Full Text Searchable PDF User Manual

Floor Tiling

Installation Guide

Ancillary Products

A full range of high quality fixing and sealing products, researched and developed to

meet Fired Earth standards, are available for both professional and DIY use.

Read the instructions on the packaging of Adhesives, Grouts and Sealants very carefully.

Website

-

www.firedearth.com

All our installation guides are available to download from our website: Wall Tiling,

Underfloor Heating, Wood Flooring and Waterproofing Showers and Bathrooms.

Useful Numbers

UK Sales

0845 366 0400

Export Sales +44 (0)1295 814316

Installations

01295 814310

Technical

01295 814271

Home Deliveries

01295 814313

Customer Care

01295 814396

Disclaimer

The specifications and technical information given in this publication are intended for guidance and

although they are to the best of our knowledge correct, they are given without warranty.

We cannot accept any responsibility for reliance placed upon the advice contained herein since practical

expertise and site conditions are outside of our control. Neither do we accept liability for the performance

of the product arising from such use. This does not affect your statutory rights.

Fired Earth is a trading name of Aga Consumer Products Limited. Registered in England

and Wales under Registered Number 3872754. Registered Office Address - 4 Arleston Way,

Shirley, Solihull B90 4LH.

Fired Earth, Twyford Mill, Oxford Road, Adderbury, OX17 3SX

Tel: 01295 812088 Fax: 01295 810832 www.firedearth.com

© Aga Consumer Products Limited trading as Fired Earth. August 2008

Floor Tiling

Installation Guide

Contents

Substrates

4

Planning

6

Fixing

7

Cutting

8

Sealing

9

Grouting

10

Terracotta Tiles

11

Presealed Terracotta, Geometric,

Roman Mosaic and Encaustic Tiles

13

Slate and Lubelska Bricks

14

Natural Stone Tiles and Mosaics

15

Porcelain and Glass Tiles

16

External Floor Tiling

16

Glossary

16

Product Selector 1

18

(Adhesives, Grouts and Additives)

Product Selector 2

22

(Sealing, Finishing and Maintenance)

The purpose of this booklet is to outline the basic

principles of installing Fired Earth floor tiles. For more

detailed technical information, refer to British Standard

BS 5385 Wall and Floor Tiling.

Important Notes:

Prior to installation please ensure the tiles purchased

are suitable for the application. All tiles must be

thoroughly inspected prior to installation. Ensure your

tiler is aware of the expected finish of the tiles and there

are sufficient tiles for the area. The tiles must be well

shuffled by drawing tiles from all the boxes. Dry lay an

area in suitable light as a final check before installation.

No complaints regarding the appearance of the product

will be accepted by the company once the tiles have

been installed.

For further information or if any doubt exists, please

telephone our Technical Department for advice prior to

commencing any tiling.

Fired Earth have tested our range of adhesives, grouts and

sealants to ensure compatibility with all our tiles (see our

Product Selector on page 18-23). Read the instructions on

the packaging of Adhesives, Grouts and Sealants very

carefully. Keep everything meticulously clean and orderly

as work progresses.

5

Substrates

If your tiling is to last, it is essential that

the surface onto which the tiles are to be

laid is sound. Careful consideration must be

given to the floor surface to confirm that

the surface is level, clean, dry, free of dust,

grease and any loose material.

Your tiler must confirm the suitability of

the subfloor before tiling.

Sand and cement screeds

When tiling onto a new screed, a minimum

period of one week for each 25mm of new

screed should elapse to allow the screed to

be suitably dry. Further time may be

necessary, depending on weather and site

conditions. We do not recommend tiling

onto anhydrite or fast setting screeds

without careful consideration - please

contact our Technical Department for

further advice.

A new screed may shrink as it dries, and

this may result in cracks across the screed.

If cracking does occur it is likely to appear

across any tiles that are fixed to the screed.

Ensure that the screed is suitably dry and

stable before any tiling is started.

Any movement or day joints in the screed

must be carried through into the tiled

surface. Day joints or construction joints

must not be tiled over without the

inclusion of an expansion joint.

Bumps and hollows

in screeded floors

Minor irregularities can be overcome with

up to 5mm of

Fired Earth Universal

Levelling Compound*

or

Fired Earth Thick

Bed Adhesive*.

If the floor is very uneven,

with undulations of more than 5mm,

Fired

Earth Universal Levelling Compound*

should be used in conjunction with clean

granite chippings.

Suspended timber floors/

Floating insulated floors

Suspended timber floors/floating insulated

floors (polystyrene with water resistant

chip board over) should be rigid, non-

flexing and stable enough to bear the

additional load. In order to minimise the

damaging effect of lateral movement in the

floor surface, it is recommended that the

floor is prepared using

Fired Earth

Fleximat*

. Our Sales Team will be happy to

provide our separate information sheet.

If the suspended timber floor is subject to

vertical movement, the floor must be

stiffened. Remove flexing by fixing a

minimum 18mm, WBP plywood over the

existing timber, screwed down at 150mm

centres. If the floating insulted floor is

subject to vertical movement the floor

must be braced by screwing and gluing

WPB plywood to its surface, or removing

4

some of the boards so 'bearers' can be

fitted below to provide further support.

Seal all the surfaces of the plywood boards

with

Fired Earth Universal Bonding Agent*

Other types of floors

Fired Earth would recommend that all

existing floor covering and residue adhesive

are removed before tiling. However it is

possible to tile over existing tiles provided

the surface is completely sound, secure and

thoroughly cleaned to remove all

contaminants such as oil, wax and grease,

using an appropriate cleaner.

Cork and woodblock floors must be

removed and any bitumen left on the

subfloor should be scraped away and all

loose material removed.

Vinyl tiles must be primed with

Fired Earth

Universal Bonding Agent*.

Damp

Prior to fixing tiles, damp of any nature

should be rectified. Consult a specialist if

any doubt exists.

Finished floor level

The finished level of an existing floor will

be raised by the maximum thickness of the

tile plus approximately 3–4mm adhesive

bed. Any resultant discrepancy with the

levels of adjoining rooms can be minimised

with the use of threshold/reducer strips.

