Full Text Searchable PDF User Manual

Original Instructions

AGN2400B

PORTABLE GENERATOR SET

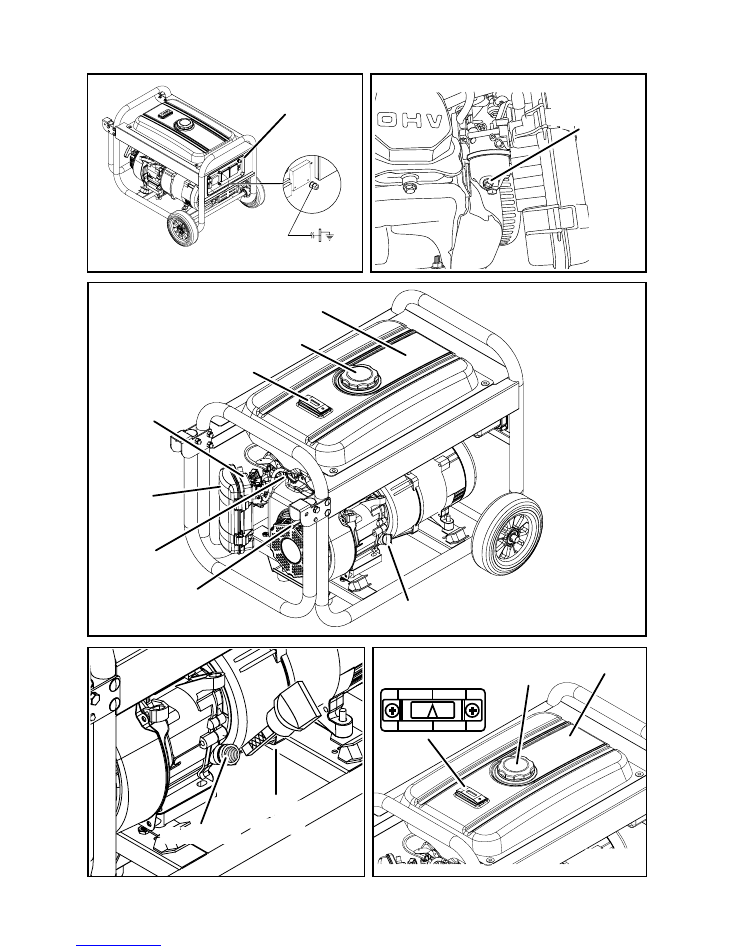

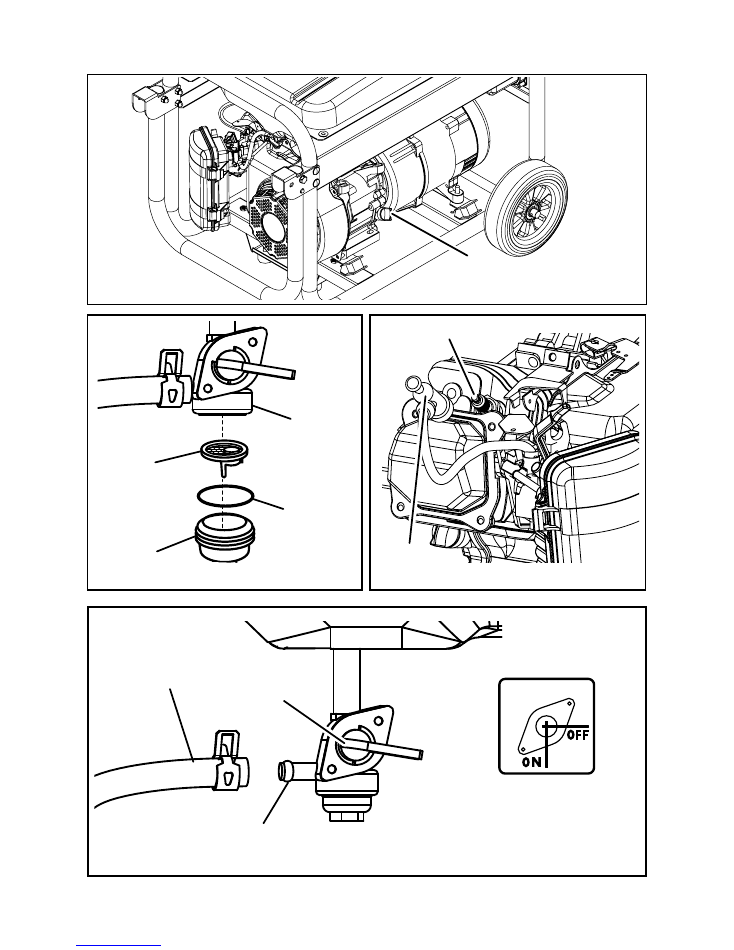

Fig. 1

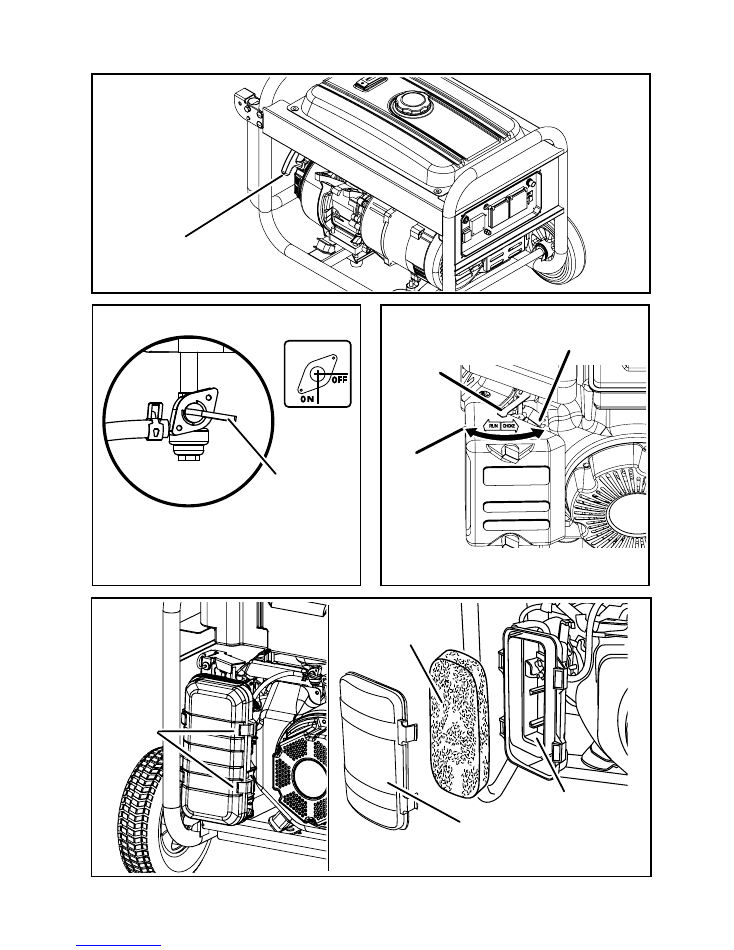

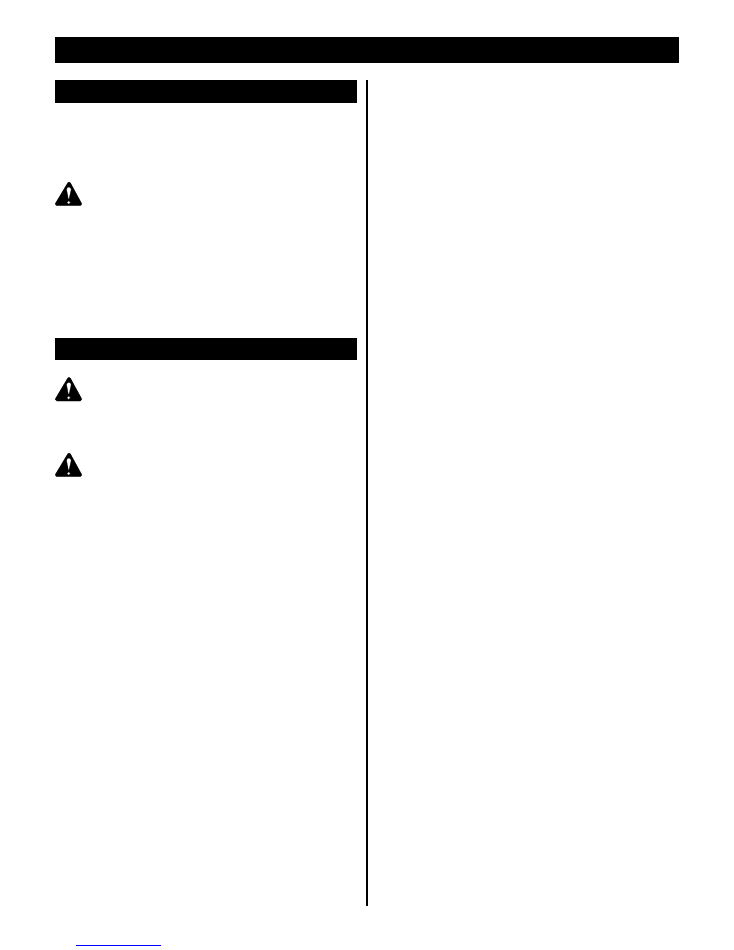

Fig. 4

Fig. 5

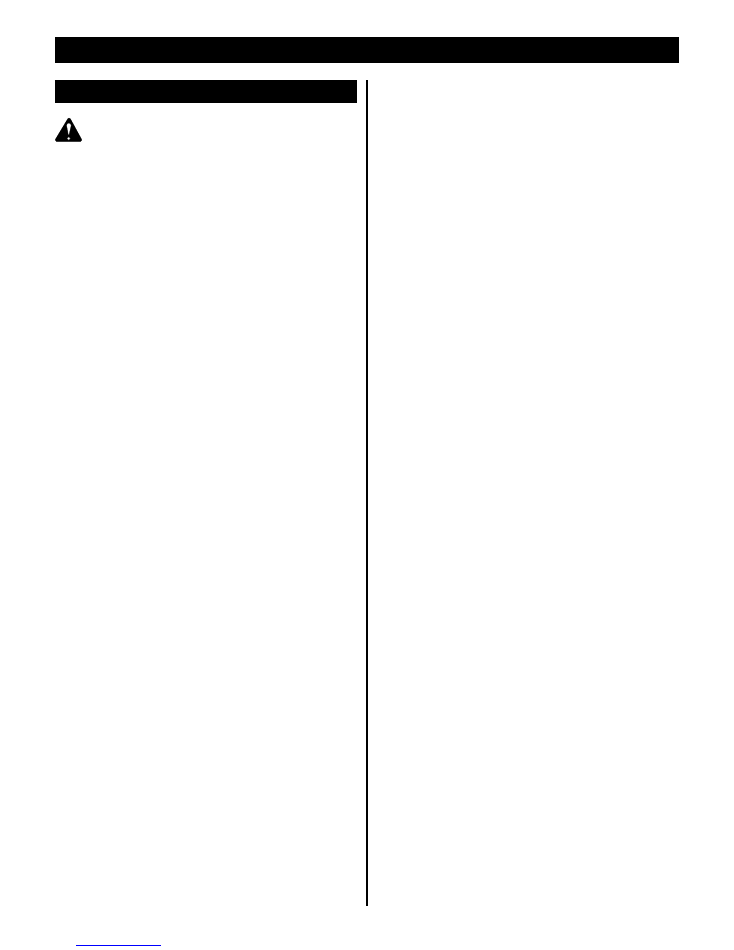

Fig. 3

oil cap/ dipstick

air

filter

choke

lever

fuel

valve

recoil

starter grip

fuel cap

fuel tank

fuel cap

oil cap/

dipstick

oil fill hole

carburetor

drain screw

oil cap/

dipstick

Fig. 2

fuel

level gauge

fuel

level gauge

circuit breaker

oil fill hole

fuel tank

Fig. 6

ON

OFF

ON

OFF

Fig. 8

Fig. 7

RUN CHOKE

choke

lever

to start (choke closed)

to run (choke

open)

recoil

starter grip

fuel valve

latches

air

filter cover

filter

elements

air filter unit

Fig. 9

21

2))

Fig. 10

ON

OFF

Fig. 11

Fig. 12

Fig. 13

ON

OFF

ON

OFF

spark plug

cap

spark plug

fuel

line

fuel

valve

barb

fuel

valve

o-ring

filter

sediment

cup

oil cap/ dipstick

1

English

INTRODUCTION

This product has many features for making its use more pleasant

and enjoyable. Safety, performance, and dependability have

been given top priority in the design of this product, making it

easy to maintain and operate.

DANGER

GROUNDING THE GENERATOR

(See Figure 1)

To avoid the risk of shock or electrocution, the generator

must be properly grounded. The nut and ground terminal

on the frame must always be used to connect the

generator to a suitable ground source. The ground path

should be made with 0.75m

2

size wire. Connect the

terminal of the ground wire between the lock washer

and the nut, and tighten the nut fully. Connect the other

end of the wire securely to a suitable ground source.

ImpORTANT sAfETy INsTRUCTIONs

WARNING:

Read and understand all instructions.

Failure

to follow all instructions listed below may result

in electrocution, fire, and/or carbon monoxide

poisoning, which will cause death or serious injury.

WARNING:

National Electric Code requires the generator to be

grounded to an approved earth ground. Before using

the ground terminal, consult a qualified electrician,

electrical inspector, or local agency having

jurisdiction for local codes or ordinances that apply

to the intended use of the generator.

sAVE THEsE INsTRUCTIONs

This manual contains important instructions that should be

followed during installation and maintenance of the generator

and batteries.

n

Do not allow children or untrained individuals to use this

