Full Text Searchable PDF User Manual

150 PSI 6 CFM M

odel

12V6CF

Serial No. ___________________

____

Questions?

As a manufacturer, we are com-

mitted to providing you complete

customer satisfaction. If you have

questions, or find there are missing

or damaged parts, we will guaran-

tee you complete satisfaction. To

avoid unnecessary delays, contact

your dealer immediately

CAUTION:

Read all safety precautions and

instructions in the manual carefully

OWNER’S MANUAL

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

WARRANTY

Voltair, Inc. warrants the Voltair against defective workmanship and parts in accordance with the warranty given to

us by our suppliers for one full year. If during the warranty period it is thought that the unit becomes inoperative

due to a defect, the Voltair needs to be returned to the dealer to determine the proper course of action. The dealer

shall contact Voltair, Inc. regarding a warranty inspection or replacement. Voltair, Inc. reserves the right to void

any warranty claim if the Voltair has been altered, shows bad maintenance, shows abuse, or has been dismantled

without proper authorization. Voltair, Inc. can request that the unit be returned for inspection. Voltair will not war-

ranty and is not liable for improper installation. Improper installation can be the result of poor judgment in running

power to the compressor, not installing a circuit breaker or not using a DOT approved air storage tank.

VOLTAIR, INC. IS NOT RESPONSIBLE OR LIABLE FOR INDIRECT, SPECIAL OR CONSEQUENTIAL DAM-

AGES ARISING OUT OF OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE PRODUCT

OR OTHER DAMAGES WITH RESPECT TO ANY ECONOMIC LOSS, LOSS OF PROPERTY, LOSS OF REV-

ENUES OR PROFITS, LOSS OF ENJOYMENT OR USE, COSTS OF REMOVAL, INSTALLATION OR OTHER

CONSEQUENTIAL DAMAGES OF WHATSOEVER NATURE.

Voltair, Inc., Henderson, NE

TABLE OF CONTENTS

WARNING

:

Please read through these instructions before installing the 12-Voltair air compressor

IMPORTANT SAFETY PRECAUTIONS ................................................................................................. 4

BEFORE YOU BEgIN

PICTURE DIAgRAM ...................................................................................................................5

INSTALLATION

ASSEMBLY .................................................................................................................................. 6

OIL ................................................................................................................................................. 6

FINDINg A LOCATION FOR THE 12-VOLTAIR .......................................................................7

DRILLINg/SECURINg ................................................................................................................7

ELECTRICAL

gROUND WIRE, POSITIVE WIRE ............................................................................. 8

BATTERY FACTS

(helping you pick the best battery for you)

.......................................... 8

TOggLE SWITCH (OPTIONAL) .................................................................................. 9

CIRCUIT BREAkER (OPTIONAL) ............................................................................... 9

PLUMBINg AIR STORAgE TO YOUR COMPRESSOR

CHOOSINg THE RIgHT SIzE AIR TANk .................................................................. 10

FINDINg A LOCATION FOR AN AIR TANk ............................................................... 10

OPERATION AND ADJUSTMENT .......................................................................................................... 11

MAINTENANCE ........................................................................................................................................ 11

WIRINg DIAgRAM ................................................................................................................................... 12

TROUBLESHOOTINg .............................................................................................................................. 13

WARRANTY CARD .................................................................................................................................. 15

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page

IMPORTANT SAFETY PRECAUTIONS

WARNING:

To reduce the risk of burns, fire, electric shock, or injury to persons, read the following important safety

precautions and information before operating this air compressor.

1.

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page

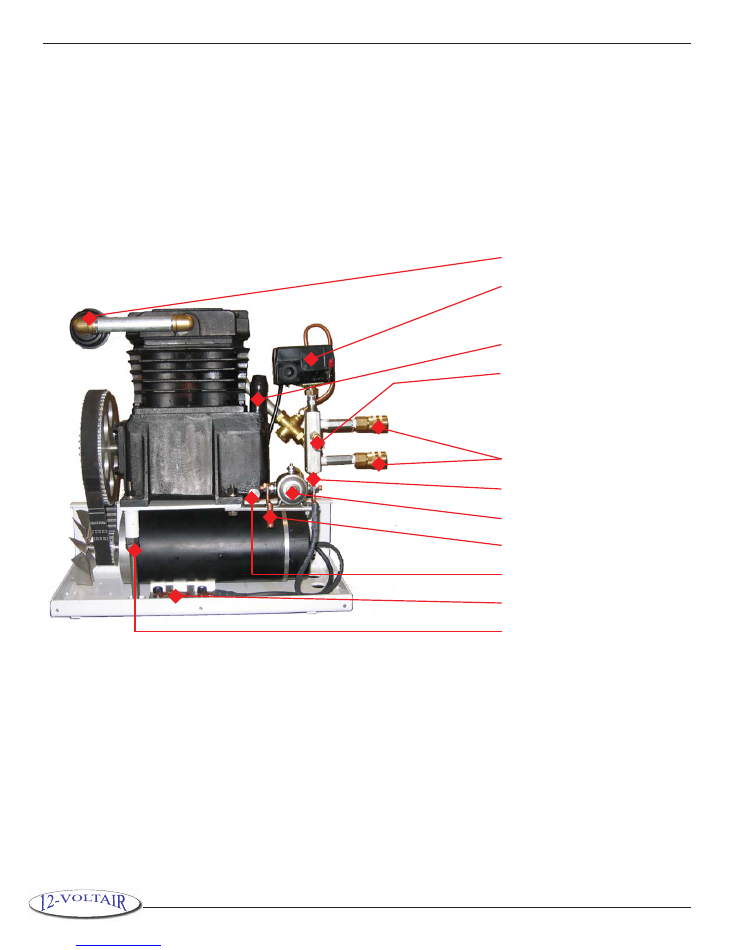

BEFORE YOU BEgIN

Thank you for selecting the 12-VOLTAIR air compressor. The 12-VOLTAIR is a heavy duty air compressor designed to let

you accomplish most air related jobs away from the shop.