Underfloor heating

Fired Earth floor tiles can be used over most

underfloor heating systems. The heating

should be correctly commissioned prior to

tiling and switched off during tiling. There

must be no cracks in the screed otherwise

any floor tiles fitted on top will crack.

Fired Earth Fleximat*

can be used as an

anti-fracture membrane over Fired Earth

Underfloor Heating. Our Sales Team will

be happy to provide our separate

information sheet.

Always use flexible adhesive and grout and

provide an expansion gap around all

perimeters and abutments. As a general

guide, do not tile continuously over areas

with a length of over 6 metres, fit an

expansion gap to prevent stress building up

in the floor. Always fit expansion joints in

doorways of adjoining tiled rooms.

DO NOT switch the heating on for at least

two weeks after tiling, then, starting from

ambient temperature, do not increase the

temperature by more than 5°C in a 24

hour period until the normal working

temperature is reached.

'Wet' floors

Please refer to our

Waterproofing Showers

and Bathrooms Installation Guide

for

further advice.

Walls

When tiling onto walls with floor tiles,

consideration must be given to the weight

of the tile and suitability of the substrate.

Our Sales Team will be happy to confirm the

weight of any of our tiles.

Step 4.

When tiling commences you should

start at point ‘X’, so check that the lines you

have marked make a perfect right angle and

the side line runs parallel to the centre line.

Grout joints

The width of grout joints will vary between

3–12mm. Large joints will be necessary on

rustic tiles such as terracotta and slate.

Please refer to the Fired Earth price list for

recommended grout joints.

Roman Mosaic tiles should be butt jointed

(no allowance made for a grout joint)

except when used in a shower where a

narrow but impervious grout joint will

be necessary.

When fitting random sized tiles an area

should be 'dry laid' first to establish the

optimum joint width. Joint sizes may vary

from 2mm-10mm across the floor

depending on the mixture of tile sizes

used and the pattern.

Mosaic tiles -

Ensure that the sheets of

mosaic tiles are spaced so that once

grouted, no individual sheets can be

distinguished.

Particular care is required when blending

individual sheets of mosaics, to ensure a

subtle blend of colour is achieved.

Damp Tiles

Damp tiles should be stored on end in a

well ventilated area to dry thoroughly

before fixing. This may particularly apply

to Natural Stone, Lubelska Brick and

Reclaimed Terracotta and Encaustic tiles.

In general, the following weights apply to

the list of substrates, provided they are fixed

correctly and sound and stable;

Plaster - 20 kg/m

2

: Plasterboard - 32 kg/m

2

Brick/block/render - 40 kg/m

2

+

Tile Backer board/wbp plywood - 40 kg/m

2

+

7

6

Planning

Take the time to study the room and plan

your work. Tiling usually commences in the

corner furthest from the door. If there is

more than one door, it will be necessary to

decide which is the primary entrance.

Consider how cuts will look against fixed

furniture etc. and through doorways.

Adjustments may be required to achieve

the best results.

Please note: Where tiles have variable depths

e.g. Reclaimed Terracotta the thickest tile

including the adhesive should be taken as the

approximate floor height increase.

Step 1.

Mark the centre line of the room

from the wall of the primary entrance to the

far end. You will need to measure and mark

the midpoints of walls A to B and C to D.

Join these two points with a taught chalk

line and mark.

Step 2.

Mark the midpoint of the room by

measuring the centre of the line. From this

point, lay down tiles (without fixing them)

alongside the centre line, allowing for joints,

to see where the last whole tile will end.

Mark (with string or chalk) a line 1 to 2 at a

right angle alongside this last whole tile.

Step 3.

Locate starting point ‘X’ by laying

down tiles along the new line 1 to 2 in the

same way as before, to see where the last

whole tile will end. Now mark your side line

3 to 4 at a right angle alongside this last

whole tile.

Fixing

Before commencing tiling please ensure

you are familiar with the important notes

on page 3.

It is important to establish which way the

tiles are to be laid before any tiling is

started. Make sure the person fitting the

tiles knows what the tiles should look like.

‘Shuffle’ the batch to ensure that any

colour and tonal variations are well mixed.

Minor chips and blemishes should be

expected and are best used for cuts or well

mixed into the floor.

Some of our tiles vary considerably in depth.

Where this is applicable, it is important to

grade the tiles before installation.

Some of our tiles require careful sealing

prior to installation. (See page 9 onwards)

Be certain that the tiles are suitable for the

application.

midpoint

centre line

A

B

C

D

4

3

X

first tile position

1

2

9

8

Cutting

Due to the thickness and make-up of the

majority of Fired Earth floor tiles, it is

recommended that either a diamond cutter

or an angle grinder is used to cut the tiles.

Water cooled diamond cutters are available

from tool hire shops.

Please wear suitable protective eyewear and

protective clothing when cutting tiles.

Porcelain tiles require high quality diamond

blades for cutting.

Drilling holes can be a difficult task without

the correct equipment. Fired Earth

Terracotta, Lubelska Bricks and Slate floor

tiles can be irregular or bowed and may

require a greater depth of adhesive in order

to ‘iron out’ potential irregularities in the

finished surface.

Fired Earth Thickbed

Adhesive

* is perfect for this purpose as it

can be used up to 25mm in depth.

Using a suitable notched trowel, spread an

area 1 square metre to a depth of

approximately 4mm. ‘Butter’ the back of

the tile with a further 2mm of adhesive and

place the tile in the starting position as

described in the Planning Steps 1 to 4.

When using

Fired Earth Thickbed Adhesive*

,

use a ‘large format’ trowel to apply the

correct bed of adhesive to the subfloor.

When laying thin, machine made glazed,

porcelain or quarry tiles to an even surface

it may be possible to fix the tiles directly

onto a thin bed of adhesive, without having

to ‘butter’ the back of the tile.

Stone or glass tiles are normally fixed with

white adhesive to prevent the colour of the

adhesive 'bleeding' through. Push the tile

home firmly with a slight twisting

movement. Place the next tile adjacent to

the first, allowing for the grout joint, and

so on over the prepared area.

