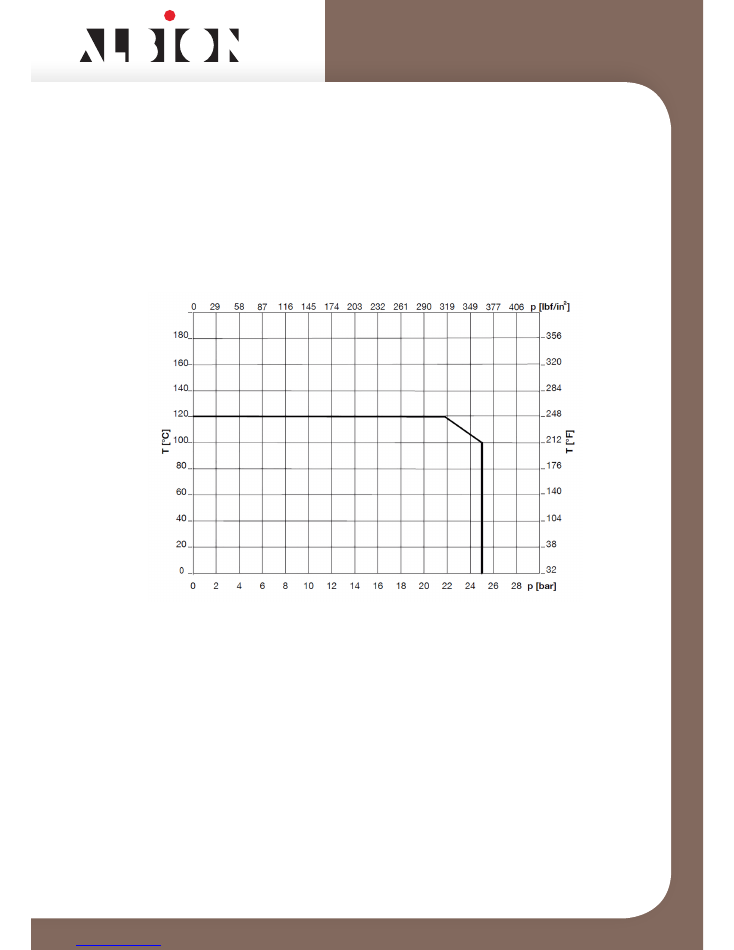

Operating Pressure and Temperature

DZR Fixed Orifice Double Regulating Valve

Limits of Use

The valve is rated PN 25 and must be installed in a piping system where the normal

pressure and temperature does not exceed the above ratings.

The upper temperature is restricted to 120°C due to the elastomeric seals in the test points.

Layout and Siting

It should be considered at the design stage where valves will be located to

give access for operation, regulation and setting to the required position.

V1

ART 22

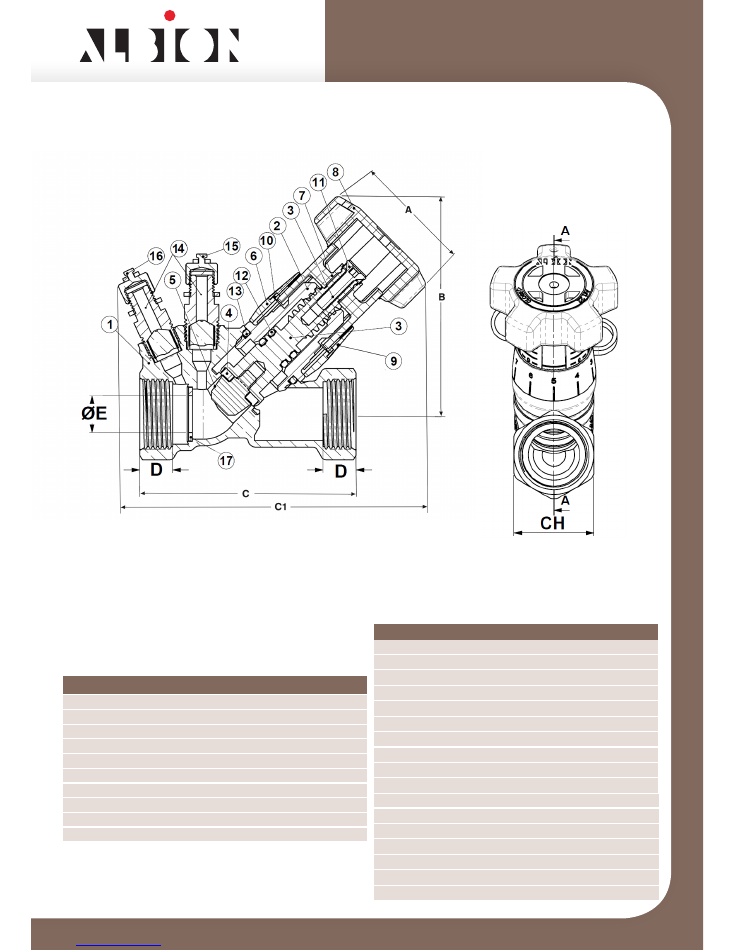

DN

½”