For safety and benefit, read this manual carefully before using the 12-VOLTAIR.

Air Filter

Pressure Switch

Oil Fill / Oil Dipstick

Pop Off Safety Valve

Quick Coupler Outlets

Storage Tank Inlet

Solenoid

Attach Positive Wire Here

Oil Drain

Attach ground Wire Here

Adjust Belt Tension Here

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page

ASSEMBLY

Be sure to check over the 12-Voltair and inspect for any damages.

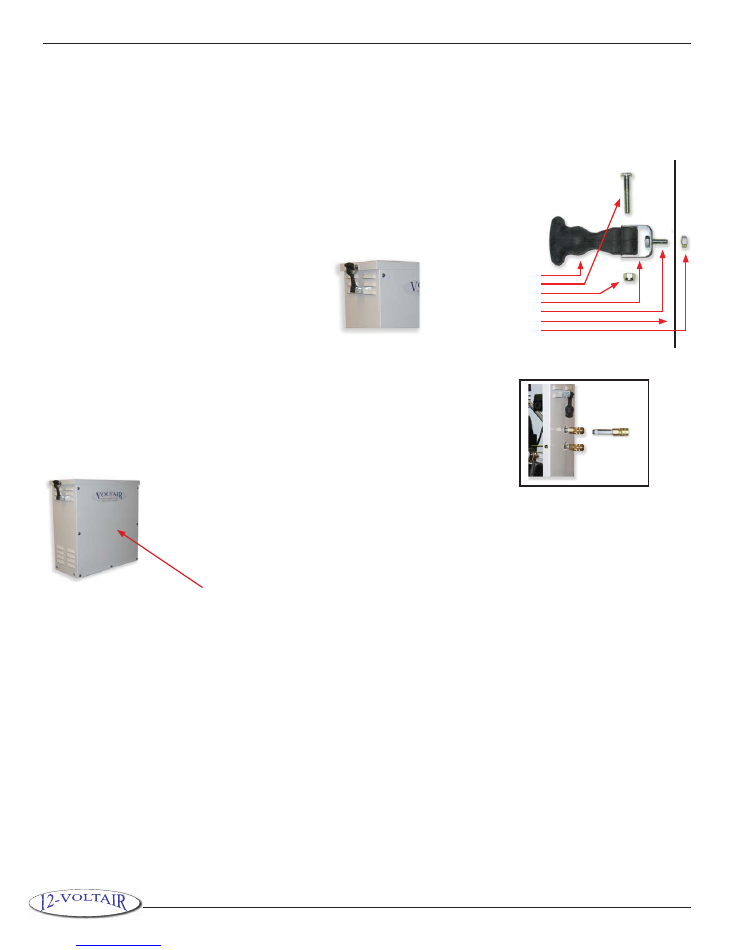

1. Side Latches

Use the provided 1/4” x 1” bolt, lock washer and nut to secure the anchor bracket to the

outside of the compressor. Once the anchor bracket has been secured use the 1/4” x

1 1/4” bolt and 1/4” lock nut to secure the rubber hold down in-between the ears of the

anchor bracket.

2. Quick Coupler

Install the threaded nipple and quick coupler into the right side of the compressor

through the two holes of the 12-Voltair cabinet.

3. Remove Service Panel

- remove the 7 screws that hold the front service panel on the 12-Voltair. Once removed,

there is no need to reattach until your installation is complete.

4. Check Belt Tension

- Although the 12-Voltair has been shipped with the proper amount of belt tension, please

check to make sure that it has not come loose during shipping.

5. Check Oil

- The 12-Voltair is not shipped with any oil. It takes approximately 2 cups of oil to fill compressor to the

full level on the dipstick. Do not overfill. See specs below on what oil should be used.

-20F - 70F (-7C - 21C) 10W non detergent compressor oil

50F - 110F (10C - 73C) 30W non detergent compressor oil

-20F - 110F (-7C - 73C) 40W synthetic non detergent compressor oil

Voltair recommends the use of synthetic non detergent compressor oil for year around use

.

Amsoil is just one manufacturer that can provide this oil (800) 96-69 - part #PCKQT

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 6

Rubber Hold Down

1/4” x 1 1/4” Bolt

1/4” Lock Nut

Anchor Bracket

1/4” x 1” Bolt

Cabinet side

1/4” Nut

In finding a loc

ation for your compressor...

1. Find a location in which the 12-Voltair can get adequate ventilation.

2. Find a location in which the 12-Voltair will not be overly exposed to dirt and dust.

3. Find a location in which the 12-Voltair can be properly fastened to ensure that it does not shift.

4. Check the underside to make sure that any drilling of holes will not interfere with existing lines or structure.

CAUTION:

U

se

gOOd

COmmON

seNse

wheN

INsTAllINg

The

12-V

OlTAIr

. w

heN

drIllINg

hOles

fOr

mOUNTINg

,

e

leCTrICAl

ANd

plUmbINg

,

be

sUre

TO

CheCk

The

UNdersIde

TO

mAke

sUre

yOUr

drIll

wIll

NOT

INTerfere

Or

dAmAge

exIsTINg

lINes

,

hOses

Or

sTrUCTUre

.