unit.

n

Never start or run the engine inside a closed or partially

enclosed area. Breathing exhaust fumes will kill you.

n

Wear eye protection as well as hearing protection when

operating this equipment.

n

Keep all bystanders, children, and pets at least 3m away.

n

Wear sturdy and dry shoes or boots. Do not operate while

barefoot.

n

Do not operate the generator when you are tired or under

the influence of drugs, alcohol, or medication.

n

Keep all parts of your body away from any moving parts

and all hot surfaces of the unit.

n

Product users in some states, must comply with fire

prevention regulations. This product is not equipped with

a spark arrestor. Check with the federal, areas, or local

authorities in your area before use.

n

Do not touch bare wire or receptacles.

n

Do not use the generator with electrical cords which are

worn, frayed, bare, or otherwise damaged.

n

Before storing, allow the engine to cool.

n

Do not operate the generator in rain, snow, or wet weather.

n

Empty fuel tank, close fuel valve, and restrain the unit from

moving before transporting in a vehicle.

n

Allow engine to cool for five minutes before refueling.

n

To reduce the risk of fire and burn injury, handle fuel with

care. It is highly flammable.

n

Do not smoke while handling fuel.

n

Store fuel in a container approved for unleaded fuel.

n

Position the unit on level ground, stop engine, and allow

to cool before refueling.

n

Loosen fuel cap slowly to release pressure and to keep

fuel from escaping around the cap.

n

Tighten the fuel cap securely after refueling.

n

Wipe spilled fuel from the unit.

n

Never attempt to burn off spilled fuel under any

circumstances.

n

Use only authorised replacement parts and accessories

and follow instructions in the Maintenance section of this

manual. Use of unauthorised parts or failure to follow

Maintenance instructions may create a risk of shock or

injury.

n

Maintain the unit per maintenance instructions in this

Operator’s Manual.

n

Inspect the unit before each use for loose fasteners, fuel

leaks, etc. Replace damaged parts.

n

The generators vibrate in normal use. During and after

the use of the generator, inspect the generator as well as

extension cords and power supply cords connected to it

for damage resulting from vibration. Have damaged items

repaired or replaced as necessary. Do not use plugs or

cords that show signs of damage such as broken or cracked

insulation or damaged blades.