¾”

1”

1¼”

1½”

2”

A

50

50

50

50

50

50

B

83 82

84

87

107

103

C

72.5 82

95

122

138

161

C1

113 116.5 130

131

149

164

D

12.5 12.5 14.5

16

16

19

CH

25 31

38

47

55

66

Kv

2.00 3.88 7.28

13.39

18.69

30.10

Kvs

2.3 5.3

9.2

19.0

22.1

42.3

ØE

9

14

17.5

25

27

36.7

Kgs

0.78 0.43 0.52

0.86

1.34

1.47

N.

Part Name Materials

1

Body DZR Brass

2

Bonnet DZR Brass

3

Stem DZR Brass

4

Gasket EPDM

5

Shutter DZR Brass

6

Index POM

7

Entrainer Blue Nylon 6

8

Knob Blue Nylon 6

9

1/10 Turn index blue POM

10

Ring Brass

11

Screw Steel

12

O-Ring EPDM

13

O-Ring EPDM

14

Binder Point Brass

15

Cup Blue Brass

16

Cup Red Brass

17

Fixed Orifice DZR Brass

V1

ART 22

Installation

Valves are precision manufactured products and should not be subjected to misuse.

Careless handling, allowing foreign particles to enter the valve through the end ports, lack

of cleaning both valve and system before operation should be avoided. Excessive force

during pipe tightening and handwheel operation should be avoided.

Valves must be provided with adequate support. Adjoining pipework must be supported

to avoid the imposition of pipeline strain onto the valve, which would impair its

performance.

Immediately prior to installation, the adjacent pipework should be checked for

cleanliness and freedom from debris.

Confirm that the pipe threading is correct to avoid excessive penetration of the

pipe into the valve, which may cause damage.

Thread sealing compounds appropriate to the application must be used but excessive

use should be avoided, since this increases thread interference and may cause

overstressing of the body ends and may cause thread seal to extrude into the bore,

disturbing the flow condition.

Ensure the threads are properly engaged before proceeding to tighten the valve

onto the pipe.

The wrench must only be located on the valve end into which the pipe is being

threaded to avoid distortion of the valve.

Fixed orifice double regulating valves should be installed with a minimum of 5 diameters

equivalent of straight pipe upstream and 2 diameters downstream having the same

nominal diameter as the valve and should not include any reducers or any

other intrusions into the bore within these specified lengths.

It is important to ensure that the flow arrow on the valve is coincident with the

direction of flow in the pipeline.

V1

ART 22

Operating

When used for balancing water distribution systems, valves will always be in the fully open

position at commencement of any commissioning or flushing exercise.

Regulation is accomplished by rotating the handwheel clockwise when viewed

from the top of the handwheel.

The valve is opened by anti-clockwise rotation of the handwheel to a positive stop.

Further effort is not necessary. When fully open it is advantageous to rotate the

handwheel clockwise 1/2 turn.

To close the valve, the handwheel is rotated clockwise to a positive stop.

Test points

Valves are supplied with test points fitted.

Operation

The commissioning stage is the only time that the valve will normally have any attention.

During this stage, all entrained air must be removed from the system before

accurate measurements of differential pressure signals can be taken from the test

points.

There are two test points, each fitted with a coloured strap and captive cap.

• Upstream (HP) – Red

• Downstream (LP) - Blue

For safety reasons, all manometer probe insertions must be carried out with the

system cold.

The measurements are taken by directly inserting the test probe into the test point.

A silicone oil or grease should be lightly applied to the shaft of the probe prior to

insertion. No other type of lubricant should be used.

Valve Setting

When the regulated position is achieved, the double regulating feature is set as

follows:

• The inner spindle is adjusted through the central hole in the handwheel, using

a 3mm Allen key.

• Rotate the inner spindle anti-clockwise until a stop is felt.

• The double regulating feature is now set which enables the valve to be fullyclosed

for isolation and re-opened to the previously set position. It is recommended to record

this set position for reference later if necessary.

Maintenance

The Albion Art 22 does not require any routine maintenance.

V1