HoW BIG oF A Hole SHoUld I dRIll?

To eliminate any potential problems,

Voltair recommends adding extra protection around the wires and hose (such

as running the wires and hose through another hose, or use a rubber grommet).

However you decide, drill a hole at least 1/8” bigger than the outside diameter

of the hose/wires that will be run through the floor of your location.

Once the 12-Voltair is securely fastened to the vehicle go to next page.

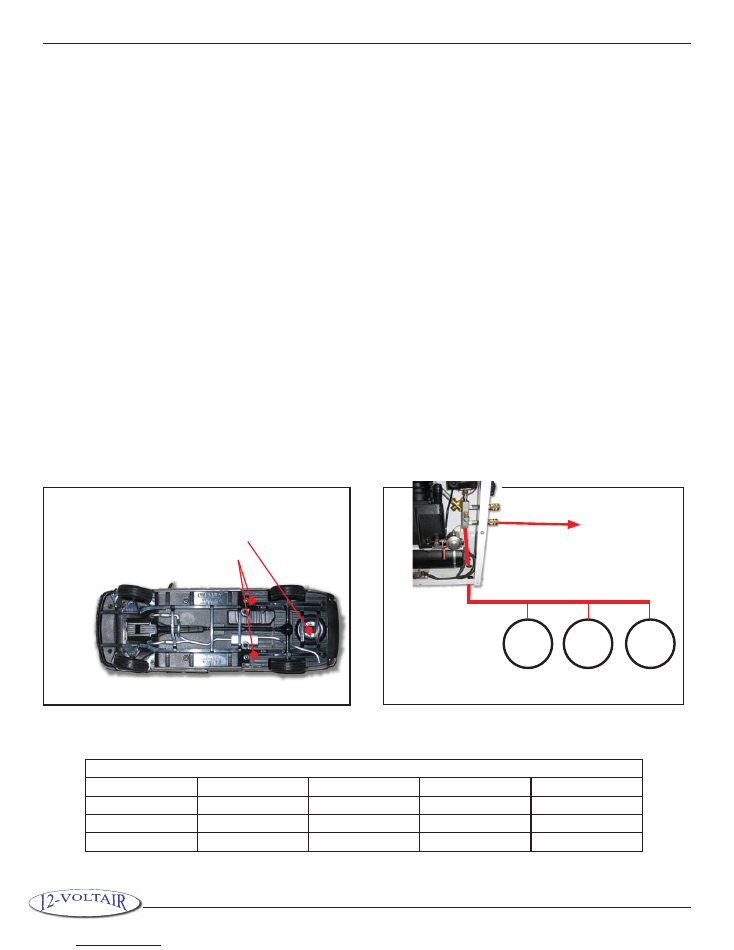

FINDINg A LOCATION

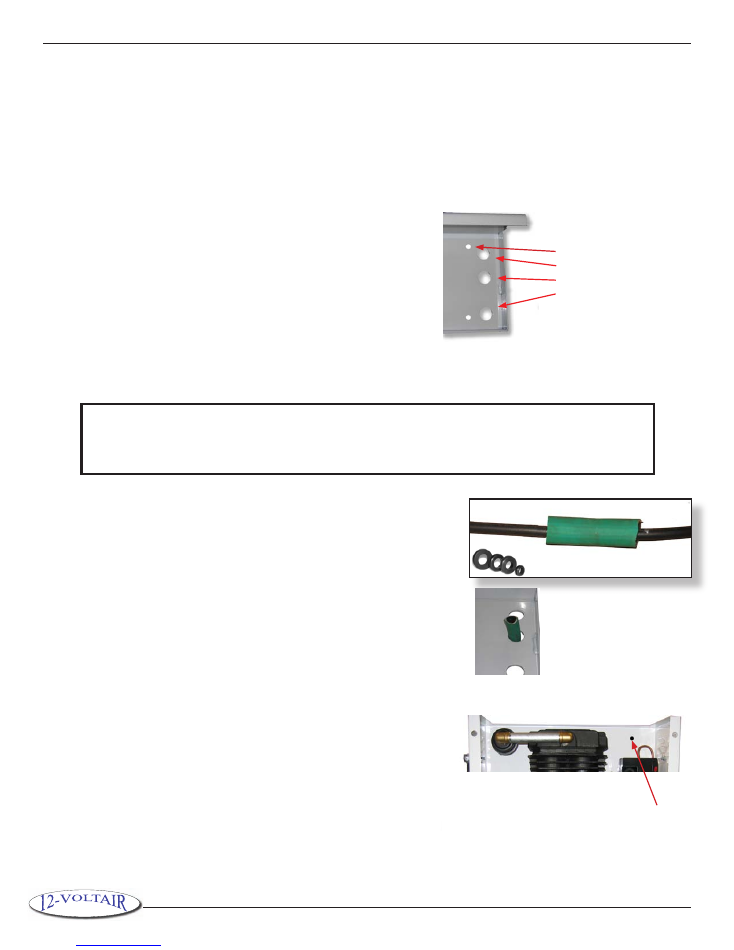

Once you have decided on a location for the 12-Voltair...