All the tiles should be soundly bedded in

the adhesive without any space for air

underneath. Be careful not to allow any

adhesive onto the surface of the tiles. Any

surplus should be wiped away with a clean

damp sponge. Once a square metre area

has been tiled, another similar area should

be prepared and so on until you have

completed the floor with whole tiles. The

remaining perimeter area should now be

prepared and cut tiles laid. If you prefer

cuts can be fitted as the work progresses.

Check the floor level as work progresses

with a spirit level and a straight edge. Fixing

tiles into sand and cement should be

avoided because of the time required for the

tiles to dry out and the associated problem

of efflorescence.

recommend the use of the ARMEG® range

of porcelain drill bits and core drills.

When cutting or drilling the tile, the

surface may become wet and dirty. Wipe

the tile clean immediately after cutting.

Using a water cooled diamond cutter will

achieve the most accurate cut.

When using an angle grinder, mark the tile

where you wish to cut it, run the cutting

disc along the marked surface cutting the

tile to at least two thirds of its depth, then

the tile can be snapped. Rough edges and

chips should be smoothed and finished

with a sanding block or in severe cases, by

rubbing the tile edge with a broken piece of

another tile.

Roman Mosaic -

Metal reinforcing bars are

used in the manufacture of border designs

and may cause excessive wear on cutting

equipment. Care should be taken to ensure

that the pattern is correctly matched,

particularly in the case of the basketweave

design. Small pieces of mosaic can become

detached during cutting and should be

glued back into place using an epoxy or

similar glue.

Sealing

Many Fired Earth tiles require sealing to

prevent stains from penetrating the body of

the tile. Please refer to our Product Selector

on pages 18 -23 for more details.

Before sealing commences it is imperative

that the tiles are completely clean and dry,

otherwise you may actually seal in dirt,

cement dust and moisture which can impair

the final appearance.

The process of sealing should be kept

meticulously clean and all materials

including brushes and cloths etc., should

be new and unused.

It is equally important that the sealer soaks

into the surface of the tile, disappears and

is not allowed to ‘spoil’ (i.e. the hardening of

excess sealer on the tile surface).

Terracotta and Encaustic tiles must be

individually sealed prior to fixing.

With other tiles requiring sealing the

process is performed in two stages. The

first seal is applied once the tiles are fixed

but before they are grouted. The second

seal is applied over the whole floor, once

the tiles have been grouted and have

completely dried.

All sealers take a few days to oxidise and

will not be fully effective during this time.

Therefore keep traffic across the floor to a

minimum for the first week.

Grouting

Grouting refers to the process of filling the

spaces between the individual tiles and

thus completing the floor surface. Before

grouting can commence, the adhesive used

must have cured, which usually takes

between 12–24 hours for

Fired Earth Floor

Adhesive*

and 3 hours for

Fired Earth

Fastset Adhesive*.

The depth of adhesive,

ambient temperature, porosity of the tile

and subfloor will all affect the curing time.

The joints to be grouted should be clean,

dry and free of loose debris and excess

adhesive. The addition of

Fired Earth

Flexibond*

will increase durability and

impart flexibility to the grout.

Fired Earth

Flexibond*

should be added to the grout

when tiling onto timber floors prepared

with WBP plywood, floating floors, tiles

over underfloor heating and 'wet floors'.

It is advisable to grout and clean a small

‘test’ area prior to grouting the whole floor.

This will give you the opportunity to check

that all grout can be removed without

staining the tiles and that you are happy

with your chosen colour.

Pointing and Slurry Grouting

Pointing is the careful application of grout

between the tiles avoiding contaminating

the surface of the tile by using a damp

sponge to wipe off any excess.

Slurry grouting is the method of grouting

involving a wet mix, or slurry of grout

being spread over the whole of the tile

surface, as well as into the grout joints. The

slurry is then pressed with a ‘grout float’ or

squeegee into the grout lines and into any

pits in the surface of the tile. Any surplus

should be wiped off the tiles particularly

before it starts to dry with a clean damp

sponge, continuously washing the sponge

using clean warm water.

The addition of

Fired Earth Flexibond*

into

the grout makes removal of surplus grout

more difficult, so it is important to clean as

you grout.

Grout should be pushed well down into the

joints so that no air pockets exist and the

joints are fully filled. The more the grout is

compacted the harder it will set. A timber

dowel of the appropriate diameter may be

used to assist in compacting the grout.

Smooth off the joints and remember that

the main purpose of grouting is to

strengthen the overall floor and, in order to

achieve this, the grout must fully support

the edges of all the tiles.

Fired Earth offers grouts for floors in

three colours,

Sandstone

,

Grey

and

Limestone*

. We do not recommend the use

of strong pigmented grouts which are

more likely to stain the tile. As soon as

the floor is finished and the grout has

completely dried, the tiles should be

thoroughly cleaned to remove any stains

or fine dust particles.

Terracotta Tiles

(except Presealed Terracotta)

Sealing

Fired Earth recommend Terracotta tiles are

sealed

with Fired Earth Linseed Sealer*

prior to fixing. We would advise that a

number of sample tiles are tested for

porosity, from which an indication of the

amount of sealer that the tiles will absorb

can be gauged.

Using a clean, short haired paint roller or

brush, work the sealer into the surface so

that the tile appears matt again within 10

minutes. If the tile regains its matt

appearance too quickly, use the sealer a

little more liberally.

The tiles will readily absorb the first coat of

sealer and, as a rough guide, you should

expect to use up to 75% of the sealer on

the first coat. Within 20 minutes of applying

the sealer, check that there is no surplus

remaining on the surface of the tiles.

Wipe away any surplus sealer with a clean,

dry cloth. If oil is allowed to remain on the

surface for 20 minutes or more, it is likely

that the oil will begin to turn tacky or hard,

which will necessitate remedial work. The

final seal can only be carried out once the

grouting has completely dried.

Take particular care during the application

of the second coat of sealer as the tile is

now partially sealed and will absorb less

sealer than the first coat. Apply a second

coat to a small test area to gauge how

much sealer the tiles are likely to absorb.