2

English

spECIfIC sAfETy RULEs

WARNING:

When this generator is used to supply a building

wiring system:

the generator must be installed by

a qualified electrician and connected to a transfer

switch as a separately derived system in accordance

with NFPA 70, National Electrical Code. The

generator shall be connected through a transfer

switch that switches all conductors other than the

equipment grounding conductor. Failure to isolate

the generator from power utility can result in death or

injury to electric utility workers.

n

Exhaust contains poisonous carbon monoxide, a

colorless, odorless gas. Breathing exhaust can cause

loss of consciousness and can lead to death. If running

in a confined or partially-enclosed area, the air may

contain a dangerous amount of carbon monoxide. To

keep exhaust fumes from building up, always provide

adequate ventilation.

n

Always use a battery-powered carbon monoxide

detector when running the generator. If you begin to feel

sick, dizzy, or weak while using the generator, shut it off

and get to fresh air immediately. See a doctor. You may

have carbon monoxide poisoning.

n

Place the generator on a flat, stable surface with a slope

of no more than 4°.

n

Operate in a well-ventilated, well-lit area isolated from

working areas to avoid noise interference.

n

Operating the generator in wet conditions could result in

electrocution. Keep the unit dry.

n

Keep the generator a minimum of 1m away from all

types of combustible material.

n

Do not operate the generator near hazardous material.

n

Do not operate the generator at a gas or natural gas

filling station.

n

Do not touch the muffler or cylinder during or

immediately after use; they are HOT and will cause burn

injury.

n

Do not connect to a building’s electrical system unless a

transfer switch has been properly installed by a qualified

electrician.

n

Do not allow the generator’s gas tank to overflow

when filling. Fill to 25mm below the top neck of the

unleaded fuel tank to allow for fuel expansion. Check the

ventilation hole inside the fuel tank cap for debris. Do not

block the vent.

n

Do not smoke when filling the generator with unleaded

fuel.

n

Allow the engine to remain in a shut-down condition for

at least five minutes before adding unleaded fuel or oil.

n

Do not remove the oil dipstick or the fuel tank cap when

the engine is running.

n

Pay close attention to all safety labels located on the

generator.

n

Keep children a minimum of 10 feet away from the

generator at all times.

n

The unit operates best in temperatures between 5°C and

40°C with a relative humidity of 30~95%.

n

Do not operate the generator at altitudes above 1000m.

n

When using extension lines or mobile distribution

networks the total length of lines for a cross section of

1.5mm

2

should not exceed 60m; for a cross section of

2.5mm

2

this should not exceed 100m.

n

The generating set must not be connected to other

power sources

n

Save these instructions. Refer to them frequently and use

them to instruct others who may use this tool. If you loan

someone this tool, loan them these instructions also.

3

English

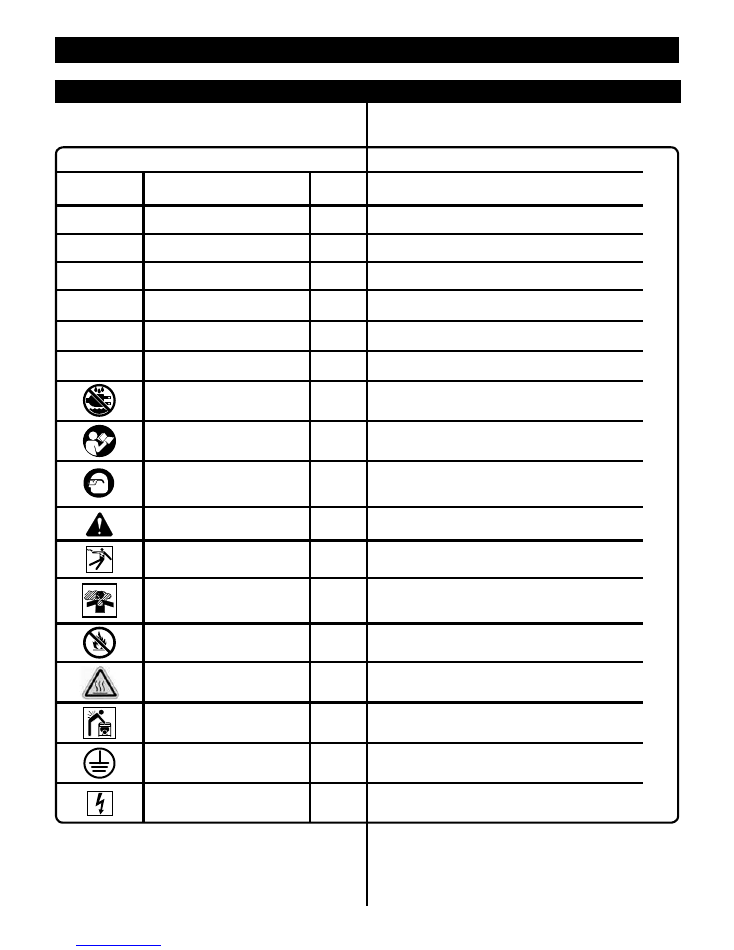

symBOLs

Some of the following symbols may be used on this tool. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and safer.

symBOL

NAmE

DEsIGNATION/EXpLANATION

V

Volts

Voltage

A

Amperes

Current

Hz

Hertz

Frequency (cycles per second)

W

Watt

Power

hrs

Hours

Time

gal

Gallon

Volume

qt

Quart

Volume

Wet Conditions Alert

Do not expose to rain or use in damp locations.

Read The Operator’s Manual

To reduce the risk of injury, the user must read and understand

the operator’s manual before using this product.

Eye Protection

Always wear safety goggles or safety glasses with side shields

and, as necessary, a full face shield when operating this product.

Safety Alert

Precautions that involve your safety.

Electric Shock

Failure to use in dry conditions and to observe safe practices

can result in electric shock.

Toxic Fumes

Running the generator gives off carbon monoxide, an odorless,

colorless, poison gas. Breathing carbon monoxide can cause

nausea, fainting, or death.

Fire/Explosion

Fuel and its vapors are extremely flammable and explosive. Fire

or explosion can cause severe burns or death.

Hot Surface

To reduce the risk of injury or damage, avoid contact with any

hot surface.

Lifting Hazard

To reduce the risk of serious injury, avoid attempting to lift the

generator alone.

Ground

Consult with local electrician to determine grounding

requirements before operation.

Electrocution

Failure to properly ground generator can result in electrocution,

especially if the generator is equipped with a wheel kit.