1) Set the unit into position

2) Mark the 3 holes on the right side of the compressor base

onto the floor of your location.

3) Mark the 4 mounting holes of the base of the 12-Voltair on

the floor of your location

4) Set the unit aside and get ready to drill some holes

5) Drill your holes

- 3/8” hole for 5/16” x 1 1/2” mounting bolts

- holes for electrical and plumbing

6) Once your holes are drilled, move the 12-Voltair back into position

and use the provided 5/16” x 1 1/2” bolts, lock washer and nut to

secure it to the floor. If possible also drill through the side of the

12-Voltair cabinet to secure it at a higher point.

a) Deck Mount- use all 4 mounting holes in base of the 12-

Voltair frame.

b) Bed Side Mount- use at least 2 of the for mounting

holes on the base of the 12-Voltair as well as 2

holes higher up on the back of cabinet as shown in the

above diagram.

Here is an example of securing the cabinet ‘at a

higher point’ for a bed side mount

Here is an example of

protecting wires by either

using ‘another hose’ or

‘rubber grommet.’

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page

Mounting Holes

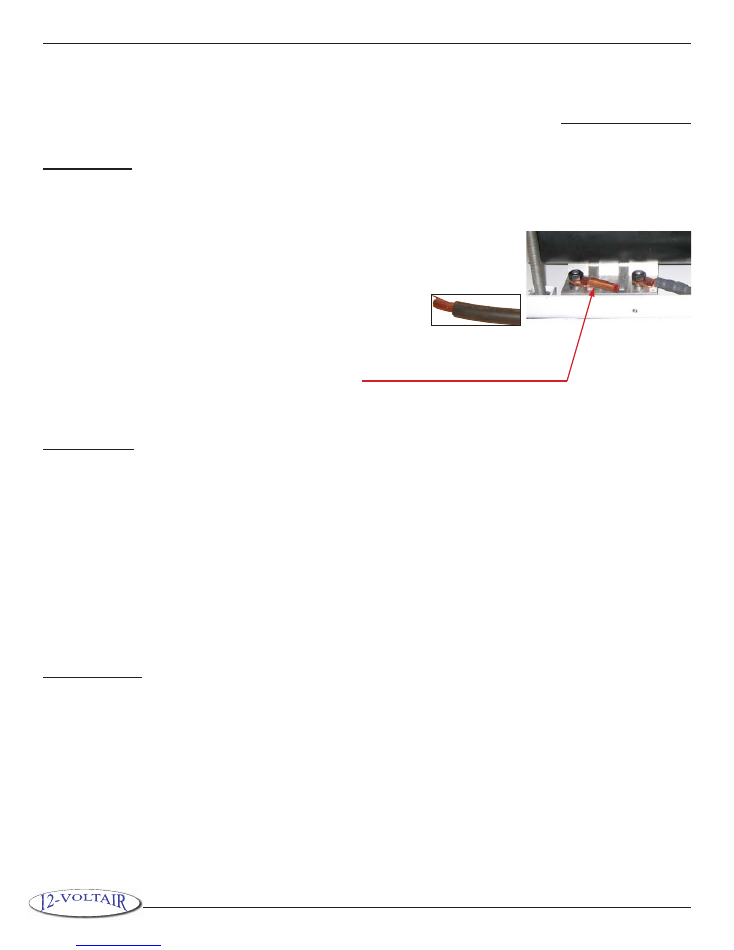

ground Wire

Air Line

Positive Wire

ELECTRICAL

W

hat Size of Wire Should I Use?

A minimum of 4 gauge copper battery cable should be used for both positive and ground

wire lengths up to 15 foot. For lengths of 15’ - 30’ use 2 gauge or 1 O copper wire

GROUnd WIRe

IN most cases a short ground cable from the 12-Voltair to the frame of your vehicle is sufficient. When securing a ground

to the frame of a vehicle be sure to sand/grind metal ‘shinny’ to ensure that the ground makes good contact. REMEMBER:

When working with 12-Volt DC your positive connection is only as good as your ground. In other words, if you have a ‘weak’

ground connection you will not be able to get peak energy through the positive wire to the

12-Voltair.

Step 1

Run the wire from the bottom of the vehicle up through

the back hole of the 12-Voltair base.

Step 2

Strip back about 3/4” of the outer covering of the

battery cable and attach and secure to the ‘loose’ copper lug,

at the base of the motor, by either soldering or crimping.

Wrap the connection with electrical tape to complete the job, ‘well done!’

Step 3

Secure to the bolt on the base of the motor

Step 4

Run other end of the ground wire along frame of vehicle to ground location and secure. Be sure to use

plastic tie straps to secure wire against frame.

POSITIVe WIRe

This wire should be run directly from the battery of the vehicle to the left side of the solenoid in the 12-Voltair. When running

this wire be sure to keep it away from moving parts and exhaust. kEEP IN MIND that if the outer sheath of the battery cable

wears through and makes contact with metal it will create a short and could cause major damage.

Step 1

Run wire from the bottom of the vehicle up through the front hole of the 12-Voltair base.

Step 2

Strip back about 3/4” of the outer covering of the battery cable and attach and secure to the copper

lug by either soldering or crimping. Wrap the connection with electrical tape to complete the job, ‘well done!’

Step 3

Attach to the left side of the solenoid. Be sure that the copper eyelet is not making contact with any

other metal objects.