Remember the oil should soak in within 20

minutes of application and the tiles should

be matt in appearance.

Finishing

Option A - Wax Polish

Once sealed, Fired Earth’s traditional

method of finishing terracotta is for

Fired

Earth Wax Paste*

to be applied. This

enhances the natural colours within the

clay and provides protection against

staining. Apply the first coat as soon as

possible after the sealer has dried. The wax

should be applied sparingly, allowed to

harden then buffed to form a hard,

protective finish. For a newly installed floor,

Fired Earth Wax Paste*

should be applied

once a week for the first 4–6 weeks, in

order to build up a hard wearing surface.

Option B - Cotto Rapid*

As an alternative finish, providing less

protection but requiring less maintenance,

Cotto Rapid*

can be applied once the tiles

have been sealed for the second time.

Ensure the sealant is completely dry before

application of this product. Two to three

coats should be applied sparingly with a

clean cloth, allowing sufficient drying time

between coats.

Cotto Rapid*

should be re-applied once or

twice per year.

Cotto Rapid*

is not

recommended for use on Fired Earth Antique

11

10

Pammets because salt pits cannot be

'blended in' without the use of wax polish.

Maintenance

Terracotta floors should be swept or

vacuumed regularly to remove all loose dirt.

It is important to use the correct Fired Earth

products when maintaining your floor, as

these have been formulated to both clean

the floor and be gentle on the sealants.

Spillage and cooking stains should never be

allowed to remain on an unglazed floor and

should be wiped off immediately with a

clean, damp cloth. More stubborn marks

can usually be removed using white spirit.

Terracotta finished with wax polish

Between waxing, the floor should be

washed with

Fired Earth Super Floor*

diluted in clean, warm water. Avoid harsh

or abrasive floor cleaners.

For most domestic floors it is advisable to

apply further wax coats from time to time.

The frequency will be dictated by the wear

and washing the floor receives. If a build

up of wax becomes visible, reduce the

frequency of waxing. Likewise, if the tiles

are marking or look dull and dry, increase

the frequency.

Terracotta finished with

Cotto Rapid*

Floors should be wiped clean using

Fired

Earth Stone Clean

* - diluted with water.

Reapply

Cotto Rapid*

when the floor

appears dull.

General characteristics

Efflorescence -

Terracotta contains various

soluble minerals and salts which can be

activated by damp and moisture. This may

appear as a white stain or ‘bloom’ on the

surface and should be wiped away with a

clean damp cloth. Stubborn efflorescence

may be removed with a cement stain

remover, such as

HG Extra Cement/Grout

Remover*

. Do not soak terracotta tiles

during fixing as this may activate

efflorescence.

Streaking -

This occurs when terracotta is

sealed with a dirty brush, dirty oil or uneven

application. As soon as streaking is noticed,

stop sealing and eliminate the cause.

Sweating -

Terracotta tiles can sweat and

on occasion may actually exude recently

applied sealer. This might happen when cool,

damp tiles are sealed in a hot environment

or if a new floor is sealed in an unoccupied

property in mid-winter. Avoid sealing

terracotta tiles under these conditions.

Salt pits -

Salt occurs naturally in

terracotta. In certain situations the salt is

drawn to the surface and creates craters or

blistering. Should this occur, fill the craters

with grout, reseal and finish.

Mildew -

If terracotta tiles are sealed while

damp, or the subfloor is damp, there is a risk

of mildew forming in the tiles. This will

appear as black or white marks and spots.

For further information contact the Fired

Earth Technical Department.

13

12

Presealed Terracotta

These tiles require no sealing.

Finishing

Apply one coat of

Cotto Rapid*

. The use of

this product on Pale Presealed Terracotta

may darken the appearance. Reapply

Cotto Rapid*

when the floor appears dull.

Maintenance

Presealed terracotta floors should be swept

or vacuumed regularly to remove loose dirt.

It is important to use the recommended

Fired Earth products when maintaining

your floor as these have been formulated

to both clean the floor and be gentle on

the sealants. Floors should be wiped clean

using

Fired Earth Stone Clean*

diluted

with water.

Geometric and Roman Mosaic Tiles

Sealing

Geometric tiles should be sealed with two

sparing coats of

MN Stain Stop*

. They

require no further sealant or finishing. Fired

Earth Roman Mosaic tiles do not require

sealing prior to grouting. Apply 2 coats of

MN Stain Stop

* after grouting.

Maintenance

Tiled floors should be swept or vacuumed

regularly to remove all loose dirt. It is

important to use the correct Fired Earth

products when maintaining your floor, as

these have been formulated to both clean

the floor and be gentle on the sealants.

Spillage and cooking stains should never be

allowed to remain on an unglazed floor and

should be wiped off immediately with a

clean, damp cloth. More stubborn marks

can usually be removed using white spirit.

Floors should be wiped clean with

MN Easy

Care*

diluted with water.

Encaustic Tiles

Due to the very porous and delicate nature

of this tile, extreme care must be taken

with handling and installing.

Fired Earth recommend the use of our

installation service for this tile. Please

discuss further details with a member of

our Sales Team.

Detailed fitting instructions must be

followed. These can be obtained through

our sales teams in store or via our Technical

Department (see page 24 for contact

numbers).

15

14

Slate and Lubelska Bricks

Sealing

Before grouting apply one or two coats

of

Fired Earth Stone Shield*

using a clean,

fluff-free cloth. Allow approximately 2

hours between applications and do not

apply more sealer than can be fully

absorbed by the tiles within 20 minutes.

Surplus sealer should be removed with

white spirit.

Lubelska Bricks can vary enormously in

porosity. In some cases a litre of sealant

may be required per 3m

2

of tiles. Apply

the sealer liberally to ensure thorough

sealing. Surplus sealer should be removed

in 20 minutes.

Finishing

In wet areas e.g showers, no finishing

product should be used.