4

English

5

English

6

English

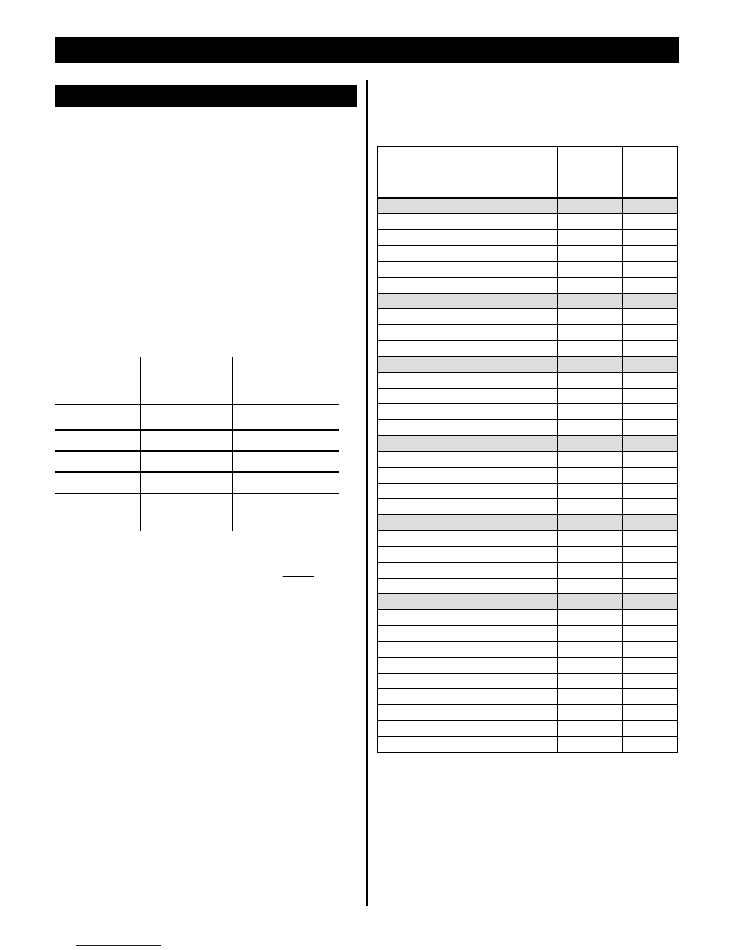

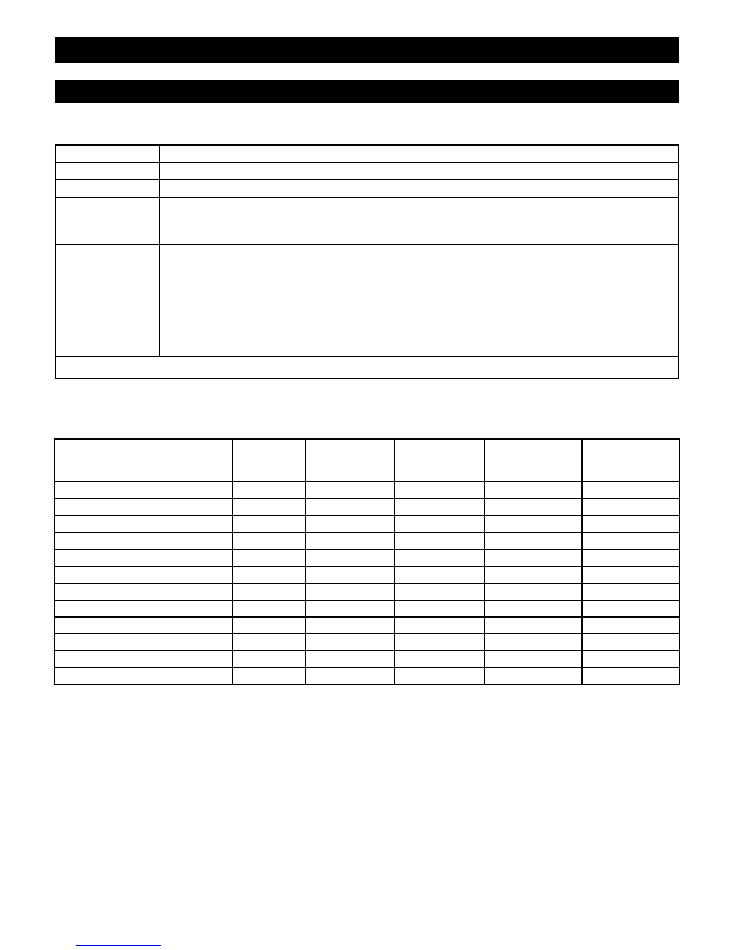

ELECTRICAL

GENERATOR CApACITy

Make sure the generator can supply enough continuous (running)

and surge (starting) watts for the items you will power at the

same time. Follow these simple steps.

1. Select the items you will power at the same time.

2. Total the continuous (running) watts of these items. This

is the amount of power the generator must produce to

keep the items running. See the wattage reference chart

at right.

3. Estimate how many surge (starting) watts you will need.

Surge wattage is the short burst of power needed to start

electric motor-driven tools or appliances such as a circular

saw or refrigerator. Because not all motors start at the

same time, total surge watts can be estimated by adding

only the item(s) with the highest additional surge watts to

the total rated watts from step 2.

Example:

Tool or

Appliance

Continuous

(Running)

Watts

Surge

(Starting) Watts

CD Player

100

0

Space Heater

1800

0

Drill

500

0

Light (75 Watts)

75

75

2475 Total

Running Watts

75 Highest Surge

Watts

Total Continuous (Running) Watts

2475

Plus Highest Additional Surge Watts

+ 75

Equals Total Generator Output Required

2550

pOWER mANAGEmENT

To prolong the life of the generator and attached devices, it

is important to take care when adding electrical loads to the

generator. There should be nothing connected to the generator

outlets before starting its engine. The correct and safe way to

manage generator power is to sequentially add loads as follows:

1. With nothing connected to the generator, start the engine

as described later in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilise (engine runs

smoothly and attached device operates properly).

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilise.

6. Repeat steps 4 and 5 for each additional load.

Never add more loads than the generator capacity. Take

special care to consider surge loads in generator capacity as

previously described.

CAUTION:

Do not overload the generator’s capacity. Exceeding the

generator’s wattage/amperage capacity can damage the

generator and/or electrical devices connected to it.

Tool or Appliance

Typical

Continuous*

(Running)

Watts

Typical

surge

(starting)

Watts

Essentials

Light Bulb − 75 Watt

75

75

Refrigerator/Freezer

700

2200

Sump Pump − 1/2 HP

1050

2200

Water Well Pump − 1/3 HP

1000

1500

Electric Water Heater

4000

0

Heating/Cooling

Furnace Fan − 1/2 HP

800

2350

Window AC − 10,000 BTU

1200

1800

Space Heater

1800

0

Kitchen

Microwave Oven − 1000 Watt

1000

0

Coffee Maker

1000

0

Electric Stove − Single Element

2100

0

Toaster Oven

1200

0

family Room

VCR

100

0

CD/DVD Player

100

0

Stereo Receiver

450

0

Colour Television − 27 in.

500

0

Other

Security System

500

0

Curling Iron

1500

0

Garage Door Opener − 1/2 HP

875

2350

Hair Dryer − 1/2 HP

1250

0

DIy/Job site

Quartz Halogen Work Light

1000

0

Airless Sprayer − 1/3 HP

600

1200

Reciprocating Saw

960

0

Electric Drill − 1/2 HP

600

900

Circular Saw − 7-1/4 in.

1400

2300

Miter Saw − 10 in.

1800

1800

Planer/Jointer − 6 in.

1800

1800

Table Saw/Radial Arm Saw − 10 in.

2000

2000

Air Compressor − 1 HP

1600

4500

*Wattages listed are approximate. Check tool or appliance for actual wattage.

7

English

fEATUREs

model

AGN2400B

AC Output

AC Frequency (Hz)

50

AC Output voltage (V)

230

Rated AC Output (W)

2,000

Rated Current (A)

8.7

Circuit Breaker (A)

9

Power Factor

1.0

DC Output

Volts

12

Amps

8.3

Engine

Engine Number

UP168

Engine Type

4-Stroke; air-cooled OHV; Gasoline

Bore x Stroke

68x45

Displacement (cc)

163

Starting System

recoil

Fuel Type

Unleaded fuel

Lubrication oil

SAE 10W/30

Engine Oil Volume(L)

0.6 L

Fuel Tank Capacity (l)

15

Max. Output (hp)

5.5

Max Output (rpm)

3,600

Full Load (h)

11

Half Load (h)

20.0

Approvals

CE

Yes

Euro Emission

Yes

4m Noise Level LpA dB (A)

75

4m Noise Level LwA dB (A)

95

Uncertainty dB (A)

2

7m Noise Level LpA dB (A)

70

7m Noise Level LwA dB (A)

90

8

English

fEATUREs

KNOW yOUR GENERATOR

See Figure 3.

The safe use of this product requires an understanding of the

information on the product and in this operator’s manual as well

as a knowledge of the project you are attempting. Before use

of this product, familiarise yourself with all operating features

and safety rules.