Step 4

Run other end of positive wire along frame of vehicle to the positive side of the battery. Be sure to use

plastic tie straps to secure wire against frame. DO NOT USE WIRE.

BATTeRY FACTS

1. The OEM (Original Equipment Battery) that came with the purchase of your vehicle is only designed to keep up with the

demand of the vehicle. For optimum performance, Voltair recommends replacing your battery with a battery that is rated

with 120 or more minutes of reserve.

2. The alternator that comes standard in most vehicles will charge between 40-50 amps at a vehicle idle. Since the Voltair

draws 80 amps when in use, Voltair recommends a good battery and in some cases a second battery maybe necessary.

3. Voltair recommends a battery with 120 or more minutes of reserve. The 12-Voltair air compressor does not need cranking

amps for optimum performance, but it does need battery reserve.

4. Over time a battery’s ability to hold a full charge greatly diminishes. A lead battery may need to be replaced every 2 years

and an optima battery may need to be replaced every 4 years.

5. If you are using or planning to use the 12-Voltair for more than 3-4 hours on a day-to-day basis adding a second battery

will help in achieving optimum performance

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 8

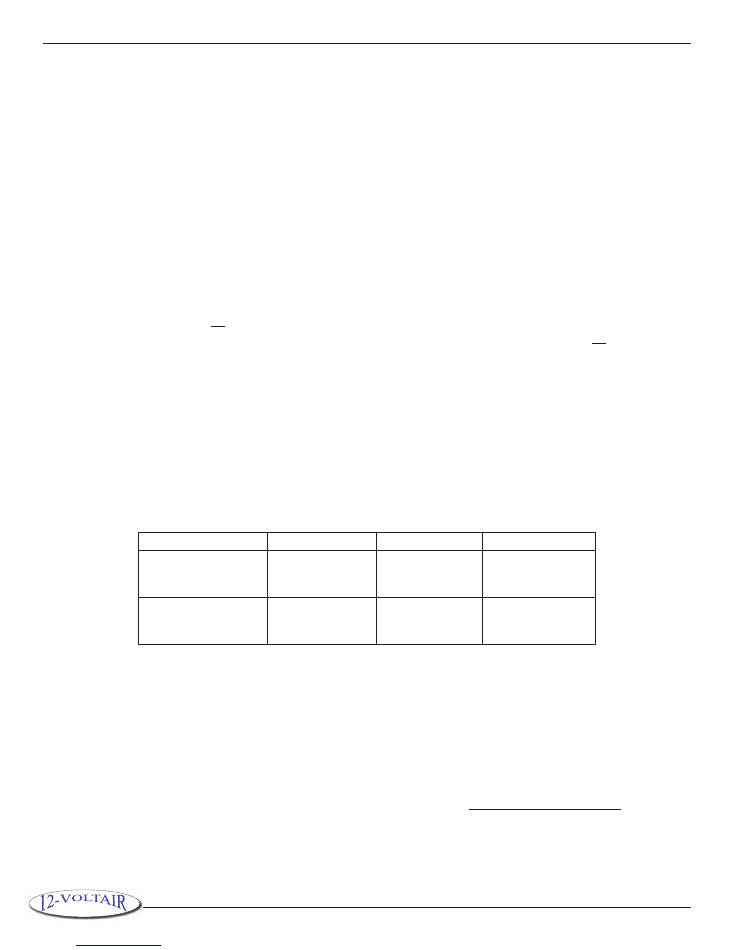

ELECTRICAL

(o P T i o n A l )

TOGGLe SWITCH

The Voltair is designed/manufactured with the solenoid activating the pressure switch. By default, when the pressure switch

is in the on position, the Voltair will run whether the vehicle ignition is on or off. If your system would drop below 125 PSI,

the compressor would kick on and run until the pressure reached 150- regardless of whether or not you are in the vehicle or

not. To avoid this, Voltair, Inc. recommends installing a remote toggle switch and powering this switch with a keyed ignition

power source. This way, the 12-Voltair will only run if both this switch and ignition are in the on position.

To turn the 12-Voltair on and off from a convenient location (i.e.- inside your vehicle) follow the steps below

Step 1

Run an 18 gauge wire from the bottom of the vehicle up through one of the three holes of the 12-

Voltair.

Step 2

Remove the wire from the left side of the solenoid (the same terminal that the wire from the vehicle

is hooked to) and connect to the wire you just pulled up.

Step 3

Run the other end of the 18 gauge wire to the location (wherever you see fit to put the toggle switch)

of the toggle switch and connect to one of the terminals.

Step 4

Run a wire from the other terminal of the toggle switch to a 12-volt power source. Preferably a power

source that only has power when the keyed ignition is in the on position. Consult your automobile manufacture to

assist you in locating a 12 VDC power source, that only has power when the ignition is in the ‘on’ position.