Slate -

After grouting apply a first coat of

Fired Earth Stone Finish*

evenly and

sparingly over both the tiles and grout with

a soft, fluff-free cloth. The second coat

should be applied at right angles to the first

coat after 20 minutes. Further coats should

be applied at least once a year or more

frequently as required.

Lubelska Bricks -

After grouting, the tiles

are finished with

Cotto Rapid*

. Two to three

coats should be applied sparingly with a

clean cloth, allowing sufficient drying time

between coats. The third coat is more likely

to provide a semi-gloss finish.

Maintenance

Tiled floors should be swept or vacuumed

regularly to remove all loose dirt. It is

important to use the correct Fired Earth

products when maintaining your floor, as

these have been formulated to both clean

the floor and be gentle on the sealants.

Spillage and cooking stains should never

be allowed to remain on floor and should

be wiped off immediately with a clean,

damp cloth.

Fired Earth Super Floor* -

Tiles finished

with

Fired Earth Stone Finish*

should be

wiped over with

Fired Earth Super Floor*

diluted in clean, warm water.

Tiles finished with

Cotto Rapid*

should be

wiped clean with

Fired Earth Stone Clean*

diluted with water. Reapply

Cotto Rapid*

when the floor appears dull.

Product notes

Slate -

A certain amount of delamination

should be expected from slate tiles during

and following installation. During

installation any loose flakes should be

broken off. Where delamination occurs

after installation, the affected area should

be resealed. Slate tiles should not be

installed in areas subject to direct and

intense heat, as this may cause extensive

delamination.

Uncalibrated Slate -

Because of the great

variation in the depth of individual

Natural Stone Tiles and Mosaics

Sealing

MN Stain Stop*

will maintain the natural

appearance of the tile.

Fired Earth Stone

Shield*

will enhance the colours and deepen

the appearance of the natural stone.

Before grouting apply one to two coats of

appropriate sealant. Once the grouting has

completely dried and the tiles are clean and

dry, apply one further coat with a fluff-free

cloth. Any excess sealant should be wiped

off before it dries with a clean, dry cloth.

Ensure the grout is fully sealed.

Finishing

If using

Fired Earth Stone Shield*

finish

with

Fired Earth Stone Finish*; spread

evenly and sparingly over both tiles and

grout with a soft, fluff-free cloth, unless in

a wet area where no finishing product

should be used.

If using

MN Stain Stop*

no finishing

product is required.

Maintenance

Tiled floors should be swept or vacuumed

regularly to remove all loose dirt. It is

important to use the correct Fired Earth

products when maintaining your floor, as

these have been formulated to both clean

the floor and be gentle on the sealants.

Spillage and cooking stains should never be

allowed to remain on an unglazed floor and

should be wiped off immediately with a

clean, damp cloth. Tiles will require resealing

from time to time, dependant on use.

MN Stain-Stop* -

Tiles sealed with

MN Stain Stop*

should be cleaned with

MN Easy Care*.

Fired Earth Stone Shield* -

Tiles sealed

with this product should be cleaned using

Fired Earth Super Floor*

diluted with clean

water. It is unadvisable to use

Fired Earth

Super Floor*

in wet areas.

Product notes

Honed and Filled Stone -

Occasionally the

filler in the stone may require repair by

simply infilling with Limestone grout* or a 2

part resin based filler which is available for

purchase from Fired Earth via our Technical

Department.

uncalibrated slate tiles, it is recommended

that the tiles are graded before installation

Pale Classic and Chipped Edge Slate -

Following the application of

Fired Earth

Stone Finish*,

these products must always

be finished and maintained using

Fired

Earth Wax Paste*.

Lubelska Bricks -

Lubelska Bricks are

irregular in size, and depth and this needs

to be taken into account when planning

and tiling. Being a reclaimed product, the

tiles will vary in colour, texture and size.

17

Porcelain and Glass Tiles

These tiles do not require any sealing or

finishing products. After grouting, the tiles

should be polished with a soft, clean cloth

to remove any remaining grout film. The

grout can be sealed with

MN Stain Stop*

to

prevent staining.

Maintenance

Clean your floor with an

MN Easy Care*

when required.

Colour change -

As the colour of each

batch of stone will vary, it is advisable to

confirm your choice of sealant by treating a

small number of test tiles prior to treating

the whole floor.

External Floor Tiling

Many of our tiles are suitable for external

use. As we sell our tiles all over the world,

atmospheric/climate conditions must be

taken into consideration.

For more information on specific tiles

please speak to our Sales Team or our

Technical Department.

Glossary

Adhesion –

The ability to stick

Angle Grinder –

Electrical tile cutting tool

Anhydrite Screeds –

Calcium based

screed, seek advice

Appliances –

Fridge, dishwasher etc.

Asphalt –

Black, bituminous base

Bedding –

Depth of material to seat tiles

Bitumen –

Black in colour, often used

as a glue to stick vinyl tiles

Bowed –

Convex or concave shaped tiles

Buffed –

Abrasion of a waxed surface

Butter –

Applying a thin bed of adhesive

to the back of the tile.

Butt Jointed –

Fixing tiles together tightly

with no allowance for a grout joint

Chalk Line –

Tool used to provide straight

line for setting out tiles

Chipboard –

A composition of

fibrous timber

Coatings –

Material applied to a surface

Compacting –

Pressing material firmly

into position

Cotto Rapid –

Surface sealer and finish

Curing –

Improvement in strength, hardness,

durability and other properties of a material

Damp Proof Membrane (DPM) –

A layer of impervious material installed

to prevent rising damp

Day Joints -

A ‘joint’ in the screed as a

result of a break in pouring the screed

Delamination –

Loss of some or all of a

naturally occurring layer of slate

Diamond Cutter –

Electrical cutting tool

Expansion Joints –

A space allowed in a

floor to allow for movement

Fired Earth Flexible Fastset Adhesive –

Flexible tile adhesive with improved

bond strength

Fired Earth Flexibond –

A liquid used as an

additive in adhesive or grout to increase

flexibility and bond strength

Fired Earth Fleximat –

An orange plastic

sheet used to prepare timber floors for tiling

Floating or Insulated Floor –

A thermally

efficient floor which is not physically

attached to its base

Filled Stone –

Where any naturally

occurring holes have been filled with

resin based filler

Finishing –

Process of applying final

coat of sealer

Grout Float –

Tool used to apply grout

Grout Joints –

Channel formed between

tiles to be filled with grout material

Honed Stone –

Mechanical process used

to smooth the surface of natural stone

Linseed Sealer –

Impregnating sealer

MN Stain Stop –

Impregnating sealer

Movement Joint -

An area which allows

for movement caused by change in

temperature/humidity etc.