AC CIRCUIT BREAKER

The circuit breaker is provided to protect the generator against

electrical overload and can be used to turn the generator’s

electrical power on or off.

AIR fILTER

The air filter helps to limit the amount of dirt and dust drawn

into the unit during operation.

CHOKE LEVER

The choke lever is used when starting the engine.

ENGINE sWITCH

The engine switch is used in combination with the recoil starter

grip to start the generator. It is also used to turn the generator off.

fUEL LEVEL GAUGE

Consult the fuel level gauge to determine the amount of fuel

remaining in the generator.

fUEL TANK

15 litres

fUEL VALVE

The flow of fuel through the generator is controlled by the

position of the fuel valve.

GROUND TERmINAL

The ground terminal is used to assist in properly grounding

the generator to help protect against electrical shock. Consult

with a local electrician for grounding requirements in your area.

OIL DRAINAGE BOLT

When changing the engine oil, the oil drainage bolt is loosened

to allow old engine oil to be drained.

OIL CAp/DIpsTICK

Remove the oil fill cap to check and add oil to the generator

when necessary.

RECEpTACLEs

Your generator has the following single phase, 50 Hz outlets:

one 230 Volt AC, 16 Amp receptacle. These can be used for

operating appropriate appliances, electrical lighting, tools, and

motor loads.

RECOIL sTARTER GRIp

The recoil starter grip is used (along with the engine switch) to

start the generator’s engine.

DC TERmINALs

The DC terminals may ONLY be used for charging 12 volt

automotive type batteries.

The terminals are colored red to identify the positive (+) terminal

and black to identify the negative (-) terminal. The battery must

be connected to the generator DC terminals with the proper

polarity ( battery positive to generator red terminal and battery

negative to the generator black terminal).

DC CIRCUIT pROTECTOR

The DC circuit protector automatically shuts off the DC battery

charging circuit when the DC charging circuit is overloaded, when

there is a problem with the battery, or when the connections

between the battery and the generator are improper.

AssEmBLy

UNpACKING

This product has been shipped completely assembled.

n

Remove one end of the box and carefully slide out the

generator and any accessories.

NOTE:

The generator is heavy. If you must lift the unit out

of the box, get another person to help you and lift with your

legs, not your back.

n

Inspect the unit carefully to make sure no damage occurred

during shipping.

n

Do not discard the packing material until you have carefully

inspected and satisfactorily operated the product.

n

If any parts are damaged or missing, please contact your

nearest authorised service centre for assistance.

pACKING LIsT

Generator

Spark Plug Wrench

Oil Bottle / Oil Funnel

Handle and wheels

Operator’s Manual

9

English

WARNING:

If any parts are damaged or missing do not operate

this product until the parts are replaced. Failure to

heed this warning could result in serious personal

injury.

WARNING:

Do not attempt to modify this tool or create

accessories not recommended for use with this

tool. Any such alteration or modification is misuse

and could result in a hazardous condition leading to

possible serious personal injury.

OpERATION

DANGER:

Carbon monoxide.

Using a generator indoors WILL

KILL YOU IN MINUTES.

Generator exhaust contains high levels of carbon monoxide

(CO), a poisonous gas you cannot see or smell. If you can

smell the generator exhaust, you are breathing CO. But even

if you cannot smell the exhaust, you could be breathing CO.

n

Never use a generator inside homes, garages,

crawlspaces, or other partly enclosed areas. Deadly

levels of carbon monoxide can build up in these areas.

Using a fan or opening windows and doors does NOT

supply enough fresh air.

n

ONLY use a generator outdoors and far away from open

windows, doors, and vents. These openings can pull in

generator exhaust.

Even when you use a generator correctly, CO may leak into

the home. ALWAYS use a battery-powered or battery-backup

CO alarm in the home.

If you start to feel sick, dizzy, or weak after the generator has

been running, move to fresh air RIGHT AWAY. See a doctor.

You could have carbon monoxide poisoning.

DANGER:

Failure to properly ground generator can result in

electrocution, especially if the generator is equipped

with a wheel kit. Generators have to be properly

grounded to an approved earth ground. Call an

electrician for local grounding requirements.

WARNING:

Do not allow familiarity with tools to make you

careless. Remember that a careless fraction of a

second is sufficient to inflict serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product.

The use of attachments or accessories not

recommended can result in serious personal injury.

AppLICATIONs

This generator is designed to supply electrical power for

operating compatible electrical lighting, appliances, tools,

and motor loads.

BEfORE OpERATING THE UNIT

Position the generator on a flat surface before checking fluid

levels or adding fluid.

CAUTION:

Attempting to start the engine before it has been

properly filled with oil will result in equipment failure.

CHECKING/ADDING OIL

See Figure 4.

Engine oil has a major influence on engine performance and

service life. For general, all-temperature use, SAE 10W-40 is

recommended. Always use a 4-stroke motor oil that meets or

exceeds the requirements for API service classification SJ.

NOTE:

Non-detergent or 2-stroke engine oils will damage

the engine and should not be used.

n

Unscrew the oil cap/dipstick and remove.

n

Wipe dipstick clean and re-seat in hole; do not re-thread.

n

Remove dipstick again and check oil level. Oil level

should fall within the level indicator area on the dipstick.

n

If level is low, add engine oil until the fluid level rises

to the upper portion of the level indicator area on the

dipstick.

n

Replace and secure the oil cap/dipstick.

CHECKING/ADDING fUEL

See Figure 5.

n

Check the fuel level gauge. If fuel is needed, continue

with the next step.

n

Remove the fuel cap.

n

Fill the fuel tank to 25mm below the top of the fuel neck.

n

Replace and secure the fuel cap.

NOTE:

Always use unleaded gasoline with a pump octane

rating of 86 or higher. Never use old, stale, or contaminated

unleaded fuel, and do not use an oil/gas mixture. Do not allow

dirt or water into the fuel tank.

10

English

UsING fUEL sTABILIsER

Fuel gets old, oxidizes, and breaks down over time. Adding a

fuel stabiliser extends the usable life of fuel and helps prevent

deposits from forming that can clog the fuel system. Follow

fuel stabiliser manufacturer’s directions for correct ratio of

stabiliser to fuel.

n

Add stabiliser to fuel tank, then fill with unleaded fuel

following previous instructions.

NOTE:

Fuel stabiliser and unleaded fuel can be mixed

prior to filling the tank by using a gas can or other

approved fuel container and shaking gently to combine.

n

Replace and secure the fuel tank cap.

n

Start and run the engine for at least 5 minutes to allow

stabiliser to treat the entire fuel system.

OXyGENATED fUELs

DO NOT UsE E85 fUEL. IT WILL VOID yOUR

WARRANTy.

NOTE:

Some conventional petrol are blended with alcohol or

an ether compound. This type of petrol is collectively referred

to as oxygenated fuel; in Australia known as Ethanol. The use

of ethanol fuel, or fuels containing ethanol is not recommended

for this product.

CAUTION:

On a level surface with the engine off, check the oil

level before each use of the generator.

AC OpERATION

n

Unplug all loads from the generator.

n

Switch the AC circuit breakers to the OFF (O) position.

n

Start the engine (refer to "STARTING THE ENGINE"

section. (later on this page)

n

Switch the AC circuit breakers to the ON ( I ) position.

n

Plug in the appliance.

DC OpERATION

The DC terminals may ONLY be used for charging 12 volt

automotive type batteries.

CAUTION:

The battery gives off explosive gases; keep

sparks, flames and cigarettes away. provide

adequate ventilation when charging or using

batteries.

CAUTION:

Battery posts, terminals and related accessories

contain lead and lead compounds. Wash hands

after handling.

Connecting the battery cables:

n

Before connecting the battery charging cables to

a battery that is installed in a vehicle, disconnect the

vehicle ground battery cable from the battery negative (-)

terminal.

n

Connect the positive (+) battery cable to the battery

positive (+) terminal.

n

Connect the other end of the positive (+) battery cable to

the generator positive (+) terminal.

n

Connect the negative (-) battery cable to the battery

negative (-) terminal.

n

Connect the other end of the negative (-) battery cable to

the generator negative (-) terminal.

n

Start the engine. (refer to "STARTING THE ENGINE"

section)

NOTE:

Do not start the vehicle while the battery charging

cable is connected and the generator is running. The

vehicle or the generator may be damaged.