YOUR SWITCH SHOULd Be ReAdY TO GO

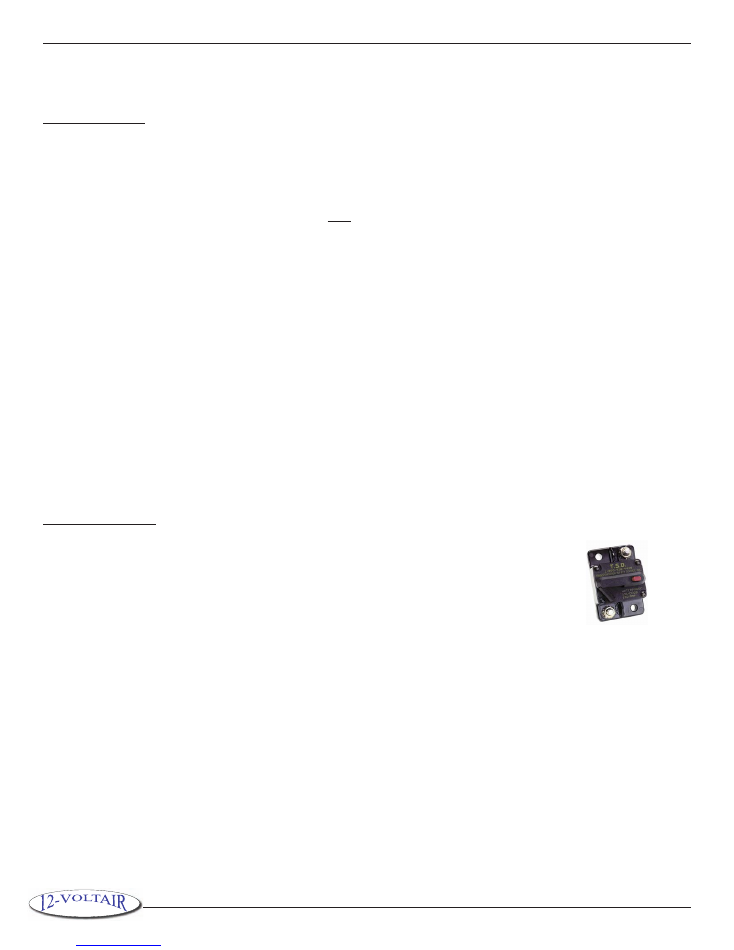

CIRCUIT BReAkeR

One way to protect against the positive wire shorting is installing a circuit breaker. Voltair recommends

a 150 amp circuit breaker. AW Direct is just one dealer who can be reached at (800) 243-3194 Part

#SCB-150. This is a device that is mounted right next to your battery that will trip in the event that

you have a wire that would short out.

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 9

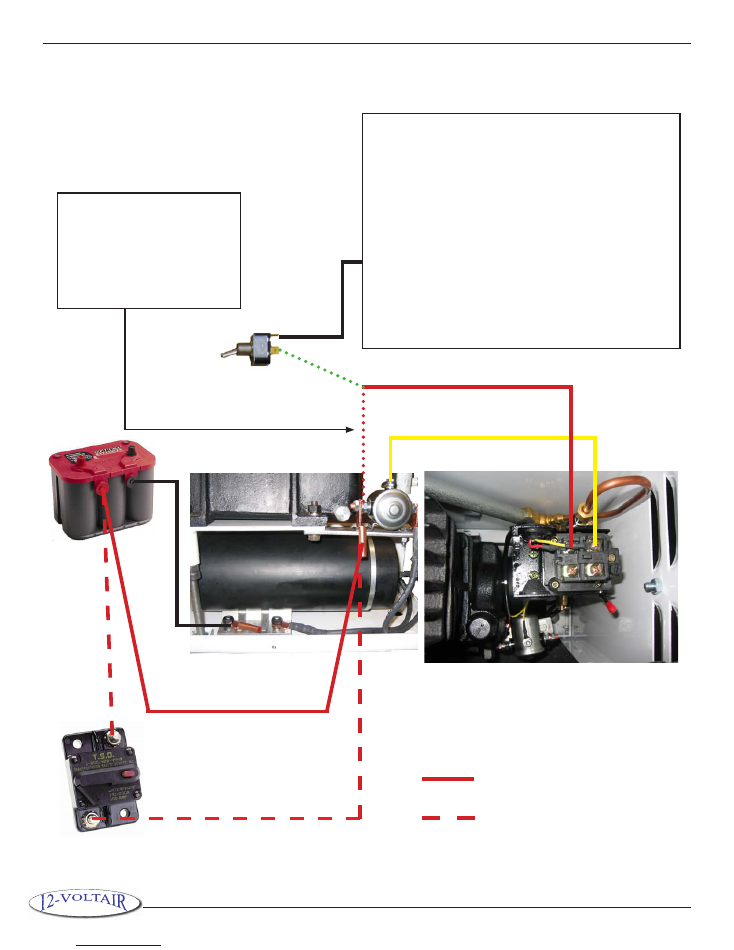

PLUMBINg

Choosing the right size

air storage tank. How much air storage you need can vary from task to task. In most cases a

10 gallon tank is adequate for filling/changing 1-2 tires at a time. Anything larger than 40 gallons is not recommended by

Voltair. See chart below to help you determine how much air storage you need.

Choosing a location for your air storage tank.

The great thing about air is that the inlet and outlet are one in the

same. It is possible to plumb 2 or three tanks together with minimal fittings and confusion (see diagram 8.4)

If you are mounting an air tank in an out of the way place then running your air hose from the compressor to your air stor-

age through the floor is the best way to go. This hose will be run through the middle hole of the 12-Voltair base.

Step 1

Mount tank. See chart to determine how much air storage you need

Step 2

Anytime an air storage tank is to be mounted on a mobile vehicle, Voltair recommends using a D.O.T.

(Department of Transportation) approved air storage tank.