Notched Trowel –

Tool designed to

apply a specified depth of adhesive

Oxidise –

Hardening reaction following

exposure to the air

Presealed –

Pre-treated with sealer

at the factory

Pointing –

Careful application of grout

between tiles using a tool to finish off

the joint

Sand and Cement Screed –

A mixture

laid to form an accurate flat base

Sealing –

Process of applying liquids to

reduce porosity

Slurry –

A thick creamy liquid

Spoil –

Excessive or surplus sealer

Squeegee –

Rubber edged tool to aid

removal of excess grout

Stone Clean 1 –

Cleaning agent

Fired Earth Stone Finish –

A surface sealer,

protector and finish

Fired Earth Stone Shield –

An

impregnating sealer

Straight Edge -

Tool used to ensure tiles

are ‘straight’ and ‘flat’.

Subfloor –

The surface on to which the

tiles are to be laid

Fired Earth Super Floor –

Cleaning agent

Thermal Movement –

Movement induced

by temperature change

Fired Earth Universal Bonding Agent -

Primer for surfaces prior to applying tile

adhesive.

Fired Earth Universal Levelling Compound –

Material used to remove unacceptable

variations of level in a subfloor, or bed

underfloor heating

Uncalibrated –

Tiles will vary in depth

Wax Polish –

Protective material originated

from bees wax

WBP Plywood -

Minimum 18mm deep,

suitable grade for floor tiling

16

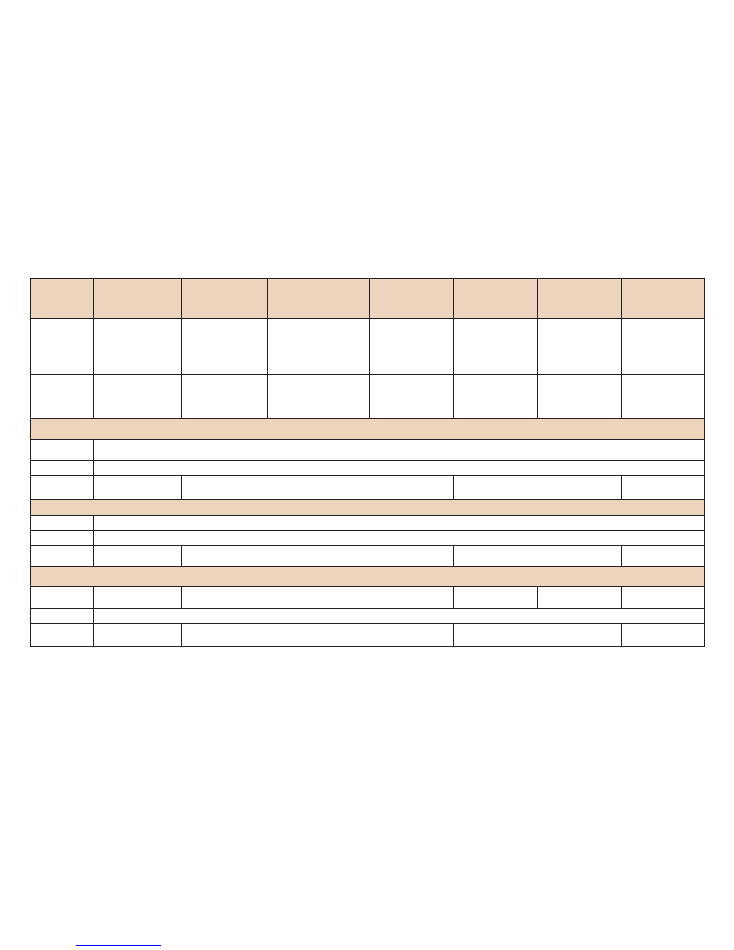

Substrate

Sand and

Cement Screed

Concrete/Brickwork

Timber

Floorboards

(sound and secure)

Timber Floorboards

overlaid with WBP

Plywood

(min depth 18mm)

Timber Floating

Floors

Quarry, Clay,

Glazed Tiles

Vinyl Tiles, Flooring

Grade Asphalt

(internal use only)

Underfloor

Heating

Watch Points

New concrete should be

allowed to dry for at least 6

weeks, cement sand screeds

3 weeks and cement sand

rendering 2 weeks

Must be screwed down to

joists and noggings and be

free from deflection

Countersink screws

to 150mm centres

If deflection exists in

floor, overlay with

plywood prior to using

Fleximat* or install

‘bearers’ between joists

Existing tiles must be

well fixed; any hollow

spots should be made

good and filled

Hollow or loosely fixed vinyl

tiles should be removed

along with their adhesive

residue, prime vinyl with

Universal Bonding Agent*

Fit in accordance with

manufacturers instructions.

Specification may vary

according to substrate

Preparation

If dusty or porous seal

with Fired Earth Universal

Bonding Agent*

Seal with Fired Earth

Universal Bonding Agent,

overlay with Fleximat

(see instructions)*

Seal with Fired Earth

Universal Bonding Agent*

Seal with Fired Earth

Universal Bonding Agent,

overlay with Fleximat

(see instructions)*

All surfaces must be

degreased and thoroughly

cleaned to remove old

polish residues etc

All surfaces must be

degreased and thoroughly

cleaned to remove old

polish residues etc.

Fit in accordance with

manufacturers instructions.