An overloaded DC circuit, excessive current draw by the battery,

or a wiring problem will trip the DC circuit protector (PUSH

button extends out). If this happens, wait a few minutes before

pushing in the circuit protector to resume operation. If the DC

circuit protector continues to go OFF, discontinue charging and

see your nearest authorised service centre.

Disonnecting the battery cables:

n

Disconnect the negative (-) battery cable from the

generator negative (-) terminal.

n

Disconnect the other end of the negative (-) battery cable

from the battery negative (-) terminal.

n

Disconnect the positive (+) battery cable from the

generator positive (+) terminal.

n

Connect the other end of the positive (+) battery cable to

the battery positive (+) terminal.

n

Reconnect the vehicle ground battery cable to the battery

negative (-) terminal.

sTARTING THE ENGINE

See Figures 6 - 8.

NOTE:

If location of generator is not level, the unit may not

start or may shut down during operation.

n

Turn the fuel valve to the ON position.

n

Move the choke lever to the START position.

NOTE:

If engine is warm or the temperature is above

10˚C, push the choke lever in to the RUN position.

n

Put the engine switch in the ON ( I ) position.

n

Pull the recoil starting grip until the engine runs (a

maximum of 6 times).

NOTE:

Do not allow the grip to snap back after starting;

return it gently to its original place.

n

Allow the engine to run for 30 seconds, then move the

choke lever in to the RUN position.

11

English

sTOppING THE ENGINE

See Figures 6- 7.

To stop the engine under normal operating conditions:

n

Remove any load from the generator.

n

Switch the AC circuit breakers to the OFF position.

n

Disconnect DC battery charging cables.

n

Turn the fuel valve to the OFF position.

n

Put the engine switch in the OFF ( O ) position.

n

Turn the key to "OFF" position (Electric start only).

To stop the engine in an emergency situation:

n

Put the engine switch in the OFF ( O ) position.

mAINTENANCE

WARNING:

When servicing, use only identical Ryobi

replacement parts. Use of any other parts may

create a hazard or cause product damage.

Only the parts shown on the parts list are intended to be repaired

or replaced by the customer. All other parts should be replaced

at an authorised service centre.

GENERAL mAINTENANCE

Keep the generator in a clean and dry environment where it is

not exposed to dust, dirt, moisture, or corrosive vapors. Do not

allow the cooling air slots in the generator to become clogged

with foreign material such as leaves, snow, etc.

Do not use a garden hose to clean the generator. Water entering

the fuel system or other internal parts of the unit can cause

problems that will decrease the life of the generator.

To clean the unit:

n

Use a soft bristle brush and/or vacuum cleaner to loosen

and remove dirt and debris.

n

Clean air vents with low pressure air that does not

exceed 25 psi.

n

Wipe the exterior surfaces of the generator with a damp

cloth.

CHECKING/CLEANING AIR fILTER

See Figure 9.

For proper performance and long life, keep air filters clean.

n

Lift the latches located at the top and bottom of the air

filter cover. Remove the cover and set aside.

n

Remove the filter elements.

n

If the filter elements are dirty, clean with warm, soapy

water. Rinse and let dry.

n

Apply a light coat of engine oil to the elements, then

squeeze it out.

n

Replace the elements in the air filter unit.

n

Replace the air filter cover and close latches to secure.

NOTE:

Do not run the generator without the air filter.

Rapid engine wear will result.

CHANGING ENGINE OIL

See Figure 10.

n

Remove the oil cap/dipstick.

n

Place a container underneath the oil drainage bolt to

collect used oil as it drains.

n

Unscrew the oil drainage bolt and remove.

n

Allow oil to drain completely.

n

Reinstall the oil drainage bolt and tighten securely.

n

Refill with oil following the instructions in the

Checking/

Adding Oil

section.

n

Reinstall the oil cap/dipstick.

NOTE:

Used oil should be disposed of at an approved

disposal site. See your local oil retailer for more information.

CLEANING fUEL sEDImENT CUp

See Figure 11.

The sediment cup prevents dirt and water that may have gotten

into the fuel tank from entering the carburetor. If the engine

has not been run for a long time, the sediment cup should be

cleaned before use.

n

Turn the fuel valve to the OFF position.

n

Remove the sediment cup using a 10 mm wrench (not

provided).

n

Remove the O-ring and filter.

n

Clean each of the parts in carburetor cleaner or any

comparable cleaning product.

n

Reinstall the filter, O-ring, and sediment cup. Tighten with

wrench to secure.

n

Return the fuel valve to ON position and check for leaks.

spARK pLUG mAINTENANCE

See Figure 12.

The spark plug must be properly gapped and free of deposits

in order to ensure proper engine operation. To check:

n

Remove the spark plug cap.

n

Clean any dirt from around base of spark plug.

n

Remove spark plug using wrench provided.

n

Inspect spark plug for damage, and clean with a wire

brush before reinstalling. If insulator is cracked or

chipped, spark plug should be replaced.

NOTE:

If replacing, use the following recommended

spark plugs or equivalent: Champion RN11YC or NGK

BPR6ES.

n

Seat spark plug in position; thread in by hand to prevent

cross-threading.

n

Tighten with wrench to compress washer. If spark plug

is new, use 1/2 turn to compress washer appropriate

amount. If reusing old spark plug, use 1/8 to 1/4 turn for

proper washer compression.

NOTE:

An improperly tightened spark plug will become

very hot and could damage the engine.

12

English

CLEANING THE EXHAUsT pORT AND mUffLER

Depending on the type of fuel used, the type and amount of

oil used, and/or your operating conditions, the exhaust port

and muffler may become blocked with carbon deposits. If

you notice a power loss with your petrol-powered tool, you

may need to remove these deposits to restore performance.

We highly recommend that only qualified service technicians

perform this service.

spARK ARREsTOR

Product users in some areas, must comply with fire prevention

regulations. This product is equipped with a spark arrestor.

DRAINING fUEL TANK / CARBURETOR

When not using a fuel stabiliser, draining the fuel from the tank

and carburetor before storage may help prevent gum deposits

in the fuel system.

DRAINING THE fUEL TANK

See Figure 13.

n

Turn the engine switch OFF ( O ).

n

Close fuel valve.

n

Remove the fuel line from the barb by squeezing the

ends of the retaining clip and sliding the fuel line off.

n

Install one end of a drain line over the barb, and place

the other end in a fuel container large enough to catch

the fuel being drained from the tank.

n

Open fuel valve.

n

When the fuel has drained from the tank, close the fuel

valve and reinstall fuel line on barb.

DRAINING THE CARBURETOR

See Figure 2.

n

Turn the engine switch off ( O ).

n

Close the fuel valve.

n

Position an approved fuel container under the carburetor

drain screw to catch fuel; loosen the screw.

n

Allow fuel to drain completely into container.

n

Retighten drain screw.

NOTE:

After draining the fuel tank and carburetor, start

the engine and allow it to run until the unit runs out of

fuel. Consult hazardous waste management guidelines in

your area for the proper way to dispose of used fuel.

TRANspORTING

n

Turn engine switch OFF ( O ).

n

Close the fuel valve.

n

Make sure engine and exhaust of unit is cool.

n

Keep unit level to prevent fuel spillage.

n

Do not drop or strike unit or place under heavy objects.