(i.e.- brake tanks from semi trucks)

Step 3

Remove plug on bottom of manifold where the two quick couplers were screwed into

Step 4

Run hose from the bottom of the vehicle up through the middle hole of the 12-Voltair base and attach to

manifold where plug was removed.

Step 5

Connect the other end of the hose to the air storage tank.

VOLTAIR, InC. ReCOmmendS USInG A d.O.T APPROVed AIR STORAGe TAnkS

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 10

Time It Take To Fill Air Storage Tank

10 Gallon

20 Gallon

30 Gallon

40 Gallon

0-150 PSI

3 min

6 min

9 min

12 min

125-150 PSI

45 sec

90 sec

2 min 15 sec

3 min

Notes

Minimum Size

Maximum Size

Tank Tank Tank

1

2 3

Air Hose Plumbing

A couple ideas for where to mount air tanks are

1) Remove Spare Tire

2) Along Frame Rails

MAINTENANCE

Under optimum conditions you can count on your 12-Voltair to provide “Air Where And When You Need It!” for a long, long

time.

Check the items below atleast once a year or every 300 hours of use.

Check air filter and replace as needed

Check oil level

Drain oil and replace if using a petroleum based non-detergent compressor oil

If you are using a synthetic based compressor oil drain oil every 3 years or 600 hours

Check Belt to make sure that it there is adequate belt tension

Check pump pulley to make sure that side flanges are securely fastened

Remove any debris that may have fallen inside the case of the 12-Voltair

Check positive (wire attached to left terminal of solenoid) to make sure that there is not any excessive wear and is

still securely fastened.

Check plumbing to make sure that there are not any air leaks

To order parts consult your dealer or call (402) 723-4985

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 11

WIRINg

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 12

OPTIONAL

REMOTE SWITCH

OPTIONAL

12 VdC POWeR SOURCe

This can be any 12 power source. There are two types

of power sources.

1- Direct- This is a power source that has continuous 12

VDC whether the ignition is on or off. The disadvantage

of this is that if the switch is left on over the weekend

and an air leak were to develop- the 12-Voltair will run

to maintain air pressure and may leave you with a dead

battery when you get back.

2- Ignition Controlled- This is a power source that only

has 12 VDC power when the keyed ignition is in the on

position. The advantage of this is that the 12-Voltair will

only run when the ignition in on. Consult your vehicle

manufacture to help you locate an ignition controlled 12

VDC.

Disconnect (red dotted) wire

from the solenoid and reattach

to the wire that goes from the

pressure switch to the wire

(green dotted) that goes to the

toggle switch.

Follow this line if you are not using a circuit

breaker.

Use this dotted line if you are using a circuit

breaker.

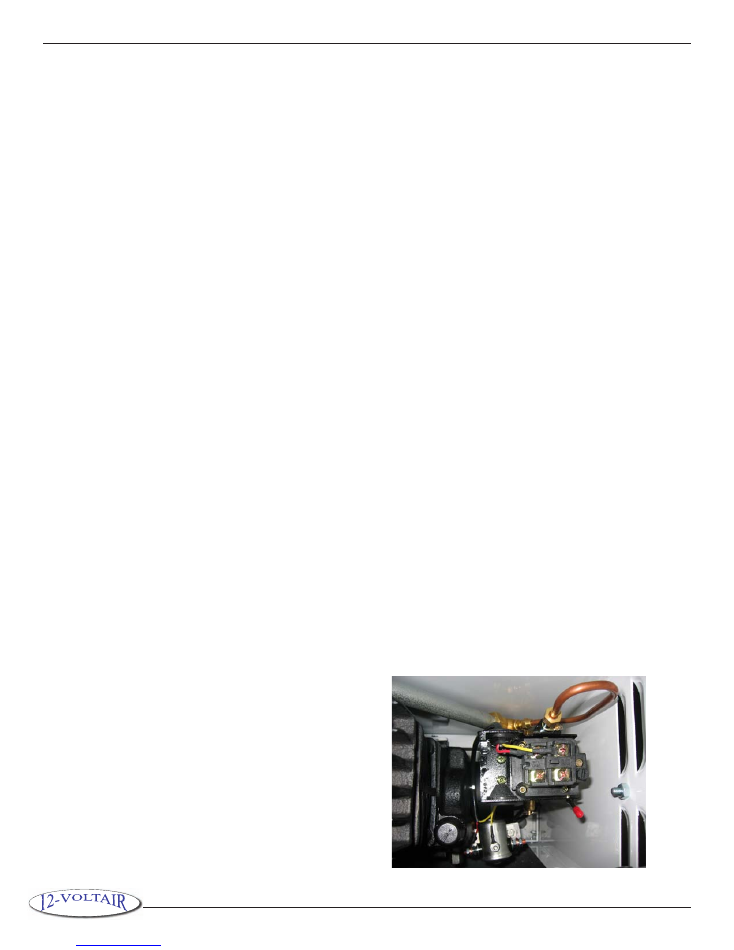

TROUBLESHOOTINg

mY 12-VOLTAIR nOT RUn

1. Check if the switch on the pressure switch is in the auto (down) position

2. Check the air pressure. If you have more than 120 PSI in the compressor, the compressor will not kick in

and run until the pressure has dropped below 120 PSI

Before proceeding with this troubleshooting guide, be sure to disconnect the wire on the right

side of the solenoid. This is the wire that goes to the inside of the motor.