Specification may vary

according to substrate

PRESEALED AND RECLAIMED TERRACOTTA TILES AND LUBELSKA BRICKS

Tiles need to be dry before installation

Adhesive

Fired Earth Fastset Floor Adhesive or Fired Earth Thickbed Adhesive

with Lubelska Brick and Reclaimed Terracotta tiles*

Grout

Sandstone*

Additive

Not required

Fired Earth Flexibond* in both adhesive and grout

Not required

Fired Earth Flexibond* in

both adhesive and grout

ENCAUSTIC -

Tiles need to be dry before installation

Adhesive

Fired Earth White Floor Adhesive*

Grout

All Fired Earth grouts are suitable*

Additive

Not required

Fired Earth Flexibond* in both adhesive and grout

Not required

Fired Earth Flexibond* in

both adhesive and grout

SLATE TILES -

Tiles need to be dry before installation

(Use Thickbed Adhesive with all 40 x 60cm and 60 x 60cm Tiles)

Adhesive

Fired Earth

Fastset Floor Adhesive*

Fired Earth Flexible Fastset Floor Adhesive*

Fired Earth

Flexible Fastset Adhesive*

Fired Earth

Flexible Fastset Adhesive*

Fired Earth

Flexible Fastset Adhesive*

Grout

All Fired Earth grouts are suitable*

Additive

Not required

Fired Earth Flexibond*

Not required

Fired Earth Flexibond

Product Selector 1

- Adhesives, Grouts and Additives

Quick reference guide

19

18

*

Read the instructions on the packaging of Adhesives, Grouts and Sealants very carefully.

Notes:

Use this table in conjunction with Fired Earth Installation guides.

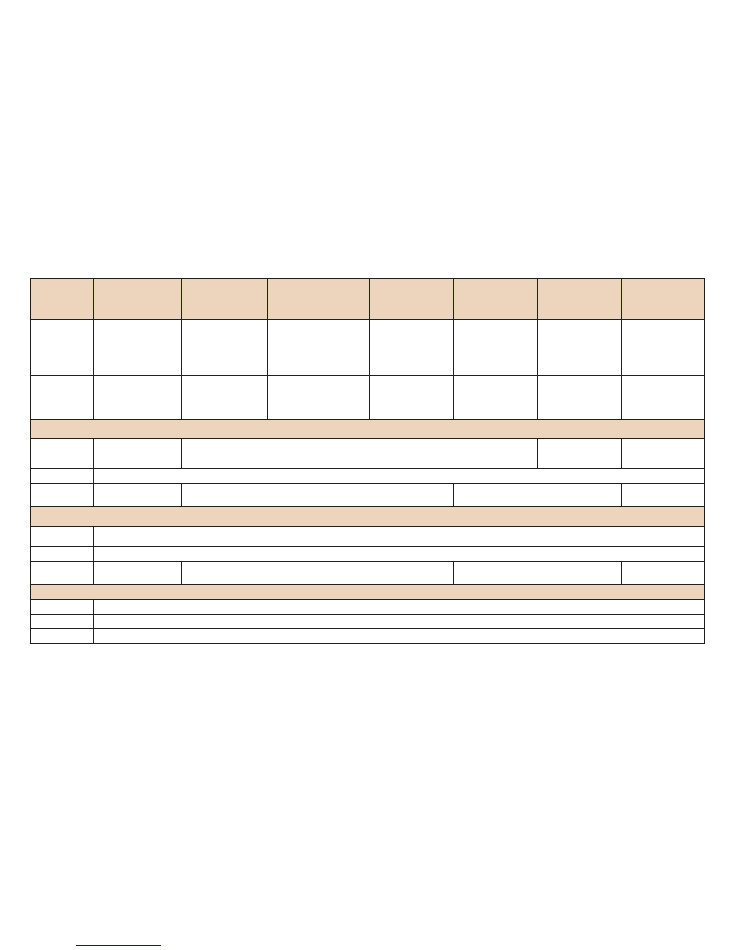

Substrate

Sand and Cement

Screed

Concrete/Brickwork

Timber

Floorboards

(sound and secure)

Timber Floorboards

overlaid with WBP

Plywood

(min depth 18mm)

Timber Floating Floors

Quarry, Clay,

Glazed Tiles

Vinyl Tiles, Flooring

Grade Asphalt

(internal use only)

Underfloor Heating

Watch Points

New concrete should be

allowed to dry for at least 6

weeks, cement sand screeds

3 weeks and cement sand

rendering 2 weeks

Must be screwed down to

joists and noggings and be

free from deflection

Countersink screws

to 150mm centres

If deflection exists in

floor, overlay with plywood

prior to using Fired Earth

Fleximat or install ‘bearers’

between joists*

Existing tiles must be well

fixed; any hollow spots

should be made good and

filled

Hollow or loosely fixed vinyl

tiles should be removed

along with their adhesive

residue, prime vinyl with

Fired Earth Universal

Bonding Agent*

Fit in accordance with

manufacturers instructions.

Specification may vary

according to substrate

Preparation

If dusty or porous seal

with Fired Earth Universal

Bonding Agent*

Seal with Fired Earth

Universal Bonding Agent,

overlay with Fired Earth

Fleximat (see instructions)*

Seal with Fired Earth

Universal Bonding Agent*

Seal with Universal

Bonding Agent, overlay

with Fleximat (see

instructions)*

All surfaces must be

degreased and thoroughly

cleaned to remove old

polish residues etc

All surfaces must be

degreased and thoroughly

cleaned to remove old

polish residues etc

Fit in accordance with

manufacturers instructions.