13

English

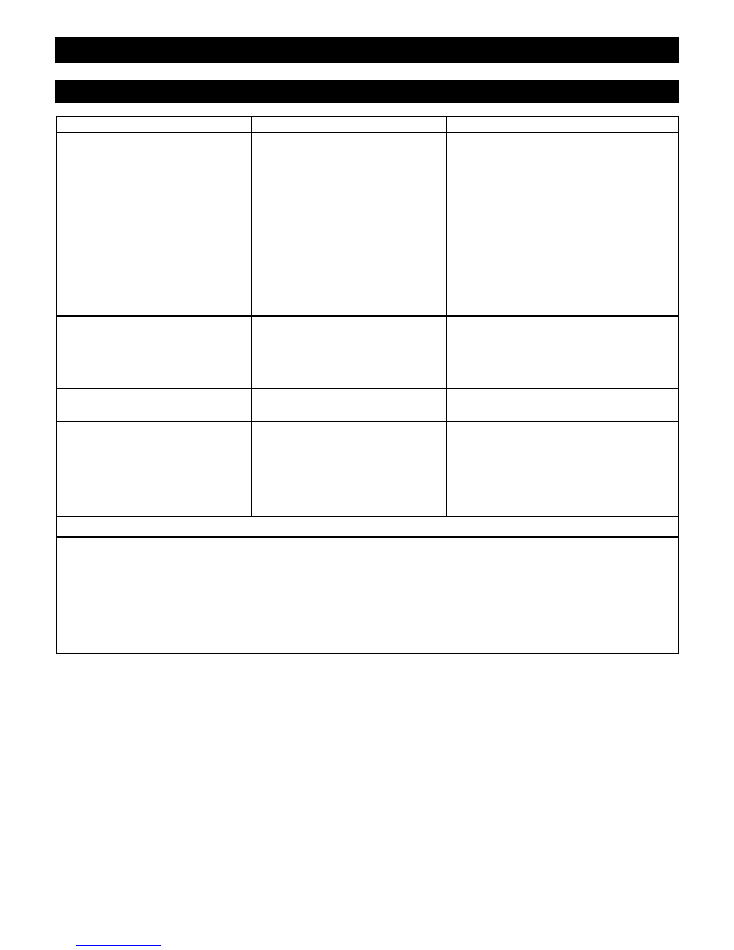

mAINTENANCE

sTORAGE

When preparing the generator for storage, follow the guidelines below.

sTORAGE TImE

pRIOR TO sTORING

Less than 1 month

n

No special preparation is required.

1 to 2 months

n

Empty fuel from fuel tank.

2 months to 1 year

n

Empty fuel from fuel tank.

n

Drain fuel from carburetor.

n

Clean fuel sediment cup.

1 year or more

n

Empty fuel from fuel tank.

n

Drain fuel from the carburetor.

n

Clean fuel sediment cup.

n

Remove spark plug.

n

Put a tablespoon of engine oil into the spark plug cylinder. Turn the engine slowly with the pull rope to

distribute the oil.

n

Reinstall spark plug.

n

Change engine oil.

*Use unleaded fuel stabilisers formulated to extend storage life. For recommendations, contact your nearest authorized service center.

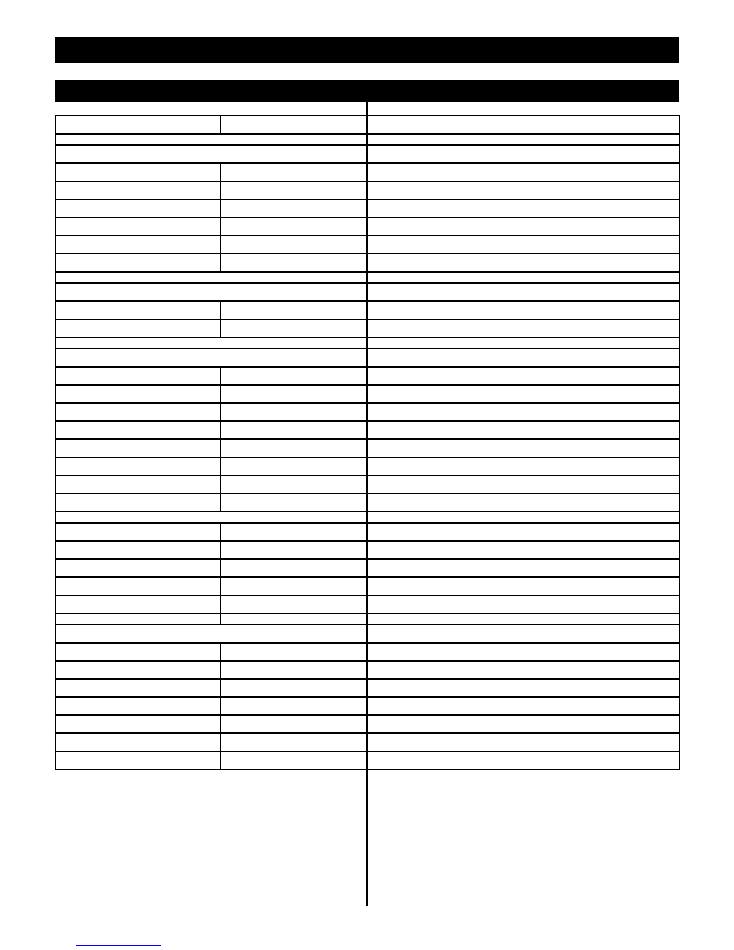

mAINTENANCE sCHEDULE

Before

each use

After 1st month

or 20 hours of

operation

Every 3 months

or 50 hours of

operation

Every 6 months

or 100 hours

of operation

Every year or

after 300 hours

of operation

Check Engine Oil

n

Change Engine Oil

n

n

Check Air filter

n

Clean Air filter

n

Change Air filter

n

Clean Carburetor sediment Cup

n

Check/Adjust spark plug

n

Replace spark plug

n

Check/Adjust Idle speed

n

Check/Adjust Valve Clearance*

n

Clean fuel Tank and filter*

n

Check fuel Tube

n

* These items should only be carried out by an authorized service center.

NOTE:

Maintenance should be performed more frequently when generator is used in dusty areas.

When generator has exceeded the maximum figures specified in the table, maintenance should still be cycled according to

the intervals of time or hours stated herein.

14

English

mAINTENANCE

pROBLEm

pOssIBLE CAUsE

sOLUTION

Engine will not start.

Engine switch is OFF.

No fuel.

Oil level is low.

Fuel valve is OFF.

Spark plug faulty, fouled, or improperly

gapped.

Fuel is not reaching carburetor.

Choke is OPEN.

Engine stored without treating or draining

unleaded fuel, or refueled with bad

unleaded fuel.

Turn engine switch to ON.

Fill fuel tank.

Check engine oil level and fill, if necessary.

Turn fuel valve ON.

Replace spark plug.

Clean fuel sediment cup.

Move choke lever out to START.

Drain fuel and carburetor. Refuel with fresh

unleaded fuel.

Engine lacks power.

Fuel element clogged.

Engine stored without treating or draining

unleaded fuel, or refueled with bad

unleaded fuel.

Check air filter element. Clean or replace as

needed.

Drain fuel and carburetor. Refuel with fresh

unleaded fuel.

AC receptacle does not work.

Circuit breaker is OFF.

Item plugged in is defective.

Turn ON the AC circuit breaker.

Try a different item.

Generator makes a “spark knock” or

“pinging” noise.

An occasional light “knocking” or

“pinging” under heavy load is not a cause

for concern. However, if the knocking

or pinging occurs under normal load

at a steady engine speed, the problem

may be with the brand of unleaded fuel

being used.

Switch to a different brand of unleaded fuel,

making sure that the octane rating is 86 or

higher. If problem continues, contact your nearest

authorized service center.

If problem persists after trying the above solutions, contact your nearest authorized service center for assistance.

The following symptoms may indicate problems that will affect the emissions level of the unit:

n

Hard starting or stalling after starting

n

Rough idle

n

Misfiring or backfiring under load

n

Afterburning (backfiring)

n

Black exhaust smoke or high fuel consumption

If you encounter any of these symptoms, have the unit inspected and repaired by the nearest authorized service center.