3. Do you have a toggle switch? If not skip to 4.

- Check if the toggle switch is in the on position

- Check your wiring against the wire diagram on previous page

- Check with a volt meter that you have voltage on at least one side of the switch (10-14 VDC) when the

switch is in the off position

- Check to see if you have voltage on both sides of the switch when the switch is in the on position

4. Do you have a circuit breaker? If not skip to 5.

- Check to see if there is a reset on the circuit breaker

- Check to see if you have voltage on both sides of the circuit breaker (10-14 VDC)

5. Check to see if the solenoid is working

- Make sure the circuit breaker is engaged, the remote switch is on

- Make sure the switch is in the off position

- Put you hand on the top side of the solenoid with one hand and turn the switch on the pressure switch

on with the other hand. You should feel a click. If not you possibly have a bad solenoid. Double check

with the next step

(Be sure the wire on the right side of the solenoid is disconnected)

- With a volt meter check the solenoid using the two different sceneries

Scenario

Left Post

Top Post

Right Post

Circuit breaker on

Remote Switch on

Pressure switch off

10-14 VDC

0 VDC

0 VDC

Circuit breaker on

Remote Switch on

Pressure switch on

10-14 VDC

10-14 VDC

10-14 VDC

dIAGnOSIS

- If you don’t get voltage on the top post in scenario #2 you have a bad pressure switch

- If you don’t get voltage of the right post in scenario #2 you have a bad solenoid

6. Was the compressor running and just quit?

- If the motor overheated (surface temp over 190F) than the thermal protector will have shut the

system down until the temperature drops below 170F. This may take up to 30 minutes.

WARNING:

This is an automatic reset thermal protector- If all switches are on, and the thermal protector resets it

will run without any warning. Never put hand in the box without

first disconnecting the power

.

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 1

TROUBLESHOOTINg

mY 12-VOLTAIR SHAkeS A LOT.

1. Check to make sure there is adequate belt tension. You should have anywhere from 1/4” - 3/8” movement

when applying 50% pressure to the belt directly between the motor and pump pulleys

2. Check to make sure that the motor and compressor are securely fastened to the frame. Make sure that bolts

have not come loose.

mY 12-VOLTAIR RUnS BUT IS nOT ABLe TO PUmP UP AnY PReSSURe

1. Check to see if you have any external air leaks

- Disconnect any air storage tanks and plug tank supply line and run compressor to see if pressure

builds up

- If this fixes the problem you have a leak that needs to be fixed

mY 12-VOLTAIR jUST STARTS - STOPS - STARTS - STOPS

1. You probably don’t have an external air storage supply tank. The compressor is shutting down with 150

PSI in the air lines and a small leak is draining the pressure down to 125 PSI and the compressor is

kicking back on to build the pressure back up to 150 PSI.

mY COmPReSSOR RUnS FAST AT BeGInnInG BUT SOUndS LIke IT SLOWS dOWn AFTeR IT HAS RUn FOR 5,

10, 15 mInUTeS.

BATTERY

STEP 1 Recharge battery to make sure you have a good full charge if the problem still exists- STEP 2

STEP 2 Replace battery with a new battery. See battery facts on page 8 - if this does not

fix that problem- STEP 3

STEP 3 Check your alternator.

OPTION 1- Take it to a mechanic for him to check

OPTION 2- With an DC amp meter and the vehicle running, check the wire between the battery

and the alternator to see if the alternator is charging

WHen RUnnInG THe 12-VOLTAIR FOR exTended PeRIOdS OF TIme, mY VeHICLe jUST SHUTS OFF

BATTERY- check the steps above to diagnose a problem

HOW dO I AdjUST mY PReSSURe SWITCH

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 1

WARR ANTY

12-Voltair Warranty Card

Voltair, Inc. would like to congratulate you on your purchase of the best 12 Volt Air compressor on the market. Please

take the time to fill out this information and return to Voltair, Inc. By filling out this form we can help keep track of your

purpose as well as assist us in learning how this product is being used.

Name

Address

City

State

zip

Phone Number

Fax Number

mOdeL # 12V6CF

SeRIAL #

located on the right side of the base of the 12-Voltair, just below the back of the motor

1. Who Installed the 12-Voltair

Customer Dealer

2. How often do you plan to use your 12-Voltair?

Daily

Weekly Monthly

3. What of the following best describes the area in which you will be operating this compressor?

Check all that apply

Aerial

Management Co.’s

Off-road

Aerial

Forestry

Oil field/Gas

Auto Parts stores

Fuel/Lube

Road Repair

Catalog firms

Government

Rural Fire Departments

Companies with fleet of vehicles

Law Enforcement

Towing Associations

Contractor

Manufacturer OEM

Towing Companies

Crane

Military

Truck parts stores

Fish & Game Departments

Mobile Detailing & Trim firms

Other ____________________

Fleet Maintenance

Municipalities

mail Completed Form to

Voltair, Inc.

515 Road 11

York, NE 68467

FAx Completed Form to

(810) 885-8284

download

form from

www.12-Voltair.com/warrantycard

e-mail Completed Form to

info@12-Voltair.com

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 1

T

hank-You for your pur c has e. We

s i nc er ely ho p e that your 12-Vo l tai r

wi l l pr ovide you wi th “A i r W her e

A nd W hen You n eed i t! ”

T he Vo l tai r Team

“ A i r W h e re A n d W h e n Yo u N e e d I t ! ”

®

Page 16