Specification may vary

according to substrate

NATURAL STONE TILES AND MOSAICS -

Tiles need to be dry before installation

Adhesive

Fired Earth White

Fastset Floor Adhesive*

Fired Earth White Fastset Floor Adhesive

with Fired Earth Flexibond added*

Fired Earth White

Fastset Floor Adhesive*

Fired Earth White Fastset

Floor Adhesive with Fired

Earth Flexibond added*

Grout

All Fired Earth grouts are suitable*

Additive

Not required

Fired Earth Flexibond in grout*

Not required

Fired Earth Flexibond

in grout*

GLAZED, PORCELAIN AND GEOMETRIC TILES

(Thickbed Adhesive can be used for all tiles 40 x 60cm and 60 x 60cm and above)

Adhesive

Fired Earth Flexible Fastset Adhesive*

Grout

Grey/Sandstone/Limestone*

Additive

Not required

Fired Earth Flexibond*

(grout only)

Not required

Fired Earth Flexibond

(grout only)*

GLASS TILES

(Use Thickbed Adhesive with all 40 x 60cm and 60 x 60cm Tiles)

Adhesive

Fired Earth White Fastset Floor Adhesive with Flexibond added*

Grout

White/Grey/Limestone*

Additive

Fired Earth Flexibond in grout*

Product Selector 1

(cont’d)

- Adhesives, Grout and Additives

Quick reference guide

21

20

*

Read the instructions on the packaging of Adhesives, Grouts and Sealants very carefully.

Notes:

Use this table in conjunction with Fired Earth Installation guides.

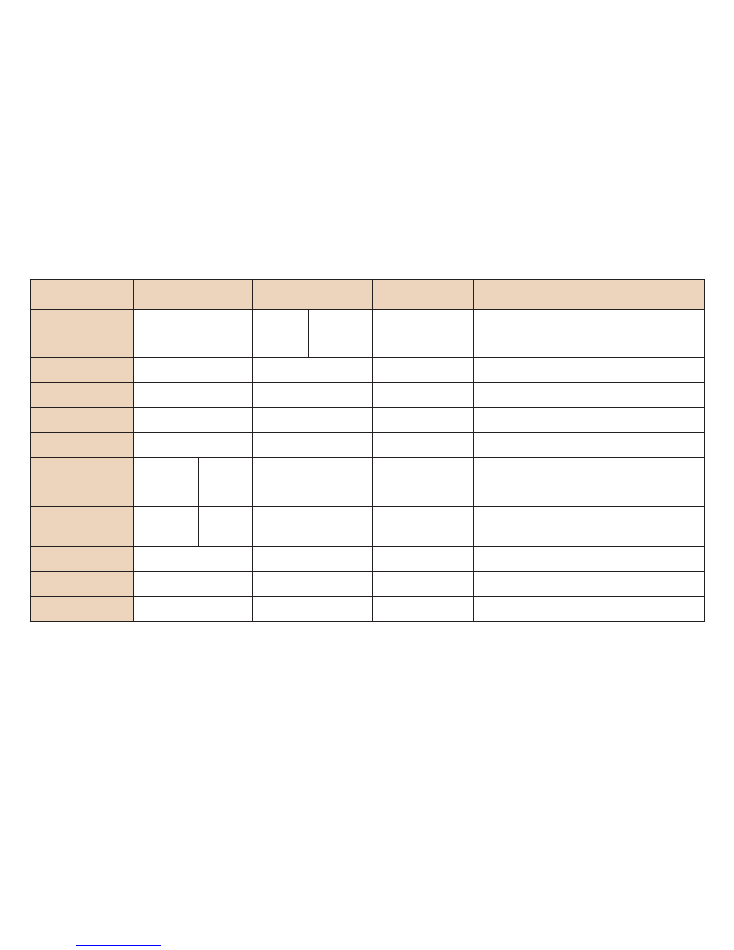

Product

Sealant

Finish

Cleaner

Maintenance

Terracotta

(inc. Reclaimed terracotta)

Fired Earth Linseed Sealer*

Wax paste (high

protection/high

maintenance/

colour enhancer)

Cotto Rapid

(low maintenance,

less protective)*

For waxed floors, use Fired Earth

Super Floor; for Cotto Rapid

floors, use Clean Stone 1*

For waxed floors it is advisable to apply further

wax coats from time to time; For Cotto Rapid floors,

reapply when floor appears dull*

Pre-sealed terracotta

Not required

Cotto Rapid*

Clean Stone 1*

Reapply Cotto Rapid when floor appears dull*

Lubelska bricks

Fired Earth Stone Shield*

Cotto Rapid*

Clean Stone 1*

Reapply Cotto Rapid when floor appears dull*

Encaustic

(follow specific instructions)

Fired Earth Stone Shield*

Fired Earth Stone Finish*

Fired Earth Super Floor*

Reapply Fired Earth Stone Finish when floor appears dull*

Geometrics

MN Stain Stop*

Not required

MN Easy Care*

Not required

Slate

Stone Shield

in dry areas*

MN Stain Stop

in wet areas*

Fired Earth Stone Finish if using

Fired Earth Stone Shield only*

If finishing with Fired Earth

Stone Finish, use Fired Earth

Super Floor; if sealing with MN

Stain Stop* use MN Easy Care*

For wet areas re-apply MN Stain Stop* when tiles appears porous; For dry

areas, re-apply Fired Earth Stone Finish when tiles appear dull. Wax paste

will be required for Pale Classic and chipped edge tile (use only in dry areas)

Natural Stone

(inc. Stone Mosaics)

MN Stain Stop to

retain natural

appearance*

Stone Shield to

enhance natural

colours*

If sealing(dry areas only) with

Fired Earth Stone Shield, use Fired

Earth Stone Finish; if sealing with

MN Stain Stop no finish is required*

If finishing with Fired Earth

Stone Finish, use Fired Earth

Super Floor; if sealing with MN

Stain Stop use MN Easy Care*

For MN Stain floors, it is advisable to re-apply the MN Stain Stop if

tiles become porous. For Fired Earth Stone Finish floors, reapply when

floor appears dull*

Roman Mosaics

MN Stain Stop*

Not required

MN Easy Care*

It is advisable to reapply the MN Stain Stop*

if tiles becomes porous

Porcelain

Tiles do not require sealing; seal

grout joints with MN Stain Stop*

Not required

MN Easy Care*

Not required

Glass

Tiles do not require sealing; seal

grout joints with MN Stain Stop*

Not required

MN Easy Care*

Not required

Product Selector 2

- Sealing, Finishing and Maintenance

Quick reference guide

23

22

*

Read the instructions on the packaging of Adhesives, Grouts and Sealants very carefully.

Notes:

Use this table in conjunction with Fired Earth Installation guides.