15

English

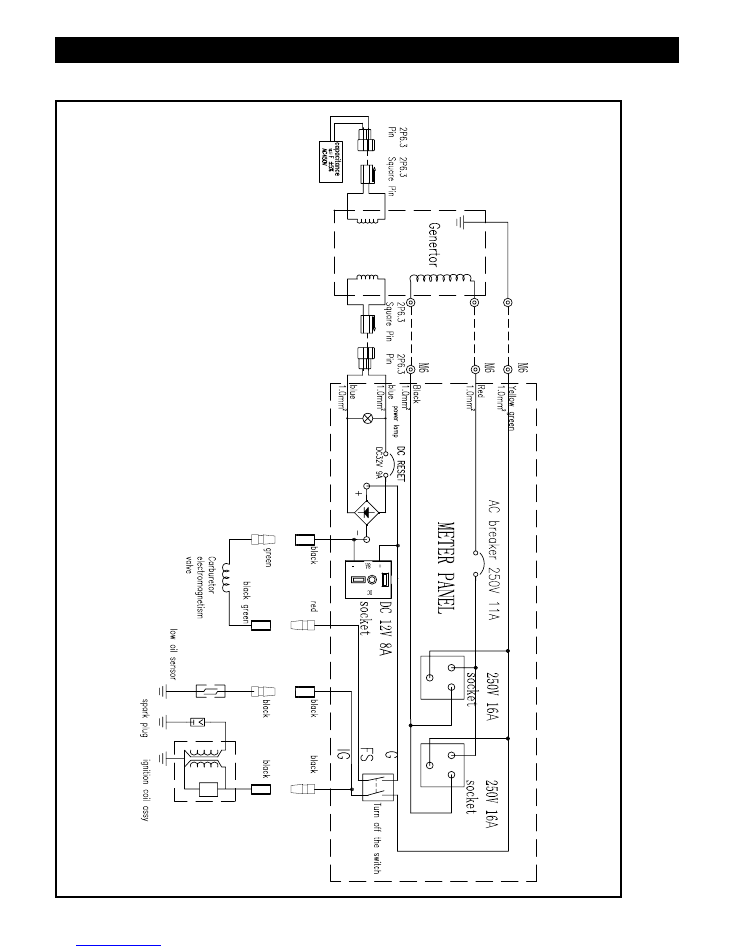

WIRING DIA

GRAM

- A

GN2400B

LImITED WARRANTy

TTI warrants this outdoor product to be free of defects in material and workmanship for 24 months from the date of purchase by the original purchaser,

subject to the limitations below. Please keep your invoice as proof of date of purchase.

This warranty is only applicable where the product is used for personal and non-commercial purposes.

This warranty does not cover damage

or liability caused by / due to misuse, abuse, accidental or intentional acts by user, improper handling, unreasonable use, negligence, failure by end

user to follow operating procedures outlined in the user’s manual, attempted repair by non-qualified professional, unauthorized repair, modification, or

use of accessories and/or attachments not specifically recommended by authorized party. Please see your local dealer for list of authorized service

centers in your area.

This warranty does not cover belts, brushes, bags, bulbs or any part which ordinary wear and tear results in required replacement during warranty

period. This warranty does not cover transportation cost or consumable items such as fuses and batteries.

This limited warranty is void if the product’s original identification (trade mark, serial number, etc.) markings have been defaced, altered or removed or if

product is not purchased from an authorized reseller or if product is sold AS IS and / or WITH ALL FAULTS.

Where permitted, the provisions of this limited warranty are in lieu of any other written warranty, whether express or implied, written or oral, including

any warranty of MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL WE BE LIABLE FOR SPECIAL,

INCIDENTAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES. OUR MAXIMUM LIABILITY SHALL NOT EXCEED THE ACTUAL PURCHASE

PRICE PAID BY YOU FOR THE PRODUCT.

This warranty is applicable only in the European Union, Australia, and New Zealand. Outside these areas, please contact your authorized

Homelite dealer to determine if another warranty applies.

Technical documents are kept by Homelite Far East Co., Ltd. 24/F, 388 Castle Peak Road, Tsuen Wan, N.T., Hong Kong.Declared in 09/2008 by

Homelite Far East Co., Ltd.

The figures quoted are emission levels and are not necessarily safe working levels. Whilst there is a correlation between the emission and exposure

levels, this cannot be used reliably to determine whether or not further precautions are required. Factors that influence the actual level of exposure of

work-force include the characteristics of the work room, the other sources of noise, etc. i.e. the number of machines and other adjacent processes,

and the length of time for which an operator is exposed to the noise. Also the permissible exposure level can vary from country. This information,

however, will enable the user of the machine to make a better evaluation of the hazard and risk.

Machine:

portable Generator set

Name of company: Homelite Far East Co., Ltd.

Address:

24/F, CDW Building,

388 Castle Peak Road,

Tsuen Wan Hong Kong.

RyOBI TECHNOLOGIEs (UK) LImITED

Medina House,

Fieldhouse Lane, Marlow,

Buckinghamshire,

SL7 1TB,

UNITED KINGDOM

Tel: + 44 (0)1628 894400

Fax: +44 (0)1628 894401

Technical helpline: +44 (0) 800 3890305

RyOBI TECHNOLOGIEs sAs

Immeuble Le Grand Roissy

Z.A. du Gué - 35 rue de Guivry

77990 LE MESNIL AMELOT FRANCE

Phone: + 33 (0)1 60 94 69 70

Fax: + 33 (0)1 60 94 69 79

RyOBI BELGIUm

Avenue des Pâquerettes, 55

Zoning artisanal - bâtiment 5

B - 1410 Waterloo

BELGIQUE

Tel : + 32 (0) 2 357 81 40

Fax : + 32 (0) 2 357 81 49

RyOBI ITALIA

Via Vincenzo Borelli, 13

I - 41100 Modena

ITALIA

Tel : + 39 (0) 59 23 84 08

Fax : + 39 (0) 59 24 69 60

RyOBI IBÉRICA

Avenidad de la Industria 52

28820 Coslada - Madrid

ESPANA

Tel : + 34 (0) 91 627 93 26

Fax : + 34 (0) 91 627 93 29

TECHTRONIC INDUsTRIEs (AsIA) CO. LTD

24/F, CDW Building,

388 Castle Peak Road,

Tsuen Wan, Hong Kong.

Tel : + 852 2402 6888

RyOBI TECHNOLOGIEs GmBH

Itterpark 4

D-40724 Hilden

DEUTSCHLAND

Tel: + 49 (0) 2103 2958-0

Fax: + 49 (0) 2103 2958-29

RyOBI TECHNOLOGIEs GmBH

Vertriebsbüro Österreich

Schinitzgasse 13

A-8605 Kapfenberg

Tel.: + 43 (0) 3862 23590-0

Fax: + 43 (0) 3862 23590-25

TECHTRONIC INDUsTRIEs

AUsTRALIA pTy LImITED

Building B, Rosehill Industrial Estate,

3 Shirley Street,

Rosehill NSW 2142

AUSTRALIA

Tel: (02) 8892 1800 or 1300 361 505

Fax: 1800 807 993

TECHTRONIC INDUsTRIEs (NZ) LImITED

27 Clemow Drive, Mt Wellington

PO Box 12-806, Penrose, Auckland

NEW ZEALAND

Tel: + 64 (0) 9 573 0230 Free Call: +64 0800 279 624

Fax: + 64 (0) 9 573 0231

A&m mIDDLE EAsT fZCO

P.O.Box 61254

Jedel Ali, Dubai,

UNITED ARAB EMIRATES

Tel.: + 971 4 8861399

Fax: + 971 4 8861400

TECHTRONIC INDUsTRIEs NORDIC

Stamholmen 147, 4. DK-2650 Hvidovre

DENMARK

Tel.: (+45) 43 56 55 55

Fax: (+45) 43 56 55 56

Type: AGN2400B

Name / title: Sven Eschrich

Director of Engineering

Signature:

1 / 2010